Bir xil maxsus usul bo'yicha metall asboblarini ishlab chiqarishni taqdim etishimizdan xursandmiz, bu usul progressiv olib borish damgasi deb ataladi. Bu texnologiya juda tez va juda aniqlikka erishuvchi metall asboblarini yaratadi, va vaqt va pulni saqlaydi. Progressiv Olib Borish Damgasi: Uzun metall tirasining seriyasi orqali o'tkazilishi kerak, ular damgalar deb ataladi. Ular metallni bizga kerak bo'lgan qismlarga damgalaydi va formatlaydi. Metall tira safarida Shaoyi avtomobil tubi jarayon bir necha marta takrorlanadi, va uni davom etmasdan bajardikdan so'ng, biz kerakli barcha alohida qismlarni ishlab chiqarishimiz mumkin. Barcha ularning oldindan maqul bo'lgan jihatlari, pasreysiv shablon orqali bosishni turli xil turdagi ko'p turdagi ishlab chiqarish vazifalari uchun mustaqil tanlov qilishga imkon beradi.

Oldindan davom etuvchi matritsa damgachiligi o'zining qarshisida cheklangan qulayliklarga ega, shu jumladan komponentlarni ishlab chiqarish tezligi va oddiylik. Aksariyat holda, oldindan davom etuvchi matritsa damgachiligi esa har bir qismni bir-biriga (bu ko'p vaqt olishi mumkin) emas, balki bir nechta qismlar bir vaqtda ishlab chiqariladi. Bu, ishlab chiqarish muddatlarini qisqartirish va barcha jarayonlarda ko'proq effektivlikka olib keladi. Bu, vaqtni kamaytirish va atlosh materialni kamaytirishga olib keladi, chunki metall siklidan to'la foydalaniladi va undan juda az qancha tashlanadi. Ushbu metall siklining optimallashtirilishi orqali ishlab chiqaruvchilar qoldiq materiallardan foydalanmaslikni kamaytirishlari mumkin, bu ishlatilmagan qoldiq materiallardir. Bu resurslarni saqlashda va jarayonning ekologik bo'lish darajasini oshirishda xususi hissa o'ynaydi.

Shuningdek, oldindan davom etuvchi matritsa damgachiligi hamda juda flexibel. Bu usul ancha turdagi metall qismlarni, oddiy shakllardan boshlab, ko'proq murakkab shakllarga qadar ishlab chiqarish uchun muhimdir. Bu Shaoyi avtomobillar uchun alüminiy boshqacha sanoq, har bir sanoat o'z maxsus talablariga ega. Usul shuningdek turli dizayn talablari uchun aniq sozlana oladi – masalan, metallning toqirligi yoki material turi farqlanishi mumkin. Protsess kompaniya kerak bo'lgan har bir qism uchun optimallashtirilishi mumkin, masalan, mashina uchun engACHQ qism uchun. Shuning uchun, qadamiy daraja bosish xususan avtomobil, elektronika va kosmos sanoati kabi sanoatlarda juda aniqlik va sozlanish imkoniyati bilan birgalikda muhim.

Bu yerda progresiv shablon orqali pulingiz uchun ko'p saqlash foydalaridan gap. Ushbu jarayon eskisi shablon usullaridan arzonroq, chunki vaqtinchalik tartibda ishlab chiqariladi va kam material ishlatadi. Agar ishlab chiqaruvchi tez va yuqori aniqlik bilan qismlarni ishlab chiqarsa, ular ham masaln, asosiy mahsulotlar va kuchiga ko'proq sarf etmaydi. Shuningdek, progresiv shablon orqali juda muvofiq natija olinadi, ya'ni har bir qism bir xil tarzda ishlab chiqariladi. Bu esa kamroq qayta ishlash yoki almashtirishlarga — katta saqlashga olib keladi. Xatolarni to'g'irlash yoki buzilgan qismlarni almashtirishdan imtinoz qilish orqali korxonalarning pulini katta miqdorda saqlashiga imkon beradi va bu amal holatda butunlay, effektiv jarayon bo'ladi.

Progresiv shablon orqali dam olish doim muhim ishlab chiqarish materiali bo'lib kelgan va dunyo o'zgaruvchan ishlab chiqarish dunyosiga yo'naltirilishi bilan uni talabi ko'paymoqda. Shaoyi metallni maxsus bosish matolari protsess ekstremalno effektiv, tez va iqtisodiydir, shuningdek, hozirda ko'p talab qilinadigan klassik ishlab chiqarish usullaridan bir nechta foydalar bilan. Shaoyi muvaffaqiyatli progressiv olib borish damgasi mahsulotini taqdim etishga harakat qiladi va buyuk darajada mustaqillikka erishgan sifatda mustahkamlashadi. Yana yangi sohalarga kirishimizda ishlab chiqarish va metallarda yengil innovatsiyaga sayog'lik qilamiz.

