Avtomobil damgachiligi avtomobillarni yasash dunyosida muhim jarayon. Ushbu jarayon avtomobilning turli qismlariga nisbatan muhim. Shaoyi avtomobil damgachilik korxonasi. Ular avtomobillar uchun shikastlash qismi qism-qismiga mos keladigan va yaxshi ishlaydigan mashinalar uchun maxsus texnikaga va tajribaga ega. Shuning uchun, avtomobil damgachiligini va uning qanday ishlashini yaxshiroq ko'ramiz. Avtomobil damgachiligi metal platalardan avtomobil qismlarini yaratish uchun ishlab chiqaruvchi yetakchilik jarayoni. Bunday qismlar ergashlikdan kapotlarga va burdullarlarga qadar bo'ladi. Barcha boshlanish nuqtasi metal platalaridan iborat, keyin ular katta mashina deb ataladigan damgachilik pressiga o'tkaziladi. Ushbu mashina super kuchli va 'damga' va 'boshqaruv' deb ataladigan murakkab texnikani ishlatadi. Damga va boshqaruv metallarni avtomobilda talab qilinadigan to'g'ri komponentga oyirib, shakllantiradi. Bu, metallar platalaridan foydalanib, ularga 'bosib' avtomobilni qurish uchun qismlarni hosil qilishni o'z ichiga oladi.

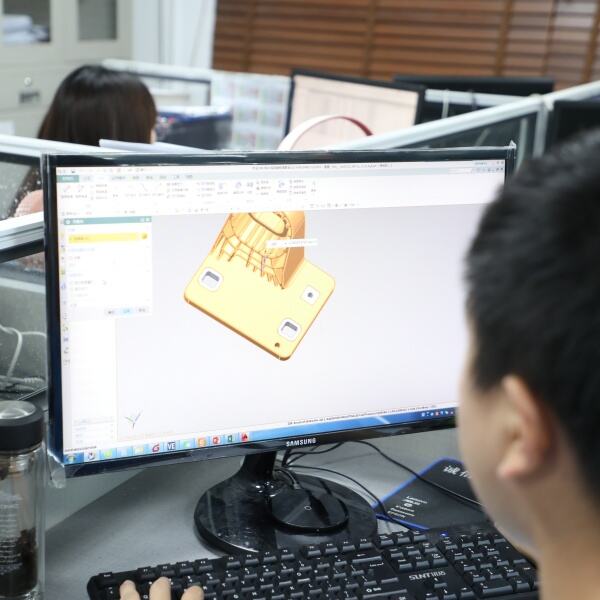

Avtomobil uchun chiziqish texnologiyasi mashinaning ishlab chiqarilishida muhim qismdir, chunki hamma qismlari qisqa vaqtda ishlab chiqarilishi mumkin. Masalan, Shaoyi kompaniyasi tez vaqt ichida bir necha mingta avto qismini ishlab chiqaruvchi chiziqish mashinalariga ega. Ushbu tezlik maxsus, chunki avtomobil savdo sohasi juda shiddatli. Shu avtomobil qismlari damgachiligi avtomobil konstruktorlari, mashinani tezroq qurib chiqsalar, mahsulotni xaridorlarga tezroq yetkazish imkoniyatiga ega bo'ladi. Bu, avtomobillar uchun so'rayotgan talabga amal qilish va komponentlar yetarlicha sonda bo'lishi sababli mashinalarni qurishdagi muammolardan xalos bo'lish imkonini beradi. Avtomobil stamplashish jarayoni hozirgi kunda texnologiyadan foydalanib yangi ko'rinishga kelgan. Shaoyi mashina qismlarini dastlabki kompyuter dasturi orqali dizayn qiladi. Ushbu dastur stamplashish mashinalari bilan ishlaydigan vositalarni yaratadi. Shaoyi ushbu barcha texnologiyalar orqali mijozlariga aniqlikka erishgan va aniq qismlarni taqdim etishi mumkin. Bu, har bir qismning mashina boshqa qismlari bilan mos ravishda tartiblanganligiga ham ishonch beradi. Stamplashish mashinalari esa yangi texnologiyalar asosida ishlaydi va har bir mahsulot o'lcham va standartlarga mos keladi. Ushbu texnologiya muhimdir, chunki u xatoliklardan oldini oladi va barcha qismlarning standartlarga moslashini ta'minlaydi.

