Cara Bagian Pemampatan Mobil Digunakan dalam Produksi Bodi dan Chasis Kendaraan

Dalam industri manufaktur otomotif, stempel logam otomotif bagian-bagian tersebut merupakan bagian integral untuk menghasilkan komponen utama kendaraan. Proses dari pemotongan komponen otomotif bagian melibatkan penerapan tekanan pada lembaran logam untuk membentuknya menjadi bentuk yang diinginkan. Proses ini sangat penting untuk memproduksi komponen yang berkontribusi pada integritas struktural, keselamatan, dan kinerja keseluruhan kendaraan. Dalam blog ini, kita akan menjelajahi bagaimana teknologi pres pemotongan otomotif digunakan dalam produksi bodi kendaraan serta chassis komponen.

Peran Bagian Pemotongan Otomatis dalam Produksi Bodi dan Chasis Kendaraan

Ketika berbicara tentang produksi kendaraan, bodi kendaraan serta chassis adalah elemen dasar dari setiap kendaraan. Komponen-komponen ini harus ringan namun kuat untuk memastikan kinerja, keselamatan, dan efisiensi bahan bakar kendaraan.

Pemotongan komponen otomotif bagian diproduksi untuk memenuhi persyaratan kompleks dari bodi kendaraan serta chassis produksi. Komponen seperti panel pintu, sayap, dan rangka chassis sering kali diproduksi menggunakan jasa pemipaan logam . Itu komponen stamping logam yang dihasilkan dalam proses ini dibentuk dengan presisi untuk sesuai dengan spesifikasi kendaraan.

jasa pemipaan logam

Misalnya, teknologi pres pemotongan otomotif digunakan untuk membuat panel body penting seperti quarter panels , roof panels , dan bumper , yang memiliki tujuan estetika dan fungsional. Bagian-bagian ini perlu memenuhi standar ketat kekuatan, keawetan, dan akurasi dimensi.

Mengapa Presisi Penting dalam Pemotongan Logam Otomotif untuk Panel Body

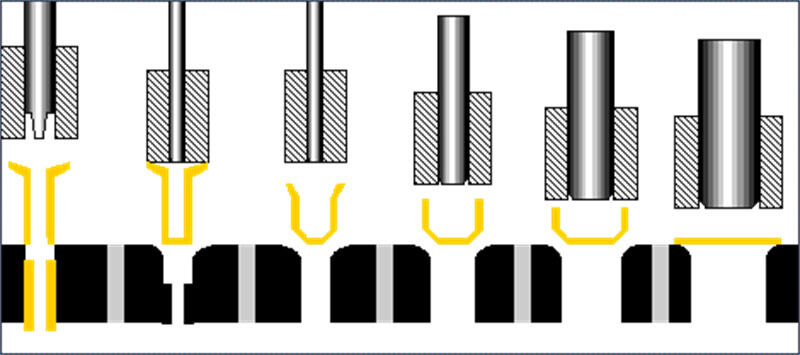

Presisi adalah kunci dalam produksi panel bodi. Yang teknologi pres pemotongan otomotif memungkinkan produsen untuk membuat komponen stamping logam dengan spesifikasi yang tepat, memastikan bahwa panel bodi cocok dengan sempurna. Presisi ini sangat penting untuk integritas struktural dan daya tarik visual kendaraan. Selain itu, akurasi dalam stempel logam otomotif memastikan bahwa bagian-bagian diproduksi dengan kecepatan tinggi tanpa mengorbankan kualitas.

Pembuatan caping otomotif

Keuntungan Pemotongan Logam dalam Produksi Bodi Kendaraan

Salah satu alasan utama stempel logam otomotif komponen digunakan dalam produksi bodi kendaraan adalah kemampuan untuk menghasilkan komponen presisi tinggi dengan cepat. Pabrik komponen stamping menggunakan teknologi canggih teknologi pres pemotongan otomotif mesin untuk membuat komponen dengan kualitas yang konsisten, yang sangat penting untuk produksi massal kendaraan.

Selain itu, komponen stamping logam menawarkan kekuatan yang diperlukan sambil menjaga berat keseluruhan kendaraan tetap rendah. Keseimbangan ini sangat penting untuk meningkatkan efisiensi bahan bakar dan memenuhi standar lingkungan. Teknologi maju teknologi pres pemotongan otomotif mesin memungkinkan produsen untuk menghasilkan bentuk kompleks, seperti permukaan melengkung atau berkontur, dengan presisi tinggi dan limbah minimal.

