Qanday Avtomobil Shablon Qismlari Jism va Chasis Yetkazishida Foydalaniladi

Avtomobil ishlab chiqarish sanoatida, metallni bosish avtomobil qismlar avtomobillar uchun asosiy komponentlarni ishlab chiqarishda muhim hissa oynaydi. Jarayon shablonlash usuli orqali ishlab chiqilgan avtomobillar qismlari metall plastriga bosim qo'yish orqali unga kerakli ko'rinishni berishga toxri joy. Ushbu jarayon, transport vositalarining konstruktiv egalligi, xavfsizlik va umumiy bajarimcha sifatiga ko'rib chiqadigan komponentlarni ishlab chiqarishda muhim hissa oynaydi. Ushbu maqolada biz qandaydir avtomobil stamplashish pressi texnologiyasi qanday ishlatilishi haqida gapiraman transport vositasining korpusi va shassi komponentlari.

Avto stamplashish qismlari transport vositalari korpusi va shasiya ishlab chiqarishidagi rolidan

Transport vositalari ishlab chiqarishiga doir bo'lganda, avtomobil korpusi va shassi har qanday transport vositasining asosiy elementlari hisoblanadi. Ushbu komponentlar avtomobilning bajarishiga, xavfsizligiga va yonotg‘ich effektivligiga ishonch berish uchun eng kam og‘irlikda, lekin osonroq bo‘lishi kerak.

Shablonlash usuli orqali ishlab chiqilgan avtomobillar kompleks talablarni qanoatlantirish uchun ishlab chiqiladi transport vositasining korpusi va shassi ishlab chiqish. Erkak panel, ilga va shasi qismlari shablonlash usuli orqali umumiy ravishda ishlab chiqiladi metal chiziqish xizmatlari . Oʻzbekiston Respublikasi metall damgachilik qismlari ushbu jarayonda ishlab chiqilgan maxsulotlar transport vositalarning speksiyaiga mos keladigan to‘g‘ri shaklda yasaladi.

metal chiziqish xizmatlari

Masalan, avtomobil stamplashish pressi mashina korpusining asosiy panel larini yaratish uchun ishlatiladi chetor panel , ustki panel , va bumplery , bu esa estetik va funktsional maqsadlarga xizmat qiladi. Ushbu qismlar kuchli, odamsiz va o'lchovlar bo'yicha aniq standartlarni bajarmalilar.

Nasoslashda aniqlik nima uchun muhim avtomobilda jism paneli uchun

Aniqlik jism panelining ishlab chiqarishida asosiy hissada turadi. avtomobil stamplashish pressi ishlab chiqaruvchilarga imkon beradi metall damgachilik qismlari to'g'ri speksifikatsiyalar bilan, jism paneli bir-biriga to'g'ri mos kelishi uchun. Bu aniqlik mashina struktural rostligi va ko'rinishi uchun muhimdir. Shuningdek, aniqlik metallni bosish avtomobil tez ishlab chiqarishni ta'minlaydi, sifatga zarar bermaydi.

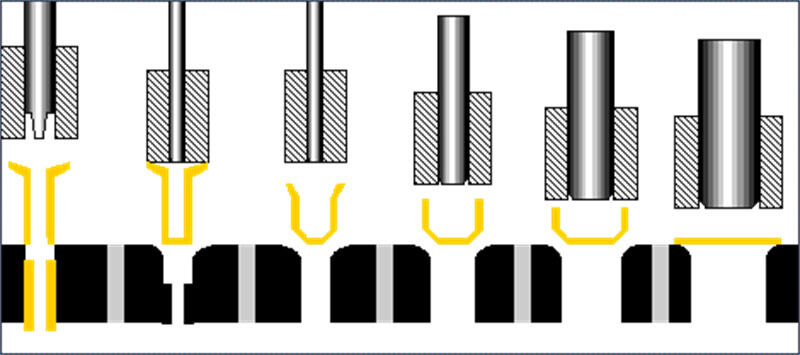

Nasoslash avtomobilda ishlab chiqarish

Metal nasoslashining foydasi mashina jismi ishlab chiqarishida

Asosiy sabab metallni bosish avtomobil qismlari mashina jismi ishlab chiqarishida tez tezlikda aniq komponentlarni ishlab chiqarish imkoniyati. Urinish qismlari ishlab chiqaruvchilari javobgar avtomobil stamplashish pressi mashinalaridan foydalanadi, barcha qismlarni muvofiq sifatda yaratish uchun, bu esa kengayuvchi avtomobillar ishlab chiqarishda asosiy hissa.

Bundan tashqari, metall damgachilik qismlari qisman kerakli quvvatni ta'minlaydi, bir vaqtning o'zida transport vositasining umumiy og'irligini pastga saklaydi. Ushbu balans, yonliqlarning ekologik standartlarga mos kelishini ta'minlash va yanada oshirish uchun muhimdir. Javobgar avtomobil stamplashish pressi mashinalar ishlab chiquvchilarga murakkab shakllarni, masalan, qo'rqin yoki konturi langar yuzlarini, eng kam xatar bilan va yetarlicha aniqlikda ishlab chiqishiga imkon beradi.