Kampaniyamiz, avtomobil sanoatida oʻrtacha on yildan koʻp tajriba egasi muhandislardan iborat mustaqil I+R jamoasiga ega boʻlishda guruhlangan. Ushbu tajriba bizga turli xil uslublar va materiallardagi unikal xususiyatlarni tushunishga va mijozlarimiz uchun moyinlashtirilgan yechimlarni taqdim etishga imkon beradi. Biz CAE analizini, rivojlantirishni va texnik yordamni taqdim etamiz, shuningdek, dizaynning har bir tomonining ishlab chiqish uchun optimallashtirilganligiga ishonch hosil qilish uchun komprehenziv DFM hisobotlarini ham taqdim etamiz. Biz innovatsiya bilan shugullanamiz va mijozlarimiz talablariga javob beradigan yuqori sifatli metall hissalarini yetkazib beramiz.

Bizning ishlab chiqaradigan mahsulotlarining 90%idan ko'proq avtomobil sanoatiga mo'qil. Keng tarqalgan transport vositalari uchun, shu jumladan yurakchi avtomobillar, golf kartalari, tijoratga mo'qil avtomobillar, mototsikllar, kamaz va traktorlar uchun qabul qilinadigan yuqori sifatli qismlarni taklif etamiz. Bizning keng ashyo mahsulotlarimiz avtomobillar uchun bozordagi barcha talablarini qanoatlantirish imkoniyatimizga shahadatdir. Volkswagen uchun Xitoyda suspensiyalar sistemasi yetakchi ta'minotchisi bo'lib turish bizga mustaqil va inkasatorlik yechimlarni yetakchi avtomobillar brendlari uchun taqdim etish imkoniyatimizni ko'rsatadi. Bizning uzun muddatli sanoat bilimi mahsulotlarimiz faqat mijozlar tomonidan kutub bo'lmagan balki sifat va performans bo'yicha ularga oshirib beradi.

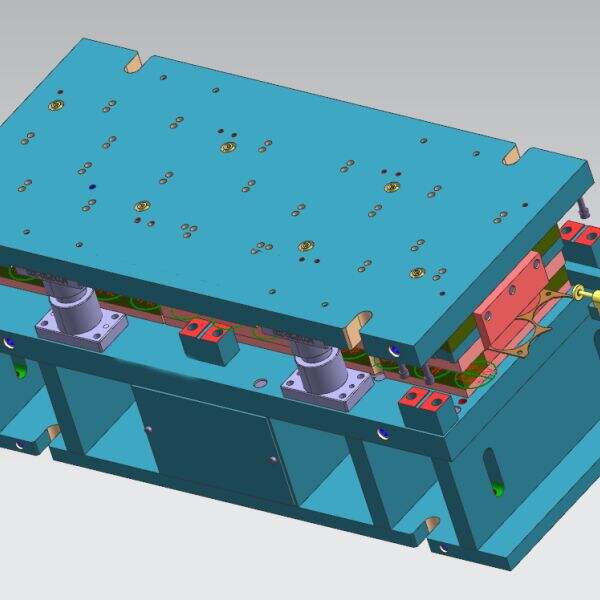

Bizning kompaniya 10,000 kvadrat metr yuza boʻlgan va 30 dan ortiq avtomobil brendlari uchun metall komponentlarni ishlab chiqarishda mutaxassis boʻlib, sanoatda 15 yildan koʻproq tajriba egasi. Biz damqoʻshqich, CNC mashinaviy mashina, shablon ishlab chiqarish va qaytqich usullariga ega boʻlgan eng soʻnggi texnologiyalardan foydalanamiz, har bir mahsulotni eng yuqori sifat standartlariga amal qilish uchun. Bizning muhkim sifat nazorati bizning mahsulotlarimizning hajmi, shakllari va xususiyatlari jihatidan bir xil boʻlishini ta’minlaydi. Bu mijozlarimizning ishonchini va qoniqtirishini oshiradi.

Kamramiz, avtomobil sanoatida sifat boshqaruviga nisbatan qo'lda o'tganimizni isbotlash uchun IATF Sertifikat 16949 egasimanligimizda. Sifat bo'limimiz avtomobil sanoatidagi sifatni oshirishga qaratib, statistik jarayon nazorati (SPC), o'lchov tizimlari analitikasi (MSA), muvaffaqiyatsizlik rejalarini va ularning ta'sirlarini analiz qilish (FMEA), mahsulotning sifatini oldindan rejalashtirish va ishlab chiqarish jarayonining tasdiqlash jarayoniga oid besh asosiy sifat asboblarini bilib olgan. Shuningdek, sifat xodimlarimiz intenziv Olt Sigma ta'limidan o'tkazilgan va biz mahsulotning sifati standartlariga mos kelishiga eng muhim standartlarga amal qilamiz. Bu to'liq sifat boshqaruvi tizimi, bizning har bir mahsulotimiz faqat sanoat talablariga javob beradi balki shuni oshiradi hamda mijozlarimizga xizmatlardan ko'p qadrlashganligini va rahmatlarni ta'minlaydi.