ஓட்டுக்குழு எப்படி வண்டியின் மெதுவும் குருவியும் உற்பத்தியில் பயன்படுகிறது

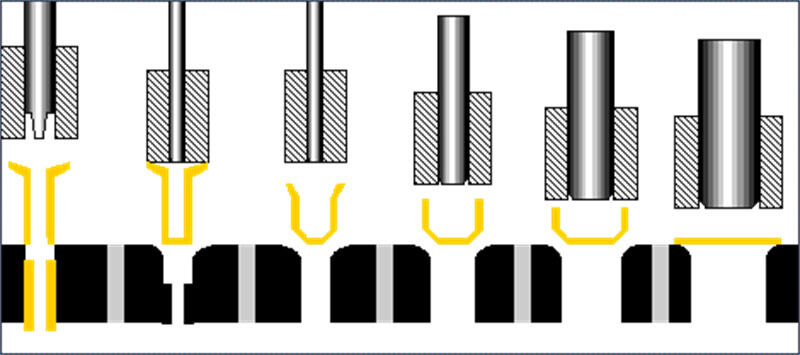

வண்டி தயாரிப்பு தொழில்நுட்பத்தில், metal stamping automotive பகுதிகள் வண்டிகளுக்கான முக்கிய உறுப்புகளை தயாரிக்கும் போது அவசியமானவை. வாகன முத்திரை பகுதிகளை உருவாக்கும் முறை ஒரு மெடல் பத்திரத்தின் மீது அழுத்தத்தை தேர்ந்தெடுப்பதாகும், அதன் வடிவமைப்பு விரும்பும் வடிவத்திற்கு மாற்றும். இந்த முறை வண்டியின் அமைப்பு ஒருங்கிணைப்பு, பாதுகாப்பு மற்றும் மொத்த திறனுக்கு பங்களிக்கும் உறுப்புகளை தயாரிக்கும் போது முக்கியமானது. இந்த பத்திரிக்கையில், நாங்கள் எப்படி வண்டி செய்திகள் அழுத்து அமைப்பு தொழில்நுட்பம் பயன்படுத்தப்படுகிறது வண்டி உடற்பால் மற்றும் சாஸிஸ் பகுதிகளின் உற்பத்தியில்.

நடுவர் செய்திகள் பகுதிகளின் பங்கு வண்டி உடற்பால் மற்றும் அடிப்படை உற்பத்தியில்

வண்டி உற்பத்தியில் கூட, அது நடுக்குழாய் உடைமை மற்றும் சாஸிஸ் எந்த வண்டியின் அடிப்படை உறுப்புகளும் அவை. இந்த உறுப்புகள் வண்டி திறன், பாதுகாப்பு மற்றும் எரியும் தூசியின் செலுத்தல் அளவை உறுதி செய்ய சிலருக்கு மிகச் சிறுமையாகவும், மற்றும் நீண்ட காலகளுக்கும் சாதகமாகவும் இருக்க வேண்டும்.

வாகன முத்திரை பகுதிகள் உறுதியாக தீர்மானிக்கப்படுகின்றன வண்டி உடற்பால் மற்றும் சாஸிஸ் அறிமுகமாக்கும் தேவைகளுக்கு. பால் பலகங்கள், போர்ஸ்டர் பலகங்கள் மற்றும் செய்திகள் அடிக்கடி உற்பத்தி செய்யப்படுகின்றன தங்க அடிப்படைச் சேவைகள் . அ தாமரை சினைப்பு பகுதிகள் இந்த செயலில் உற்பத்தி செய்யப்படும் பகுதிகள் வண்டியின் தேவைகளுக்கு சரியாக வடிவமைக்கப்படுகின்றன.

தங்க அடிப்படைச் சேவைகள்

உதாரணமாக, வண்டி செய்திகள் அழுத்து அமைப்பு தாமரை சினைப்பு செயலி நான்காவது பலகங்கள் , ரூப் பலகங்கள் , மற்றும் புதிர்கள் , அழகிய மற்றும் செயலாக்குவதற்கு இரண்டு நோக்குகளுக்கும் பயன்படுகின்றன. இந்த பகுதிகள் கடுமையான தாக்கத்தில், நெடுநேர்வு மற்றும் அளவுரு சரிவு நிலைகளை நிறைவேற வேண்டும்.

அட்டாச்சி உறுதியில் அங்கத்தினர் முகவரிகளுக்கான உறுதி ஏன் அவசியம்

உறுதி முகவரிகளின் உற்பத்தியில் முக்கியமானது. வண்டி செய்திகள் அழுத்து அமைப்பு இது உறுதியாக தயாரிப்பாளர்களுக்கு அனுமதி தருகிறது தாமரை சினைப்பு பகுதிகள் துல்லிய அளவுகளுடன், முகவரிகள் முக்கியமாக சேர்க்கப்படுகின்றன. இந்த உறுதி வாகனத்தின் அமைப்பு ஒருங்கிணைவு மற்றும் காண்கிற அழகியின் மூலம் முக்கியமாக உள்ளது. மேலும், உறுதி metal stamping automotive உறுதியான வேகமாக பகுதிகள் உற்பத்தி செய்யப்படுகின்றன அதன் தரத்தை மாற்றாமல்.