Produksi cepat cetakan pemipaan logam

Produksi Massal yang Hemat Biaya dengan Pemipaan Logam

Jasa pemipaan logam memberikan metode efisien untuk memproduksi jumlah besar komponen dengan cepat dan hemat biaya. Dengan menggunakan teknologi pres pemotongan otomotif teknologi, produsen dapat memenuhi permintaan dalam jumlah besar sambil tetap menjaga kualitas tinggi, yang sangat penting bagi industri otomotif yang kompetitif.

Komponen Utama yang Dihasilkan oleh Pemipaan Logam pada Chasis Kendaraan

Dalam produksi rangka kendaraan , pemotongan komponen otomotif komponen digunakan untuk membuat bagian struktural seperti anggota silang, subframe, dan penopang suspensi. Komponen-komponen ini sangat penting untuk memastikan kekuatan keseluruhan dan kekakuan kendaraan.

Jasa pemipaan logam bantuan pabrik komponen stamping memproduksi volume besar komponen presisi yang diperlukan untuk sistem rangka. Komponen seperti rel rangka serta lantai dasar umumnya diproduksi menggunakan komponen stamping logam karena persyaratan kekuatan tinggi mereka dan kebutuhan untuk produksi massal yang hemat biaya.

Peran Presisi dalam Komponen Rangka

Ketika memproduksi chassis komponen, penting bahwa bagian-bagian tersebut akurat dan tahan lama. The teknologi pres pemotongan otomotif teknologi memungkinkan stempel logam otomotif bagian untuk memenuhi spesifikasi ketat yang diperlukan untuk komponen struktural. Ini menjamin kekuatan keseluruhan kendaraan dan keselamatan, menjadikan presisi aspek vital dalam proses produksi chassis.

Mengapa Memilih Jasa Pemotongan Logam untuk Produksi Otomotif?

Untuk pabrik komponen stamping , menawarkan jasa pemipaan logam untuk produksi otomotif membawa banyak keuntungan. Pertama dan terpenting, pengetikan Logam adalah metode yang sangat efisien untuk menghasilkan jumlah besar bagian dengan cepat. Ini membantu produsen otomotif memenuhi jadwal produksi yang menuntut sambil mempertahankan standar kualitas tinggi.

Selain itu, teknologi canggih teknologi pres pemotongan otomotif menjamin produksi bagian berkualitas tinggi dengan defek minimal. Hal ini sangat penting dalam industri otomotif, di mana komponen harus mematuhi standar keselamatan dan peraturan yang ketat. Jasa pemipaan logam juga mengurangi biaya produksi sambil mempertahankan kualitas, memungkinkan produsen tetap kompetitif.

Efisiensi Biaya dan Waktu dalam Produksi Otomotif

Dengan memanfaatkan stempel logam otomotif sendiri, pabrik komponen stamping dapat mencapai penghematan waktu dan biaya yang signifikan dalam produksi komponen otomotif. Baik itu untuk bodi kendaraan atau chassis komponen, komponen stamping logam menyediakan solusi yang andal dan efisien yang memenuhi standar tinggi industri otomotif.

Kesimpulan: Masa Depan Pemipaan Logam dalam Manufaktur Otomotif

Seiring perkembangan industri otomotif, permintaan akan suku cadang berkinerja tinggi akan terus bertumbuh. Pengembangan teknologi stempel logam otomotif bagian akan terus berkembang. Pengembangan teknologi pres pemotongan otomotif teknologi akan memungkinkan pabrik komponen stamping untuk memproduksi komponen yang lebih kompleks dan kuat dengan biaya lebih rendah. Baik untuk bodi kendaraan atau chassis , komponen stamping logam akan tetap menjadi krusial dalam manufaktur otomotif.

Seiring dengan perkembangan industri menuju kendaraan yang lebih ramah lingkungan dan ringan, jasa pemipaan logam akan memainkan peran yang semakin penting dalam memenuhi permintaan ini. Dengan memberikan solusi inovatif dan produksi berkualitas tinggi, pengetikan Logam akan terus membentuk masa depan manufaktur otomotif.

Produksi dalam jumlah kecil, standar tinggi. Layanan prototipisasi cepat kami membuat validasi lebih cepat dan mudah —

Produksi dalam jumlah kecil, standar tinggi. Layanan prototipisasi cepat kami membuat validasi lebih cepat dan mudah —