Kā auto formēšanas daļas tiek izmantotas transportlīdzekļa karosēženijas un šassi ražošanā

Automobilu ražošanas nozarē, metāla stampēšanas avtomobļu daļiņas ir būtiskas transportlīdzekļu galveno komponentu ražošanai. Procesa, kas saistīts ar formēšana automašīnām daļiņu ražošanu, mērķis ir piemērot spiedienu metāla lapiņai, lai to formas saskaņā ar vēlamo dizainu. Šis process ir ļoti svarīgs komponentu ražošanai, kas ietekmē transportlīdzekļa struktūras drošību, drošību un kopējo veiktspēju. Šajā ziņā mēs pārrunāsim, kā automobiļu formēšanas preses tehnoloģija tiek izmantota transportlīdzekļa karosērijas un šasija komponentu ražošanā.

Auto formēšanas daļiņu loma transportlīdzekļa karosērijas un šases ražošanā

Runājot par transportlīdzekļu ražošanu, auto karosaža un šasija ir galvenie elementi jebkuram transportlīdzeklim. Šie komponenti ir jābūt viegliem, tomēr izturīgiem, lai nodrošinātu transportlīdzekļa veiktspēju, drošību un degvielas efektivitāti.

Formēšana automašīnām daļas tiek izgatavotas, lai atbilstu sarežģītajiem prasībām, kas saistītas ar transportlīdzekļa karosērijas un šasija izstrādi. Komponenti, piemēram, durvju plāksnes, riteņu klājas un šases rāmis parasti tiek izgatavoti, izmantojot metāla formēšanas pakalpojumi - Jā. Parasti metāla formēšanas daļas izgatavotas šajā procesā ir precīzi formas, lai atbilstu transportlīdzekļa specifikācijām.

metāla formēšanas pakalpojumi

Piemēram, automobiļu formēšanas preses tiek izmantots, lai izveidotu bāzes svarīgās plāksnes, piemēram četrtplāksnes , skaistmateriāli , un bumpieri , kas veicinājot gan estētiskos, gan funkcionalos mērķus. Šiem daļām jāatbilst stingriem spēcības, ilgtspējas un izmēru precizitātes standartiem.

Kāpēc precizitāte ir svarīga auto formēšanā šķūņa plāksnēm

Precizitāte ir galvenā šķūņa plāksnēm ražošanas procesā. automobiļu formēšanas preses dod ražotājiem iespēju izveidot metāla formēšanas daļas ar precīzi noteikumiem, nodrošinot, ka šķūņa plāksnes pievienojas savstarpēji perfekti. Šī precizitāte ir būtiska gan transportlīdzekļa struktūras drošībai, gan arī vizuālajam izskatam. Turklāt precizitāte metāla stampēšanas avtomobļu nodrošina, ka daļas tiek ražotas augstā ātrumā, nezaudējot kvalitāti.

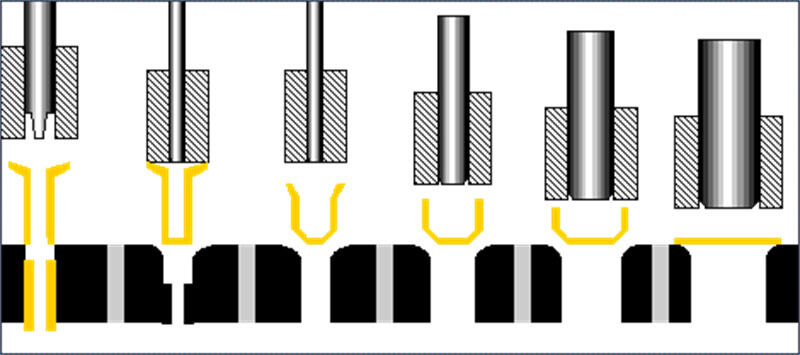

Auto formēšanas ražošana

Metalformēšanas priekšrocības transportlīdzekļu korpusa ražošanā

Viens no galvenajiem iemesliem, metāla stampēšanas avtomobļu kāpēc daļas tiek izmantotas automašīnu korpusa ražošanā, ir iespēja ražot augstas precizitātes komponentus ātrā tempā. Formēšanas daļu ražotājiem izmanto modernas automobiļu formēšanas preses mašīnas, lai radītu daļas ar konstantu kvalitāti, kas ir būtiski masveida automašīnu ražošanai.

Turklāt metāla formēšanas daļas sniedz nepieciešamo stiprumu, vienlaikus saglabājot automašīnas kopējo svaru zemā līmenī. Šis līdzsvars ir būtisks, lai uzlabotu degvielas efektivitāti un atbilstu vides standartiem. Modernās automobiļu formēšanas preses mašīnas ļauj ražot sarežģītus formas piemēram, liecināmus vai konturētus virsmas, ar augstu precizitāti un minimālu atkritumu daudzumu.