அட்டாச்சி உறுதியில் வாகன உறுதியின் உற்பத்தி

வாகன உறுதியின் உறுதியில் உலை உறுதியின் பாட்டுகள்

முக்கிய காரணிகளில் ஒன்று metal stamping automotive நடுவர் உடைகளின் தயாரிப்பில் பகுதிகள் பயன்படுத்தப்படும் காரணம் அதிக முறையான உறுப்புகளை வேகமாக உற்பத்தி செய்யும் திறன். அடிப்படை பகுதிகள் தயாரிப்பாளர்கள் முன்னெடுக்கப்பட்ட வண்டி செய்திகள் அழுத்து அமைப்பு சாதனங்களை பயன்படுத்தி, சீருந்தான தரத்தை கொண்ட பகுதிகளை உருவாக்குகின்றன, இது நடுவர் தொகுதியின் அதிக உற்பத்திக்கு அவசியமானது.

இதன் குறியீட்டு விளக்கமாக தாமரை சினைப்பு பகுதிகள் தேவையான தாக்கம் வழங்குவதோடு, நடுவரின் மொத்த திரளத்தைக் குறைப்பதையும் உறுதிப்படுத்துகிறது. இந்த சமா蘅்சம், எரிவாய்த்து செலவை உயர்த்துவதற்கும், சூழல் மாறிலிகளை நிறைவேற்றுவதற்கும் முக்கியமாக உள்ளது. முன்னெடுக்கப்பட்ட வண்டி செய்திகள் அழுத்து அமைப்பு சாதனங்கள் தயாரிப்பாளர்களுக்கு சிக்கலான வடிவங்களை, போலி அல்லது வளைந்த மேற்கோள்களை உருவாக்குவதில் அதிக முறையும், குறைந்த அழுத்தத்துடனும் அனுமதி செய்கின்றன.

இருப்பு அடிக்கல் மாதிரிகளின் வேகமான உற்பத்தி

இருப்பு அடிக்கல் மூலம் செலவேற்றமான மதிய உற்பத்தி

தங்க அடிப்படைச் சேவைகள் மிகவும் வேகமாக மற்றும் செலவுத்தாரமாக பல எண்ணிக்கையிலான பகுதிகளை உற்பத்தி செய்யும் ஒரு கூடுதல் முறையை வழங்குகின்றன. உபயோகிக்கும் வண்டி செய்திகள் அழுத்து அமைப்பு தொழில்நுட்பம், தயாரிப்பாளர்கள் உயர் அளவு வேலைகளை நிரம்பிக்க முடியும் கொண்டால் உயர் தரம் அடிப்படையில் வைத்துக்கொள்ளும், அது போட்டியான கார் தொழில்நுட்ப வீதியில் அவசியமானது.

நான்கு அடிப்படை உற்பத்திகள் தங்க அடிப்படை வாகன அடிப்படையில்

வாகன அடிப்படை அம்புகள் , வாகன முத்திரை பகுதிகள் கட்டமைப்பு உறுப்புகளை உருவாக்க பயன்படுத்தப்படுகின்றன அம்புகள், உப-பேரம், மற்றும் சுஸ்பென்ஷன் அம்புகள். இந்த பகுதிகள் வாகனத்தின் மொத்த தாக்கமும் மற்றும் கட்டிடமாக இருக்கும் அளவும் உறுதிப்படுத்துவதற்கு முக்கியமானவை.

தங்க அடிப்படைச் சேவைகள் செயல்படுத்து அடிப்படை பகுதிகள் தயாரிப்பாளர்கள் அதிக அளவிலான முக்கிய பகுதிகள் தேவையானவை அடிப்படை விதிகளுக்கு உற்பத்தி செய்யும். உறுப்புகள் போன்ற சாசிஸ் ரேல்கள் மற்றும் கரை பன்கள் அதிக தாக்கமுறு தேவைகளுக்கும், ச本தி மாறாத நிறுவனத்தின் மூலமும் உணர்வு மற்றும் அதிக உற்பத்தியில் செலுத்தப்படுகின்றன. தாமரை சினைப்பு பகுதிகள் அவற்றின் அதிக தாக்கமுறு தேவைகளுக்கும், சதி மாறாத நிறுவனத்தின் மூலமும் உணர்வு மற்றும் அதிக உற்பத்தியில் செலுத்தப்படுகின்றன.

