Paano Ginagamit ang mga Bahagi ng Auto Stamping sa Produksyon ng Katawan at Chassis ng Sasakyan

Sa industriya ng paggawa ng automotive, metal stamping automotive mga parte ay mahalaga sa paggawa ng pangunahing komponente para sa mga siklo. Ang proseso ng presyo automotive mga parte ay naglalapat ng presyon sa isang metal na plato upang i-shape ito sa napiling anyo. Mahalagang proseso ito para sa paggawa ng mga komponente na nagdedebelop sa integridad ng estruktura, seguridad, at kabuuang pagganap ng siklo. Sa blog na ito, tatalkin namin kung paano ginagamit ang automotive stamping press teknolohiya sa produksyon ng katawan ng siklo at chassis mga bahagi.

Ang Papel ng mga Auto Stamping Parts sa Produksyon ng Katawan at Chassis ng Siklo

Kapag nakikipag-uwian sa produksyon ng siklo, ang katawan ng automotive at chassis ang mga pundasyonal na elemento ng anumang kotse. Kinakailangang mababa ang timbang ngunit matatag ang mga komponente na ito upang siguraduhin ang pagganap, kaligtasan, at kahusayan sa paggamit ng gasolina ng kotse.

Presyo automotive ginagawa ang mga parte upang tugunan ang mga kumplikadong pangangailangan ng katawan ng siklo at chassis produksyon. Tulad ng mga panel ng pinto, fenders, at chassis frames, madalas ginagawa ang mga ito gamit ang metal stamping services . Ang mga parte ng metal stamping ginawa sa proseso na ito ay hugnayan nang maayos upang tumugma sa mga espesipikasyon ng kotse.

metal stamping services

Halimbawa, ang automotive stamping press ginagamit upang lumikha ng mahalagang mga body panel tulad ng quarter panels , roof panels , at bumpers , na naglilingkod sa parehong estetiko at praktikal na layunin. Kailangang sundin ng mga parte na ito ang mabilis na pamantayan sa lakas, katatagan, at eksaktong sukat.

Bakit Mahalaga ang Presisyon sa Auto Stamping para sa mga Body Panel

Ang presisyon ay pangunahin sa produksyon ng mga body panel. Ang automotive stamping press nagpapahintulot sa mga tagapagtatago na lumikha mga parte ng metal stamping na may eksaktong mga detalye, siguraduhing magkakasunod nang maayos ang mga body panel. Mahalaga ito para sa integridad ng anyo ng kotseng at para sa estetika nito. Gayunpaman, ang katumpakan sa metal stamping automotive siguraduhing gumawa ng mga parte sa mabilis na pamamaraan nang hindi nawawala ang kalidad.

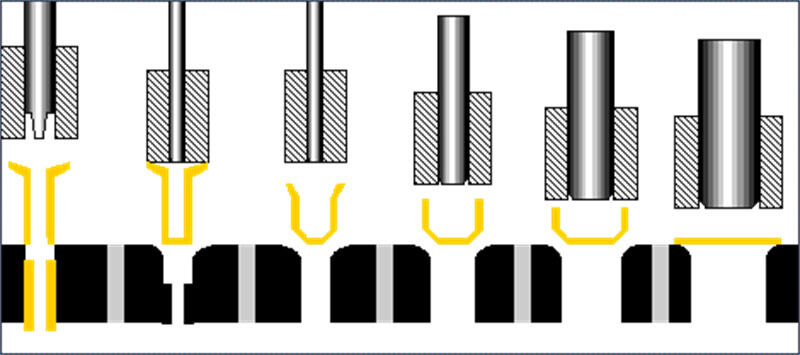

Paggawa ng automotive stamping

Mga Pagganap ng Metal Stamping sa Produksyon ng Katawan ng Kotseng

Isa sa mga pangunahing sanhi metal stamping automotive gamit ang mga parte sa produksyon ng katawan ng kotse ay ang kakayahan ng makabuo ng mataas na presisong komponente sa mabilis na rate. Mga tagapagtatago ng mga bahaging pampresisyon gamit ang advanced automotive stamping press makinang gumagawa ng mga parte na may konsistente na kalidad, na mahalaga sa produksyon ng masaklaw na sasakyan.

Sa dagdag pa, mga parte ng metal stamping nag-aalok ng kinakailangang lakas habang pinapayat ang kabuuan ng timbang ng sasakyan. Ang balanse na ito ay mahalaga para mapabuti ang paggamit ng gasolina at makamtan ang mga estandar ng kapaligiran. Advanced automotive stamping press makinang nagpapahintulot sa mga tagapagtatago na gumawa ng mga komplikadong anyo, tulad ng kurba o kontiado na ibabaw, na may mataas na presisyon at maliit na basura.

