Cách Các Phụ Tùng Dập Lạnh Ô Tô Được Sử Dụng Trong Sản Xuất Thân Xe Và Khung Gầm

Trong ngành công nghiệp sản xuất ô tô, kim loại đóng dấu ô tô các bộ phận là yếu tố không thể thiếu để sản xuất các thành phần chính cho phương tiện. Quy trình của đột dập ô tô các bộ phận bao gồm việc áp dụng áp lực lên tấm kim loại để định hình nó thành hình dạng mong muốn. Quá trình này rất quan trọng trong việc sản xuất các thành phần góp phần vào độ bền cấu trúc, sự an toàn và hiệu suất tổng thể của phương tiện. Trong bài viết này, chúng ta sẽ khám phá cách công nghệ dập ô tô được sử dụng trong việc sản xuất thân xe và khung gầm thành phần.

Vai trò của các bộ phận dập ô tô trong sản xuất thân xe và khung gầm

Khi nói đến việc sản xuất phương tiện, thân xe ô tô và khung gầm là những yếu tố nền tảng của bất kỳ phương tiện nào. Những thành phần này phải nhẹ nhưng vẫn bền để đảm bảo hiệu suất, an toàn và tiết kiệm nhiên liệu của phương tiện.

Đột dập ô tô phần được sản xuất để đáp ứng các yêu cầu phức tạp của thân xe và khung gầm sản xuất. Các bộ phận như tấm cửa, cánh lướt gió và khung gầm thường được sản xuất bằng cách sử dụng dịch vụ dập kim loại . Dòng các bộ phận đúc kim loại được sản xuất trong quy trình này có hình dạng chính xác theo thông số kỹ thuật của phương tiện.

dịch vụ dập kim loại

Ví dụ: công nghệ dập ô tô được sử dụng để tạo ra các tấm thân xe quan trọng như tấm góc , tấm mái , và cản bumpers , phục vụ cả mục đích thẩm mỹ và chức năng. Những bộ phận này cần đáp ứng các tiêu chuẩn nghiêm ngặt về độ mạnh, độ bền và độ chính xác kích thước.

Tại sao sự chính xác lại quan trọng trong việc dập thân xe cho các tấm thân

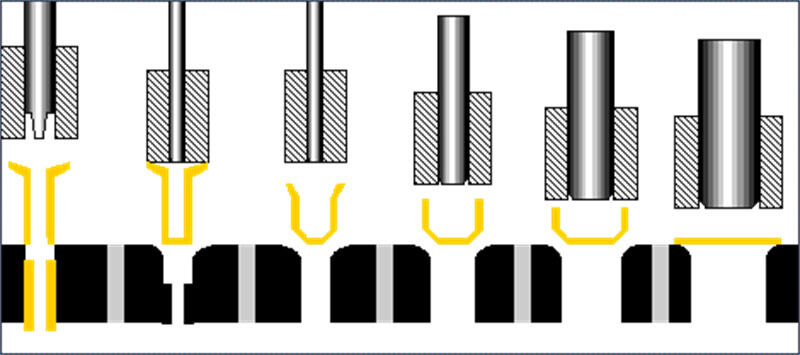

Sự chính xác là yếu tố then chốt trong quá trình sản xuất các tấm thân xe. Các công nghệ dập ô tô cho phép nhà sản xuất tạo ra các bộ phận đúc kim loại với thông số kỹ thuật chính xác, đảm bảo rằng các tấm thân xe khớp với nhau hoàn hảo. Sự chính xác này rất quan trọng cho cả độ vững chắc cấu trúc và tính thẩm mỹ của phương tiện. Hơn nữa, sự chính xác trong kim loại đóng dấu ô tô đảm bảo rằng các bộ phận được sản xuất với tốc độ cao mà không làm giảm chất lượng.

Sản xuất dập kim loại ô tô

Lợi thế của công nghệ dập kim loại trong sản xuất thân xe

Một trong những lý do chính kim loại đóng dấu ô tô các bộ phận được sử dụng trong sản xuất thân xe là khả năng sản xuất các linh kiện có độ chính xác cao với tốc độ nhanh. Nhà sản xuất các bộ phận dập sử dụng công nghệ tiên tiến công nghệ dập ô tô máy móc để tạo ra các bộ phận có chất lượng nhất quán, điều này rất quan trọng cho việc sản xuất hàng loạt phương tiện.

Ngoài ra, các bộ phận đúc kim loại cung cấp độ bền cần thiết trong khi giữ trọng lượng tổng thể của phương tiện ở mức thấp. Sự cân bằng này rất quan trọng để cải thiện hiệu suất tiêu thụ nhiên liệu và đáp ứng các tiêu chuẩn môi trường. Công nghệ tiên tiến công nghệ dập ô tô máy móc giúp các nhà sản xuất tạo ra các hình dạng phức tạp, chẳng hạn như bề mặt cong hoặc uốn lượn, với độ chính xác cao và ít phế liệu.

