Cómo se utilizan las piezas de estampado automotriz en la producción del cuerpo y chasis del vehículo

En la industria de fabricación automotriz, estampado de metal automotriz las piezas son esenciales para producir componentes clave para los vehículos. El proceso de estampado automotriz piezas implica aplicar presión a una hoja metálica para darle la forma deseada. Este proceso es crucial para fabricar componentes que contribuyen a la integridad estructural, seguridad y rendimiento general del vehículo. En este blog, exploraremos cómo la tecnología de prensa de estampación automotriz se utiliza en la producción de cuerpo del vehículo y chasis componentes.

El papel de las piezas de estampación automotriz en la producción del cuerpo y chasis del vehículo

Cuando se trata de la producción de vehículos, el cuerpo del automóvil y chasis son los elementos fundamentales de cualquier vehículo. Estos componentes deben ser ligeros pero duraderos para garantizar el rendimiento, la seguridad y la eficiencia del combustible del vehículo.

Estampado automotriz partes se producen para cumplir con los requisitos complejos de cuerpo del vehículo y chasis producción. Componentes como paneles de puertas, guardabarros y marcos de chasis se producen comúnmente utilizando servicios de estampado metálico . La piezas de estampado metálico producidos en este proceso están diseñados precisamente para ajustarse a las especificaciones del vehículo.

servicios de estampado metálico

Por ejemplo, el la tecnología de prensa de estampación automotriz se utiliza para crear paneles corporales esenciales como paneles laterales , paneles del techo , y parachoques , que cumplen tanto propósitos estéticos como funcionales. Estas partes deben cumplir con estrictos estándares de resistencia, durabilidad y precisión dimensional.

Por qué la precisión importa en el estampado automotriz para paneles corporales

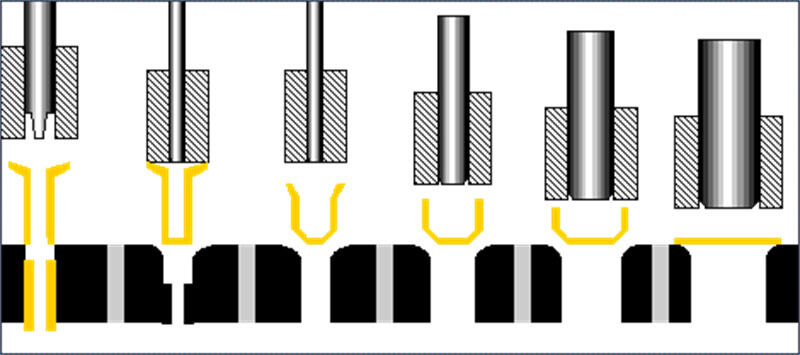

La precisión es clave en la producción de paneles del cuerpo. El la tecnología de prensa de estampación automotriz permite a los fabricantes crear piezas de estampado metálico con especificaciones exactas, asegurando que los paneles del cuerpo encajen perfectamente. Esta precisión es crucial tanto para la integridad estructural como para el atractivo visual del vehículo. Además, la precisión en estampado de metal automotriz asegura que las piezas se produzcan a alta velocidad sin comprometer la calidad.

Fabricación de estampado automotriz

Ventajas del Estampado Metálico en la Producción de Cuerpos de Vehículos

Una de las principales razones estampado de metal automotriz las piezas utilizadas en la producción de cuerpos de vehículos es la capacidad de producir componentes de alta precisión a una velocidad rápida. Fabricantes de piezas estampadas usan avanzados la tecnología de prensa de estampación automotriz máquinas para crear piezas con una calidad consistente, lo cual es esencial para la producción masiva de vehículos.

Además, piezas de estampado metálico ofrecen la resistencia necesaria mientras mantienen bajo el peso total del vehículo. Este equilibrio es crucial para mejorar la eficiencia en el consumo de combustible y cumplir con los estándares ambientales. Avanzado la tecnología de prensa de estampación automotriz máquinas permiten a los fabricantes producir formas complejas, como superficies curvas o contorneadas, con alta precisión y un mínimo de desperdicio.