Mabilis na produksyon ng metal stamping dies

Kosteng-Bilis na Masaklaw na Produksyon gamit ang Metal Stamping

Metal stamping services nagbibigay ng isang epektibong pamamaraan para gumawa ng malaking dami ng mga parte nang mabilis at kosteng-bilis. Gamit ang automotive stamping press teknolohiya, maaaring tugunan ng mga tagapagtatago ang mataas na dami ng demand habang pinapanatili ang mataas na kalidad, na mahalaga sa kompetitibong industriya ng automotibo.

Pangunahing Komponente na Ginawa sa pamamagitan ng Metal Stamping sa Vehicle Chassis

Sa produksyon ng karsada ng kotse , presyo automotive ginagamit ang mga bahagi upang lumikha ng mga pangunahing komponente tulad ng cross members, subframes, at suspension mounts. Kritikal ang mga bahaging ito para sa kabuuan ng lakas at katigasan ng sasakyan.

Metal stamping services tulong mga tagapagtatago ng mga bahaging pampresisyon nag-aani ng malaking dami ng mga bahaging may presisyon na kinakailangan para sa mga sistema ng karsada. Tulad ng mga komponenteng chassis rails at floor pans ay madalas na ginagawa gamit ang mga parte ng metal stamping dahil sa kanilang mga pangangailangan ng mataas na lakas at ang pangangailangan ng mura at masangsang paggawa.

Ang Papel ng Presisyon sa mga Komponente ng Karsada

Kapag nagpaproduko chassis sa mga komponente, mahalaga na ang mga parte ay presisyo at matatag. Ang automotive stamping press teknolohiya ay nagpapahintulot metal stamping automotive sa mga parte upang sundin ang mabigat na mga espesipikasyon na kinakailangan para sa mga estruktural na komponente. Ito ay nagpapatibay ng kabuuan ng lakas at kaligtasan ng sasakyan, gagawing isang mahalagang aspeto ng proseso ng paggawa ng chasis.

Bakit Magpili ng Metal Stamping Services para sa Paggawa ng Automotive?

Para sa mga tagapagtatago ng mga bahaging pampresisyon , alay metal stamping services para sa paggawa ng automotive ay nagdadala ng maraming mga benepisyo. Una at pangunahin, metal Stamping ay isang napakahusay na paraan para gumawa ng malaking dami ng mga parte nang mabilis. Ito ay tumutulong sa mga gumagawa ng automotive na sundin ang maigting na mga schedule ng produksyon habang pinapanatili ang mataas na pamantayan ng kalidad.

Dahil pati na rin, ang advanced na automotive stamping press teknolohiya ay nagpapatakbo ng produksyon ng mataas na kalidad na mga parte na may minimong mga defektibo. Ito ay kailangan sa industriya ng automotive, kung saan ang mga komponente ay dapat sundin ang mabigat na mga pamantayan ng kaligtasan at regulasyon. Metal stamping services pati na din ito ay bumababa sa mga gastos ng produksyon habang pinapanatili ang kalidad, nagbibigay-daan sa mga gumagawa na manatiling kompetitibo.

Kostohan at Epektibong Gamit ng Oras sa Paggawa ng Automotive

Sa pamamagitan ng paggamit metal stamping automotive teknolohiya, mga tagapagtatago ng mga bahaging pampresisyon maaaring maabot ang malaking mga savings sa oras at gastos sa produksyon ng mga parte ng automotive. Sa anomang sitwasyon na ito para sa katawan ng siklo o chassis mga komponente, mga parte ng metal stamping nagbibigay ng isang tiyak at epektibong solusyon na nakakatugon sa mataas na pamantayan ng industriya ng automotive.

Kulopsis: Ang Kinabukasan ng Metal Stamping sa Paggawa ng Automotive

Habang umuunlad ang industriya ng automotive, ang demand para sa mataas na pagganap metal stamping automotive mga parte ay patuloy na lumalago. Ang pag-unlad ng automotive stamping press teknolohiya ay magpapahintulot mga tagapagtatago ng mga bahaging pampresisyon na gumawa ng higit na kumplikadong, mataas na lakas na mga komponente sa mas mababang gastos. Sa anomang sitwasyon para sa katawan ng siklo o chassis , mga parte ng metal stamping mananatiling kritikal sa paggawa ng automotive.

Habang umuukol ang industriya patungo sa mas sustentableng at mas magaan na mga sasakyan, metal stamping services lalaro ang isang lalong makahulugang papel sa pagsasagot sa mga ito demanda. Sa pamamagitan ng pagbibigay ng makabagong solusyon at mataas na kalidad ng produksyon, metal Stamping patuloy na aangat ang kinabukasan ng paggawa ng automotibol.