சாசிஸ் உறுப்புகளில் அதிக உணர்வின் பங்கு

உறுப்புகளை உருவாக்கும்போது சாஸிஸ் உறுப்புகள், அவற்றின் உறுப்புகள் அதிக உணர்வுடனும் மற்றும் நீண்ட காலம் வரையும் தாக்கும் தன்மையுடனும் இருக்க வேண்டும். வண்டி செய்திகள் அழுத்து அமைப்பு தொழில்நுட்பம் அனுமதி metal stamping automotive உறுப்புகள் அமைப்பு உறுப்புகளுக்கான கட்டாயமான தேவைகளை நிறைவேற்றுவதற்கு உதவுகிறது. இது வாகனத்தின் மொத்த தாக்கும் தன்மையும் பாதுகாப்பும் உறுதிப்படுத்துகிறது, எனவே சாசிஸ் உறுப்புகள் உற்பத்தியின் மையமாக அமைந்துள்ளது.

இயந்திர அறிமுகப்படுத்தும் சேவைகளை மற்றும் வாகன உற்பத்தியில் ஏற்றுக்கொள்வதற்கான காரணம்?

இது அடிப்படை பகுதிகள் தயாரிப்பாளர்கள் , தருவித்து தங்க அடிப்படைச் சேவைகள் கார் தயாரிப்புக்கு மிகவும் பல அடிப்படை வorteantages தருகிறது. முதன்முதலில், உலோக சார்பு அதிக அளவிலான பகுதிகளை வேகமாக உற்பத்தி செய்யும் மிகவும் தேர்வுறு முறையாகும்.இது கார் தயாரிப்பாளர்களுக்கு கடினமான தயாரிப்பு நேர அளவுகளை நிரப்புவதில் உதவும், அதோடு அதிக தரத்தை அதிகரிக்கும்.

மேலும், முன்னெடுக்கப்பட்ட வண்டி செய்திகள் அழுத்து அமைப்பு தொழில்நுட்பம் குறைந்த தோல்விகளுடன் அதிக தரத்திலான பகுதிகள் உற்பத்திக்கு உதவுகிறது. இது கார் துรกத்தில் முக்கியமானது, ஏனெனில் பொருட்கள் கடுமையான பாதுகாப்பு மற்றும் காணும் திட்டங்களுக்கு ஒத்துக்கொள்ள வேண்டும். தங்க அடிப்படைச் சேவைகள் அத்துடன் தயாரிப்பு செலவுகளையும் குறைக்கும், தரத்தை அதிகரிக்கும், இதனால் தயாரிப்பாளர்கள் போட்டியில் தங்களை வீச முடியும்.

கார் தயாரிப்பில் செலவு மற்றும் நேர தேர்வு

இத்தொழில்நுட்பத்தை பயன்படுத்தி metal stamping automotive தொழில்நுட்பம் அடிப்படை பகுதிகள் தயாரிப்பாளர்கள் கார் பகுதிகளின் தயாரிப்பில் மிகவும் அதிகமான நேர மற்றும் செலவு சேமிப்புகளை அடைய முடியும். அது எந்த பொருளின் காரணமாக வண்டி உடற்பால் அல்லது சாஸிஸ் பொருட்கள் தாமரை சினைப்பு பகுதிகள் நம்பிக்கையாகவும் செலுத்தமான தீர்வையும் காற்று முகாம் உறுப்புக்கள் தொழில் முறையின் உயர் அளவுகளை நிறைவேற்றும்.

முடிவு: காற்று முகாம் தொழில்நுட்பத்தில் உலோக அடிப்புத் தொழில்நுட்பின் எதிர்காலம்

காற்று முகாம் தொழில்நுட்பம் மாறுபடுகிறது, உயர் திறனுடைய metal stamping automotive பகுதிகள் தேவை மேம்படுத்தும். தொழில்நுட்பத்தின் அமைப்பு வண்டி செய்திகள் அழுத்து அமைப்பு செயல்படுத்த முடியும் அடிப்படை பகுதிகள் தயாரிப்பாளர்கள் மேலும் சிக்கலான, உயர் தாக்கமுள்ள உறுப்புகளை குறைந்த செலவில் உற்பத்தி செய்ய முடியும். எங்களுக்கு வண்டி உடற்பால் அல்லது சாஸிஸ் , தாமரை சினைப்பு பகுதிகள் காற்று முகாம் தொழில்நுட்பத்தில் முக்கியமாக இருக்கும்.

தொழில்நுட்பம் மேம்படும் அதிக நேர்த்தியுடன் மற்றும் குறைந்த திட்டமான வண்டிகளுக்கு மேலும் செல்லும்போது தங்க அடிப்படைச் சேவைகள் இந்த தேவைகளை நிறைவேற்றுவதில் முக்கிய பங்கை வகிக்கும். கிடைமட்ட தீர்வுகளை வழங்குவதன் மூலம் உலோக சார்பு உயர் தரமான உற்பத்தியை நிர்வாகிக்கும், காற்று முகாம் தொழில்நுட்பத்தின் எதிர்காலத்தை வடிவமையும்.

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —

சிறு கலைகள், உயர் தரம் தரவுகள். எங்கள் வேகமான மாதிரி செயற்படுத்தும் சேவை சரிபார்ப்பை வேகமாக்கும் மற்றும் எளிதாக்கும் —