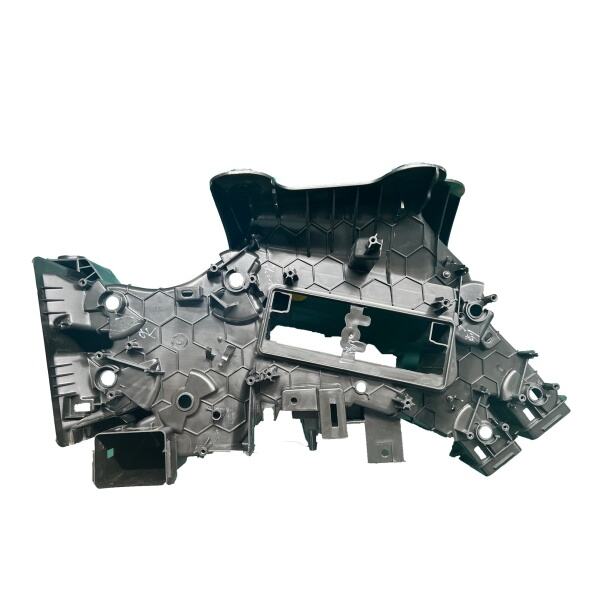

Salom! Iltimos, davom etib o'qying va biz plastikdan qanday mashina qismlarini ishlab chiqaramiz haqida kamchiya-kam fikr oling. Ushbu jarayon plastik shablon yasash deb ataladi. Ammo bu juda ham zanoqdir, chunki Shaoyi avtomobil qaloplari plastikni ichki temperaturaga qadar issiq qiladi, uni shakllantirish imkoniyatiga ega bo'lguncha, keyin esa mashinalarga tegishli qismlarga aylantiradi. Mashina qismlari yuzlar sonida elementlardan iborat bo'lib, bugungi kunda plastik shablon yasash orqali ulardan biri ishlab chiqarilmoqda.

Shuningdek, plastik injektsiya shakllashni tafsilotlarga o'tamiz, bu aslida nimaga oid? Bu, qaynatilgan plastikdan shablon yaratish usuli. Shablon esa plastik materialning foydalaniladigan shaklini qabul qiluvchi maxsus turli qab turi. Buni biz qaynatilgan plastikni shablonda to'xtatib, sochirganimizda amalga oshiramiz. Plastik sochqandan keyin qatorga kiradi va mashina qismi sifatida qayta ishlatilishi mumkin bo'ladi. Ushbu usul mashina qismlari yaratish uchun yaxshi va bir necha soat ichida tezroq va oddiyroq amalga oshirilishi mumkin!

Ammo masalan, biz avtomobil qismlari ishlab chiqarsak, avtomobilning elementlari to'g'ri joylashtirilishi juda muhim. Agar DFD elementlarning biri katta bo'lsa, ikkinchisi esa unda o'rinish uchun ko'proq yoki kichik bo'ladi. Demak, biz super aniqlikka ega bo'lishimiz kerak! Har bir shablon, ishlab chiqilganida, har doim ulardagi talablarga mos kelishi lozim. Ushbu jarayon oddiy emas, lekin Shaoyi-da biz har doim bunga yetarlicha resurslar va odamlar mavjud. Biz har bir elementni, puzlning qismlari kabi, to'g'ri joyiga yetkazishga ishonch saqlaymiz!

Plastik shablon yasash texnologiyasi, dunyo buyicha boshqa hammasi kabi, rivojlanaishi va ishlab chiqarish jarayoni. O'yinchoqlar/yunalishlar kabi, u yangi mahsulotlar har kuni ishlab chiqarilib, davomida turib maydonga chiqariladi. Katta darajada dokumentlangan bayonlar borki, mashinalarimiz har kuni aqlliqlari oshib bormoqda. Shu sababli, Shaoyi-da biz Shaoyi ni sinab ko'ramiz va tozalaymiz avtomobil qiyinchalari . Biz eng yaxshi jarayon va mahsulot materialidan foydalanamiz, bu esa bizga sifatli va xavfsiz qismlarni qurmoq imkonini beradi.

Avtomobil qismlarini dizayn qilishda plastik muammolar orqali yanada murakkab bo'lishi mumkin. Bu ishni bajarish jarayonida o'tishimiz kerak bo'ladigan eng yaxshilar to'plami bo'lishi mumkin. Shuningdek, plastikni shablonga tushirilgandan oldin uni aniqlangan haroratda bo'lishiga ko'ra kelishimiz kerak. Ammo agar suv juda issiq yoki juda sovuq bo'lsa, bu amal qilmasligi mumkin. Shablonning ichidagi havo charchaklarini ham kuzatishimiz kerak, chunki ular keyingi bosqichlarda muammolarga sabab bo'ladi. Lekin unutmang! Musobaqada uchrashgan chetlab ketishlardan Shaoyi tomonidan muammolarni hal qilishda tajriba bilan e'lonlangan professional senior komanda mavjud. Umuman olganda, muammolarni birgalikda hal qilish va hamma narsani imkoniyatiga qarab yaxshi davom ettirishga doir shartnomaga qat'ilangan.