Producción rápida de matrices de estampado metálico

Producción Masiva Rentable con Estampado Metálico

Servicios de estampado metálico proporcionan un método eficiente para producir grandes cantidades de piezas rápidamente y de manera rentable. Al utilizar la tecnología de prensa de estampación automotriz tecnología, los fabricantes pueden satisfacer demandas de alto volumen mientras mantienen una alta calidad, lo cual es esencial para la competitiva industria automotriz.

Componentes Clave Producidos por Estampado Metálico en el Chasis de Vehículos

En la producción de chasis de vehículo , estampado automotriz las piezas se utilizan para crear componentes estructurales como los miembros transversales, sub Marcos y puntos de montaje de la suspensión. Estas piezas son críticas para garantizar la fuerza y rigidez general del vehículo.

Servicios de estampado metálico ayuda fabricantes de piezas estampadas producen grandes volúmenes de piezas de precisión necesarias para los sistemas de chasis. Componentes como raíles de chasis y paneles del piso se producen típicamente utilizando piezas de estampado metálico debido a sus requisitos de alta resistencia y la necesidad de una producción masiva rentable.

El Papel de la Precisión en los Componentes del Chasis

Al producir chasis componentes, es esencial que las piezas sean tanto precisas como duraderas. El la tecnología de prensa de estampación automotriz tecnología permite estampado de metal automotriz que las piezas cumplan con las estrictas especificaciones requeridas para componentes estructurales. Esto asegura la fuerza y seguridad general del vehículo, haciendo de la precisión un aspecto vital en el proceso de producción del chasis.

¿Por qué Elegir Servicios de Estampado Metálico para la Producción Automotriz?

Para fabricantes de piezas estampadas , ofreciendo servicios de estampado metálico para la producción automotriz ofrece numerosas ventajas. En primer lugar, estampado Metálico es un método altamente eficiente para producir grandes cantidades de piezas rápidamente. Esto ayuda a los fabricantes automotrices a cumplir con los exigentes cronogramas de producción mientras mantienen altos estándares de calidad.

Además, la avanzada la tecnología de prensa de estampación automotriz tecnología garantiza la producción de piezas de alta calidad con mínimos defectos. Esto es esencial en la industria automotriz, donde los componentes deben ajustarse a estrictos estándares de seguridad y regulaciones. Servicios de estampado metálico también reducen los costos de producción mientras mantienen la calidad, permitiendo a los fabricantes permanecer competitivos.

Eficiencia en Costos y Tiempo en la Producción Automotriz

Al utilizar estampado de metal automotriz tecnología, fabricantes de piezas estampadas se pueden lograr ahorros significativos de tiempo y costos en la producción de piezas automotrices. Ya sea para cuerpo del vehículo o chasis componentes, piezas de estampado metálico proporcionan una solución confiable y eficiente que cumple con los altos estándares de la industria automotriz.

Conclusión: El Futuro del Estampado Metálico en la Fabricación Automotriz

A medida que la industria automotriz evoluciona, la demanda de piezas de alto rendimiento estampado de metal automotriz partes seguirá creciendo. El desarrollo de la tecnología de prensa de estampación automotriz tecnología permitirá a fabricantes de piezas estampadas producir componentes más complejos y de alta resistencia a menor costo. Ya sea para cuerpo del vehículo o chasis , piezas de estampado metálico seguirá siendo crucial en la fabricación automotriz.

A medida que la industria se dirige hacia vehículos más sostenibles y ligeros, servicios de estampado metálico desempeñará un papel cada vez más importante para satisfacer estas demandas. Al ofrecer soluciones innovadoras y una producción de alta calidad, estampado Metálico seguirá moldeando el futuro de la fabricación automotriz.