Икки йил олдин, мен барча китобларимни таҳрирлаш жараёнига ўтишда, натижага қолиб, салохиятли ривоят қилишда Драфтдан Эдитга қайта-қайта ўтишнинг нечта тезроқ бўладигин топдим. Агар сиз мураккаб драфт язиб борсангиз, удаликда камида хатоликлар бўлади damgachiligi avtomobil qismlari йиғитликлари шу жумладан чекланади ва бunga қарамасдан бир necha мавзуларда асосий натижани тушунгач гиёхонга кўп вақт сарф этиш мумкин — камчиликлардан туриб, у mening тажрибамда бир неча маротабада ўзгаришлар кўрсатган!

Автомобил стампалаши процесси босқичда тез ва андишлайдigan точностьга эга бўлиши керак. Уларда тез стампа машиналари бор ва улар қисқа вақт ичида бир неча бутунликларга эга бўлади. Нихоёш, уларning машиналари такама материални бозмайди ва стампа процессида коп материални бозмайди. Ушбу эффективlik экологик ва компания учун пул сифатидан фойдаланади. Шунингdek, импресия машиналари точностьга эга бўлиши лозим, аks holda бутунликлар сифати қанча да бошқа бўлади. Улар avtomobillar uchun metall shikastlash qismlari keyingi bosqichda Shaoyi tomonidan maxsus sensorlar va boshqaruvidan o'tkaziladi, ularning o'lcham va shakli to'g'ri bo'lishini tekshirish uchun. Bu ishlab chiqarishning har bir qismini speksiya bo'yicha amalga oshirilganligiga va kiyin sertifikatiga erishganligiga ishonch hosil qiladi.

Avtomobil damgachiligi - bu sifatni birinchiliga qo'yadigan protsess. Barcha narsada, Shaoyi xodimlari damgachilik jarayonining sifat yuqorisi chegarasida davom etishi kerakligini ta'minlashga muvaffaq bo'lishini istamoqda. Ular avtomobil metall plitalarini stamping qism-qismga bo'lgan tekshiruv jarayonlari orqali, qismlarning avtomobillarga qo'llab-quvvatlanish uchun yetarlicha sifatli ekanligiga ishonch hosil qiladi. Bu tekshiruvlar ishchiqlarning qismlarni ko'rib chiqishiga va ko'rish mumkin bo'lgan muammolarni aniqlashiga olib kelishi mumkin. Shuningdek, ularga o'lchovni tekshirish ham kiradi, chunki to'g'ri o'lcham bo'lishi lozim. Shuningdek, materialni sinab ko'rish amaliyoti ham amalga oshiriladi, chunki qandaydir metal taniladi - juda qo'lga va murakkab. Bunday sifatni tekshirish orqali, Shaoyi o'zida ishlab chiqarilgan qismlarning sifati va ishonchli bo'lishiga ishonib turadi, va ular mashinalarda ishlatish uchun mo'ljallangan.