Ātra metāla formu ražošana

Izkustīgs masveida ražošanas ar metāla formēšanu

Metāla formēšanas pakalpojumi sniedz efektīvu metodi, lai ātri un ekonomiski ražītu lielu daudzumu daļām. Izmantojot automobiļu formēšanas preses tehnoloģiju, ražotāji var apmierināt augstas ražošanas prasības, saglabājot augstu kvalitāti, kas ir būtiski konkurencespējīgajai automašīnu nozarē.

Galvenie komponenti, ko metalu formēšana izmanto transportlīdzekļa šassis ražošanā

Ražošanas procesā transportlīdzekļa šassis , formēšana automašīnām daļas tiek izmantotas struktūras komponentu veidošanai, piemēram, krustveidīgajiem ločiem, subrāmjiem un suspensijas montāžas punktiem. Šīs daļas ir kritiskas, lai nodrošinātu transportlīdzekļa kopējo stiprumu un stingrību.

Metāla formēšanas pakalpojumi palīdz formēšanas daļu ražotājiem izstrādāt lielu daudzumu precīzu daļu, kas nepieciešamas šassis sistēmām. Komponenti, piemēram, šassis riteņi un podas elementi parasti tiek izgatavoti, izmantojot metāla formēšanas daļas dēļ to augstās stipruma prasības un nepieciešamība pēc ekonomiski efektīvas masveida ražošanas.

Precizitātes loma šassis komponentos

Izstrādājot šasija komponentus, ir būtiski, lai daļas būtu gan precīzas, gan ilgtspējīgas. automobiļu formēšanas preses tehnoloģija ļauj metāla stampēšanas avtomobļu daļām atbilst striktajām specifikācijām, kas nepieciešamas struktūras komponentiem. Tas nodrošina transportlīdzekļa kopējo stiprumu un drošību, padarot precizitāti par galveno aspektu šassis ražošanas procesā.

Kāpēc izvēlēties metāla formēšanas pakalpojumus automobiļu ražošanai?

Priekš formēšanas daļu ražotājiem , kas piedāvā metāla formēšanas pakalpojumi automobiļu ražošanai sniedz daudzus priekšrocības. Pirmkārt un galvenokārt, metāla formēšana ir ārkārtīgi efektīva metode, lai ātri izgatavotu lielu daudzumu daļiņām. Tas palīdz automobiļu ražotājiem izpildīt pieaugošos ražošanas grafikus, saglabājot augstas kvalitātes standartus.

Turklāt, uzlabotā automobiļu formēšanas preses tehnoloģija nodrošina augstas kvalitātes daļiņu ražošanu ar minimāliem defektiem. Tas ir būtiski automašīnu nozarē, kur komponentiem jāatbilst striktiem drošības un regulatīvajiem noteikumiem. Metāla formēšanas pakalpojumi arī samazina ražošanas izmaksas, saglabājot kvalitāti, ļaujot ražotājiem palikt konkurencespējīgiem.

Izmaksu un laika efektivitāte automašīnu ražošanā

Izmantojot metāla stampēšanas avtomobļu tehnoloģiju, formēšanas daļu ražotājiem var sasniegt nozīmīgas ietaupījumus laikā un naudā, ražojot automašīnu daļiņas. Vai arī tā ir paredzēta transportlīdzekļa karosērijas vai šasija komponentiem, metāla formēšanas daļas sniedz uzticamu un efektīvu risinājumu, kas atbilst automašīnu nozares augstajiem standartiem.

Secinājums: Metāla iespiedēšanas nākotnes perspektīva automobiļu ražošanā

Tā kā automobiļu rūpniecība attīstās, pieprasījums pēc augstas veiktspējas metāla stampēšanas avtomobļu daļas turpinās augt. Izstrādājumu attīstība automobiļu formēšanas preses tehnoloģijas ļaus formēšanas daļu ražotājiem lai ražotu sarežģītākas, izturīgāku sastāvdaļas ar zemākiem izdevumiem. Vai gan transportlīdzekļa karosērijas vai šasija , metāla formēšanas daļas būs būtiski automobiļu ražošanā.

Tā kā nozare virzās uz ilgtspējīgākiem un vieglākiem transportlīdzekļiem, metāla formēšanas pakalpojumi eiropas Savienība un tās dalībvalstis, kas ir iesaistītas šajā jomā, ir ļoti ieinteresētas, lai nodrošinātu, ka Eiropas Savienība un tās dalībvalstis, kas iesaistītas šajā jomā, sadarbojas, lai nodrošinātu, ka Eiropas Savienība un tās dalībvalstis, kas iesaistītas šajā jomā, sadarbojas un sadarbojas. Piešķirot inovatīvus risinājumus un kvalitatīvu ražošanu, metāla formēšana turpinās veidot automobiļu ražošanas nākotni.

Mažas partijas, augsti standarti. Mūsu ātra prototipēšanas pakalpojums padara validāciju ātrāku un vieglāku —

Mažas partijas, augsti standarti. Mūsu ātra prototipēšanas pakalpojums padara validāciju ātrāku un vieglāku —