Qulay, plastik shablon yasashning avtomobillar uchun eng yaxshi qismlarni ishlab chiqish usuli ekanligiga ko'ra bo'lmasa ham, bizning holatimizda savol nima. Eng yaxshi qismi esa, barcha kofe sihrining bor yo'li, barcha murakkab ishlardan so'ng sodir bo'lganidir. Va biz avtomobillar uchun qismlarni qurib chiqganimizda, ular bir-biriga to'g'ri ravishda joylashadi. Shaoyi avtomobil qismlari shabloni mashinani kutilgan tarzda ishlatishga yetkazadi va uning ichida turuvchi barcha odamlarni ishlatish jarayonida himoyalaydi.

Kampaniyamiz avtomobil yaratish sohasida mutaxassislik ko'rsatadi, mahsulotlarimizning 90 foizi yuqoricha avtomobil savdo sohasiga qaraganda mustaqil. Biz yetakchi mashinalar, tijoratga mo'ljallangan transport vositalari, golf kartalari hamda mototsiklalar, kamaz va traktorlar kabi turli xil transport vositalari uchun yuqori sifatli komponentlarni ta'minlaymiz. Ushbu keng mahsulot portfelimiz bizning ko'p asosiy avtomobillar bozorining muhtasari talablari bilan urinishga doir ishlab chiqarish va qadrlashimizni tasvirlaydi. Shuningdek, biz Volkswagen uchun suspensiyalar sistemasi yetkazib beruvchilar orasida birinchi sifatda Oʻzbekistonda ishlab chiqarish imkoniyatimizni ko'rsatadi - bu asosiy avtomobillar brendlari uchun ishonchli va inkar qilinmaydigan yechimlarni taklif etish imkoniyatimizni ko'rsatadi. Bizning keng sanoat tajribamiz mahsulotlarimizni faqat mijozlar tomonidan kutub bo'lmagan bajarish va sifatni oshiradi.

IATF sertifikat 16949 ni egallash uchun juda ham guruh bo‘lamiz, bu avtomobil savdoida yetakchi sifat muvofaqiyati biznesimizda qo’llab-quvvatlashga harakat qilayotganimizni isbotlaydi. Sifat bo‘limimiz avtomobil savdosi ichida besh asosiy sifat asboblaridan foydalanishda mahoratga erishgan: Statistik Protsess Nazorati (SPC), O'lchov Tizimlari Analitikasi (MSA), Xato rejimi va ta'sir analitikasi (FMEA), Muvofiqlashtirilgan Mahsulot Sifati Rejalashtirish va Ishlab Chiqarish Qismi Tasdiqlash Protsessi. Shuningdek, sifat xodimlarimiz Six Sigma ta'limiga keng tarqalgan ta’lim oldilar, bu esa bizning mahsulotlar sifati uchun eng shiddatli standartlarga amal qilishimizni ta’minlaydi. Bu to'liq sifat nazorati usuli, bizning har bir mahsulotimiz noto‘g‘ri faqat savdo kutubxonalarini belgilashdan o'tadi balki shuningdek savdo kutubxonalarini yuqoriga ko'taradi va xizmatlarimiz bo'yicha mijozlarimizga ishonch va qanoatlantirishni taqdim etadi.

Avtomobil sektorida 15 yildan ko'p tajribaga ega bo'lgan kompaniya, 10,000 kvadrat metrdan oshib ketadigan maydonni qamrab oladi va 30 dan ortiq avtomobil brendlari uchun metall hissalarini ishlab chiqarishda mutaxassislik egallaydi. Har bir mahsulotning eng yuqori sifat standartlariga erishishi uchun mashinadan otish, CNC mashinasi orqali mashina uskunasining ishlab chiqarilishi, shablon yaratish va aluminium shablonidan litargicheskoe leypish kabi asosiy ishlangan davom etuvchi texnologiyalardan foydalanamiz. Bizning muhim sifatni nazorat jarayonimiz mahsulotlarimizning o'lcham, shakl, surat va ishlayishi jihatidan doimiy ekanligiga ishonch beradi. Bu esa mijozlarimiz bilan ishonch va ishonchni yaratadi.

Biz, har bir inzhenerining avtomobillik sohasida 10 yildan ko'p tajribaga ega bo'lgan mustaqil I+R bo'limimizdan gurur bildiramiz. Ushbu ekspertizalar bizga turli materiallarning xususiyatlari va protsesslarini tushunishga va mijozlarimiz uchun yechimlarni shakllantirishga imkon beradi. Biz professional CAE analizini, maxsulotni rivojlantirishni va texnik yordamni taqdim etamiz, shuningdek dizayning ishlab chiqarish uchun optimallashtirilgan bo'lishiga ishonch hosil qilish uchun to'liq DFM hisobotlarini ham taqdim etamiz. Biz texnikani rivojlantirishga va mijozlarimizning maxsus talablariga javob beradigan yuqori sifatli metall hissalarini taqdim etishga mo'ljallanganmiz.