Metal chiziqish matritsalarini tez ishlab chiqarish

Metal chiziqish orqali arzon narxli kengayuvchi ishlab chiqarish

Metal chiziqish xizmatlari kengajam qismlarni tez va arzon narxli usulda ishlab chiqarish uchun effektiv usul ko'rsatadi. avtomobil stamplashish pressi texnologiyadan foydalanib, ishlab chiquvchilar kalit sifatni saqlashda muvaffaqiyatga erishishi mumkin, bu esa rekabotlikka ega avtomobil sanoatida asosiy.

Metall urinishi orqali ishlab chiqilgan transport vositasining shasi asosiy qismlari

Ishlab chiqishida transport vositasining shasi , shablonlash usuli orqali ishlab chiqilgan avtomobillar qarama-qarshi a'zolar, pastki ramka va suspensega o'rnatiladigan elementlar kabi konstruktivli asosiy qismlarni yaratish uchun ishlatiladi. Ushbu qismlar transport vositasining umumiy kuchligi va zidlikni ta'minlashda muhim hissa o'ynaydi.

Metal chiziqish xizmatlari yordam urinish qismlari ishlab chiqaruvchilari shasi tizimlari uchun kerak bo'ladigan to'g'ri aniqlikli qismlarning katta hajmdagi ishlab chiqarishini amalga oshiradi. Masalan, shasi relsleri va yerdagi panel ishlab chiqarish uchun tipik ravishda ishlatiladi metall damgachilik qismlari ularning kuchli talablari va arzon narxli massaviy ishlab chiqarish talabiga javob berish uchun.

Tosif qismlarida aniqlikning roli

Ishlab chiqarishda shassi qismlar, qism-qismi aniq va ilojiy bo'lishi kerak. avtomobil stamplashish pressi texnologiya omadli metallni bosish avtomobil qismlar konstruktiv qismlar uchun talab qilinadigan sharoitlarga mos keladi. Bu mashina umumiy kuchligini va xavfsizlikni ta’minlaydi, shuning uchun tosif ishlab chiqarish jarayonida aniqlik muhim aspekt hisoblanadi.

Nega avtomobil ishlab chiqarish uchun metall sur’atlash xizmatlarini tanlash kerak?

Учун urinish qismlari ishlab chiqaruvchilari taklif qilish metal chiziqish xizmatlari avtomobil ishlab chiqarishda ko'p foydalar bor. Birinchi sifatdan, metallni bosish bu usul tez ishlab chiqarish uchun eng effektli usul hisoblanadi. Bu avtomobil ishlab chiqaruvchilari talab qiladigan ishlab chiqarish jadvallarini bajarishga yordam beradi va samarali sifat standartlarini saqlaydi.

Shuningdek, modern avtomobil stamplashish pressi texnologiya minimal defekt bilan yuqori sifatli qismlarni ishlab chiqarishga ta’minkor bo’ladi. Bu avtomobil savdo sohasida, qismlar muhim xavfsizlik va regulirovka standartlariga mos kelishi lozim. Metal chiziqish xizmatlari hamda sifatni saqlash orqali ishlab chiqarish xarajatlarni kamaytiradi, bu esa ishlab chiqaruvchilarga rivojlantirishga imkon beradi.

Avtomobil ishlab chiqarishidagi xarajat va vaqt effektivligi

Foydalanish orqali metallni bosish avtomobil texnologiya urinish qismlari ishlab chiqaruvchilari avtomobil qismlari ishlab chiqarishida vaqt va xarajatlarda muhim taqalluotlarni hosil qilishi mumkin. Bu hammasi uchun transport vositasining korpusi yoki shassi komponentlar metall damgachilik qismlari avtomobil sanoatining yuqori standartlariga mos bo'lgan ishonchli va effektiv bo'lgan yechimni taqdim etadi.

Xulosa: Metal shakllantirishning avtomobil ishlab chiqarishidagi kelajagi

Avtomobil sanoati rivojlanyotganida, yuqori performansli metallni bosish avtomobil qism lar talabi davom etib borishi mumkin. Rivojlantirish avtomobil stamplashish pressi texnologiya imkon qaytaradi urinish qismlari ishlab chiqaruvchilari ko'proq murakkab, yuqori kuchlik komponentlarni pastroq narxlarda ishlab chiqishga. Chegaralangan bo'lsalar ham uchun transport vositasining korpusi yoki shassi , metall damgachilik qismlari avtomobillar asosiy sanoatida muhim bo'lishi kerak.

Sanoat ekologik va eng kam og'irlikdagi transport vositalariga yo'naltirilganligi sababli metal chiziqish xizmatlari ularning talablariga javob berishda ko'proq ahamiyatga ega bo'ladi. Innovatsion yechimlar va sifatli ishlab chiqarishni taqdim etish orqali metallni bosish avtomobil sanoatining kelajagini shakllantirishda davom etadi.