Sản xuất nhanh khuôn dập kim loại

Sản xuất hàng loạt tiết kiệm chi phí với công nghệ dập kim loại

Dịch vụ dập kim loại cung cấp một phương pháp hiệu quả để sản xuất số lượng lớn linh kiện nhanh chóng và tiết kiệm chi phí. Bằng cách sử dụng công nghệ dập ô tô công nghệ, các nhà sản xuất có thể đáp ứng nhu cầu sản lượng cao trong khi vẫn duy trì chất lượng cao, điều này rất cần thiết cho ngành công nghiệp ô tô cạnh tranh.

Các thành phần chính được sản xuất bằng công nghệ dập kim loại trong khung gầm xe

Trong quá trình sản xuất khung gầm xe , đột dập ô tô các bộ phận được sử dụng để tạo ra các thành phần cấu trúc như thanh ngang, khung phụ và điểm gắn treo. Những bộ phận này rất quan trọng để đảm bảo độ bền và độ cứng tổng thể của xe.

Dịch vụ dập kim loại giúp đỡ nhà sản xuất các bộ phận dập sản xuất số lượng lớn các bộ phận chính xác cần thiết cho hệ thống khung gầm. Các thành phần như than ray khung gầm và đáy sàn thường được sản xuất bằng cách sử dụng các bộ phận đúc kim loại do yêu cầu về độ mạnh cao và nhu cầu sản xuất hàng loạt tiết kiệm chi phí.

Vai trò của sự chính xác trong các thành phần khung gầm

Khi sản xuất khung gầm các thành phần, điều quan trọng là các bộ phận phải chính xác và bền bỉ. The công nghệ dập ô tô công nghệ cho phép kim loại đóng dấu ô tô các bộ phận đáp ứng các tiêu chuẩn nghiêm ngặt dành cho các thành phần cấu trúc. Điều này đảm bảo độ mạnh mẽ và an toàn tổng thể của phương tiện, làm cho sự chính xác trở thành một khía cạnh quan trọng trong quá trình sản xuất khung gầm.

Tại sao nên chọn Dịch vụ Đánh Dấu Kim Loại cho Sản xuất Ô tô?

Cho nhà sản xuất các bộ phận dập , cung cấp dịch vụ dập kim loại cho sản xuất ô tô mang lại nhiều lợi thế. Trước hết, bấm kim loại là một phương pháp hiệu quả cao để sản xuất số lượng lớn các bộ phận nhanh chóng. Điều này giúp các nhà sản xuất ô tô đáp ứng lịch trình sản xuất khắt khe đồng thời duy trì tiêu chuẩn chất lượng cao.

Ngoài ra, công nghệ tiên tiến công nghệ dập ô tô đảm bảo việc sản xuất các bộ phận chất lượng cao với ít khiếm khuyết nhất. Điều này rất cần thiết trong ngành công nghiệp ô tô, nơi các bộ phận phải tuân thủ các tiêu chuẩn an toàn và quy định nghiêm ngặt. Dịch vụ dập kim loại cũng giảm chi phí sản xuất mà vẫn giữ được chất lượng, cho phép các nhà sản xuất duy trì khả năng cạnh tranh.

Tiết kiệm Chi phí và Thời gian trong Sản xuất Ô tô

Bằng cách sử dụng kim loại đóng dấu ô tô công nghệ, nhà sản xuất các bộ phận dập có thể đạt được tiết kiệm đáng kể về thời gian và chi phí trong việc sản xuất các bộ phận ô tô. Dù là để sản xuất thân xe hoặc khung gầm các thành phần, các bộ phận đúc kim loại cung cấp một giải pháp đáng tin cậy và hiệu quả đáp ứng các tiêu chuẩn cao của ngành công nghiệp ô tô.

Kết luận: Tương lai của công nghệ dập kim loại trong sản xuất ô tô

Khi ngành công nghiệp ô tô phát triển, nhu cầu về các bộ phận hiệu suất cao kim loại đóng dấu ô tô linh kiện sẽ tiếp tục tăng lên. Sự phát triển của công nghệ công nghệ dập ô tô sẽ cho phép nhà sản xuất các bộ phận dập sản xuất các linh kiện phức tạp hơn, có độ bền cao hơn với chi phí thấp hơn. Dù là để sản xuất thân xe hoặc khung gầm , các bộ phận đúc kim loại sẽ vẫn giữ vai trò quan trọng trong sản xuất ô tô.

Khi ngành công nghiệp chuyển hướng toward các phương tiện bền vững và nhẹ hơn, dịch vụ dập kim loại sẽ đóng vai trò ngày càng quan trọng trong việc đáp ứng những nhu cầu này. Bằng cách cung cấp các giải pháp sáng tạo và sản xuất chất lượng cao, bấm kim loại sẽ tiếp tục định hình tương lai của ngành sản xuất ô tô.