Como Peças Estampadas Automotivas São Utilizadas na Produção de Carrocerias e Chassis de Veículos

No setor de fabricação automotiva, estampagem de metal automotiva peças são essenciais para produzir componentes principais para veículos. O processo de estampagem automotiva peças envolve aplicar pressão a uma chapa metálica para moldá-la na forma desejada. Este processo é crucial para fabricar componentes que contribuem para a integridade estrutural, segurança e desempenho geral do veículo. Neste blog, exploraremos como tecnologia de prensa de estampagem automotiva é usada na produção de carroceria de veículo e chassi componentes.

O Papel das Peças de Estampagem Automotiva na Produção de Carroceria e Chassi de Veículos

Quando se trata de produção de veículos, o corpo do veículo e chassi são os elementos fundamentais de qualquer veículo. Esses componentes devem ser leves, mas duráveis para garantir o desempenho, a segurança e a eficiência no consumo de combustível do veículo.

Estampagem automotiva peças são produzidas para atender aos requisitos complexos de carroceria de veículo e chassi produção. Componentes como painéis de porta, para-lamas e quadros do chassi são comumente produzidos usando serviços de estampagem metálica . O peças de estampagem de metal produzidos neste processo são moldados com precisão para se ajustar às especificações do veículo.

serviços de estampagem metálica

Por exemplo, o tecnologia de prensa de estampagem automotiva é usado para criar painéis corporais essenciais como painéis laterais traseiros , painéis do teto , e para-choques , que servem tanto para fins estéticos quanto funcionais. Essas peças precisam atender a padrões rigorosos de força, durabilidade e precisão dimensional.

Por que a Precisão é Importante na Estampagem Automotiva para Painéis Corporais

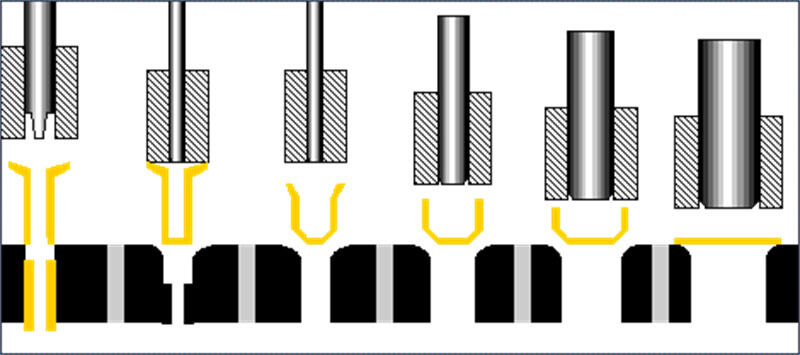

A precisão é fundamental na produção de painéis do corpo. O tecnologia de prensa de estampagem automotiva permite que os fabricantes criem peças de estampagem de metal com especificações exatas, garantindo que os painéis do corpo se encaixem perfeitamente. Essa precisão é crucial tanto para a integridade estrutural quanto para o apelo visual do veículo. Além disso, a precisão em estampagem de metal automotiva garante que as peças sejam produzidas em alta velocidade sem comprometer a qualidade.

Fabricação de peças automotivas estampadas

Vantagens da Estampagem Metálica na Produção de Corpos de Veículos

Um dos principais motivos estampagem de metal automotiva peças são usadas na produção de corpos de veículos é a capacidade de produzir componentes de alta precisão rapidamente. Fabricantes de peças estampadas usam tecnologias avançadas tecnologia de prensa de estampagem automotiva máquinas para criar peças com qualidade consistente, o que é essencial para a produção em massa de veículos.

Além disso, peças de estampagem de metal oferecem a força necessária enquanto mantêm o peso total do veículo baixo. Esse equilíbrio é crucial para melhorar a eficiência no consumo de combustível e atender aos padrões ambientais. Avançado tecnologia de prensa de estampagem automotiva máquinas permitem que fabricantes produzam formas complexas, como superfícies curvas ou contornadas, com alta precisão e mínimo desperdício.

Produção rápida de matrizes de estampagem metálica

Produção em Massa Custosa com Estampagem Metálica

Serviços de estampagem metálica fornecem um método eficiente para produzir grandes quantidades de peças rapidamente e de forma custo-benefício. Ao usar tecnologia de prensa de estampagem automotiva tecnologia, fabricantes podem atender demandas de alto volume enquanto mantêm alta qualidade, o que é essencial para a competitiva indústria automotiva.

Componentes Principais Produzidos por Estampagem Metálica no Chassi do Veículo

Na produção de chassi do veículo , estampagem automotiva peças são usadas para criar componentes estruturais, como membros transversais, subframes e pontos de fixação da suspensão. Essas peças são cruciais para garantir a força e rigidez geral do veículo.

Serviços de estampagem metálica ajuda fabricantes de peças estampadas produzem grandes volumes de peças de precisão necessárias para sistemas de chassi. Componentes como travessas do chassi e partes do piso são normalmente produzidos usando peças de estampagem de metal devido aos seus requisitos de alta resistência e à necessidade de produção em massa custo-efetiva.

O Papel da Precisão nos Componentes do Chassi

Ao produzir chassi componentes, é essencial que as peças sejam tanto precisas quanto duráveis. O tecnologia de prensa de estampagem automotiva tecnologia permite estampagem de metal automotiva peças atendam às especificações rigorosas exigidas para componentes estruturais. Isso garante a força e a segurança geral do veículo, tornando a precisão um aspecto vital do processo de produção do chassi.

Por que Escolher Serviços de Estampagem Metálica para Produção Automotiva?

Para fabricantes de peças estampadas , oferecendo serviços de estampagem metálica para produção automotiva traz numerous vantagens. Antes de tudo, estamparia de metal é um método altamente eficiente para produzir grandes quantidades de peças rapidamente. Isso ajuda os fabricantes automotivos a atenderem a cronogramas de produção exigentes enquanto mantêm altos padrões de qualidade.

Além disso, a avançada tecnologia de prensa de estampagem automotiva tecnologia garante a produção de peças de alta qualidade com defeitos mínimos. Isso é essencial na indústria automotiva, onde os componentes devem seguir rigorosos padrões de segurança e regulamentação. Serviços de estampagem metálica também reduzem custos de produção enquanto mantêm a qualidade, permitindo que os fabricantes permaneçam competitivos.

Eficiência de Custo e Tempo na Produção Automotiva

Ao utilizar estampagem de metal automotiva tecnologia, fabricantes de peças estampadas pode-se alcançar economias significativas de tempo e custo na produção de peças automotivas. Seja para carroceria de veículo ou chassi componentes, peças de estampagem de metal fornecem uma solução confiável e eficiente que atende aos altos padrões da indústria automotiva.

Conclusão: O Futuro do Estampagem de Metal na Fabricação Automotiva

À medida que a indústria automotiva evolui, a demanda por peças de alto desempenho estampagem de metal automotiva partes continuará a crescer. O desenvolvimento da tecnologia de tecnologia de prensa de estampagem automotiva permitirá fabricantes de peças estampadas produzir componentes mais complexos e de alta resistência a custos mais baixos. Seja para carroceria de veículo ou chassi , peças de estampagem de metal continuará sendo crucial na fabricação automotiva.

À medida que a indústria avança para veículos mais sustentáveis e leves, serviços de estampagem metálica terá um papel cada vez mais importante no atendimento a essas demandas. Ao oferecer soluções inovadoras e produção de alta qualidade, estamparia de metal continuará a moldar o futuro da fabricação automotiva.