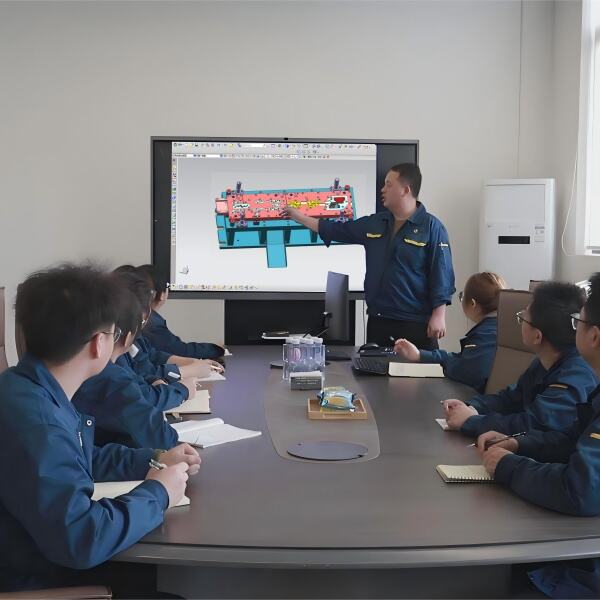

IATF sertifikat 16949 ni egallash uchun juda ham guruh bo‘lamiz, bu avtomobil savdoida yetakchi sifat muvofaqiyati biznesimizda qo’llab-quvvatlashga harakat qilayotganimizni isbotlaydi. Sifat bo‘limimiz avtomobil savdosi ichida besh asosiy sifat asboblaridan foydalanishda mahoratga erishgan: Statistik Protsess Nazorati (SPC), O'lchov Tizimlari Analitikasi (MSA), Xato rejimi va ta'sir analitikasi (FMEA), Muvofiqlashtirilgan Mahsulot Sifati Rejalashtirish va Ishlab Chiqarish Qismi Tasdiqlash Protsessi. Shuningdek, sifat xodimlarimiz Six Sigma ta'limiga keng tarqalgan ta’lim oldilar, bu esa bizning mahsulotlar sifati uchun eng shiddatli standartlarga amal qilishimizni ta’minlaydi. Bu to'liq sifat nazorati usuli, bizning har bir mahsulotimiz noto‘g‘ri faqat savdo kutubxonalarini belgilashdan o'tadi balki shuningdek savdo kutubxonalarini yuqoriga ko'taradi va xizmatlarimiz bo'yicha mijozlarimizga ishonch va qanoatlantirishni taqdim etadi.

Bizning ishlab chiqaradigan mahsulotlarining 90%idan ko'proq avtomobil sanoatiga mo'qil. Keng tarqalgan transport vositalari uchun, shu jumladan yurakchi avtomobillar, golf kartalari, tijoratga mo'qil avtomobillar, mototsikllar, kamaz va traktorlar uchun qabul qilinadigan yuqori sifatli qismlarni taklif etamiz. Bizning keng ashyo mahsulotlarimiz avtomobillar uchun bozordagi barcha talablarini qanoatlantirish imkoniyatimizga shahadatdir. Volkswagen uchun Xitoyda suspensiyalar sistemasi yetakchi ta'minotchisi bo'lib turish bizga mustaqil va inkasatorlik yechimlarni yetakchi avtomobillar brendlari uchun taqdim etish imkoniyatimizni ko'rsatadi. Bizning uzun muddatli sanoat bilimi mahsulotlarimiz faqat mijozlar tomonidan kutub bo'lmagan balki sifat va performans bo'yicha ularga oshirib beradi.

Biz, har bir inzhenerining avtomobillarda 10 yildan ko'p tajribaga ega bo'lgan mustaqil I+R bo'limimizdan juda gururdamiz. Ushbu bilim bizga turli materiallarning xususiyatlari va jarayonlarini tushunishga va mijozlarimizga shaxsiy yechimlarni taklif etishga imkon beradi. Biz professional CAE analizini, maxsulotni rivojlantirishni va texnik yordamni taqdim etamiz, shuningdek, dizaynning har bir tomonining ishlab chiqish talablari bo'yicha rivojlantirilganligiga ishonch hosil qilish uchun to'liq DFM hisobotini ham taqdim etamiz. Biz innovatsiyaga qaratib boramiz va mijozlarimizning aniqlik talablariga mos keladigan eng yuqori sifatdagi metall maxsulotlarini taqdim etamiz.

Yorug‘likdan foydalanuvchi kompaniya, 10,000 kvadrat metrni tashkil qiladigan va 30 dan ortiq avtomobillar brendlari uchun metallik qismlar ishlab chiqarishga oid, biznesda 15 yildan ko‘p tajriba egasida. Biz stantsioner, CNC mashinada mashina maching, shablon ishlab chiqarish va litsey tuzish kabi eng so‘nggi jarayonlardan foydalanamiz, har bir mahsulotni eng yuqori sifat standartlariga yetkazish uchun. Bizning muhim sifat nazorati jarayonlari arxali, hajm va shakllarda, hamda performansda bir xil bo‘lishini ta’minlaymiz. Barchasi hamda mijozlarimiz orasida ishonch va qanoatlantirishni yaratadi.