To del iz kovinske pločevine za avtomobilsko industrijo je zelo pomembno, ker če deli ne passe, potem ničesar ne bo delovalo. Še ena prednost točkanja je, da zmanjša količino kovinskega materiala pri izdelavi delov. To zmanjša stroške in težo avtomobila, kar ga dela hitrejšega in učinkovitejšega. Nazadnje omogoča točkanje tela avtomobila lažje in hitreje oblikovanje delov, zato imajo fabrike manj časa za masovno proizvodnjo avtomobilov. In to je zelo koristno, ko želi veliko ljudi kupiti avtomobile.

Otpreševanje karoserije avtomobila igra ključno vlogo ne le v obstoječih avtomobilih, temveč bo pomagalo tudi oblikovati prihodnost avtomobilov. AVTOMobili: avtomobili v prihodnje morajo biti še močnejši, močnejši, varnejši in bolj gorivno učinkoviti. S pomočjo otpreševanja karoserije se lahko deli izdelajo na tak način, da pomagajo zaščititi ljudi. Na primer, v primeru sudarja se lahko deli izdelajo tako, da absorbirajo energijo in tako zaščitijo potnike v avtomobilu. Poleg tega s posredovanjem najnovejše tehnologije otpreševanja omogočamo izdelavo delov z nepojavičnimi obliki, ki omogočajo avtomobilom prevarovati vetar in zmanjšati porabo goriva ter emisije onesnažujočih snovi. To odlagališke avtomobilske deli pomeni, da bodo pri misli na avtomobile jutri otpreševalne postopki glavni prispevki k zagotavljanju, da bodo varni in odgovorni vozilski park.

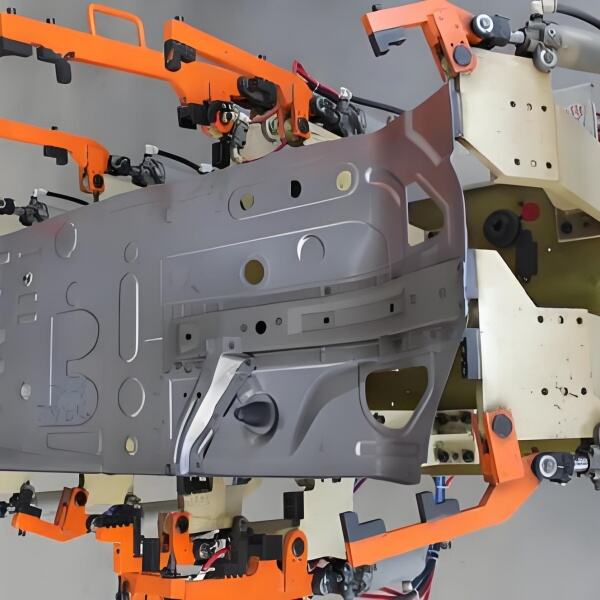

Otrošne stroje za očrpe zagotavljajo deli, ki jih proizvajalci avtomobilov uporabljajo na vseh vozilih, od enostavnih malih avtomobilov do težkih tovornjakov. Hitrost in natančnost pri proizvodnji delov je tudi ključna za izpolnitev zahtev strank in prevzemanje konkurentov. Poleg tega pomaga očrpanje karoserije proizvajalcem pri gradnji velikega števila delov samostojno, kar pomožno shranjuje denar in hkrati ohranja visoko kakovost delov. S tem lahko oni deli iz kovinskih pločevin za avtomobilsko industrijo zavarantirajo, da je vsako vozilo dobro zgradeno in varno v uporabi.

Vse te podrobnosti so zelo pomembne za učinkovito prilagajanje, da se zagotovi, da dobavitelji avtomobilske kovinske odlagarne so deli pravilno izdelani. Organizacijam je tudi potrebno vlagati v najnovejše tehnologije zaradi stalno spreminjajočih standardov varnosti in učinkovitosti. Nazadnje potrebujejo delavce, ki vedo, kako uporabljati stroje in reševati težave, če se pojavijo med očrpanjem. Postopek očrpanja je lahko zelo odvisen od teh faktorjev, in imeti raznovrstno ekipo je ključna razlika.

Shaoyi je vodilni ponudnik rešitev za izdelavo točkarskih avtomobilov. Oni avtomobilske deli iz listne jekline vključujejo različne vrste točkar, vsebine hidrauličnih in servo-pogonomih, da izpolnijo vaše potrebe.

Naša družba je ponosna, ker imamo posvečeno raziskovalno in razvojno skupino, v kateri vsak inženir ima več kot desetletje izkušenj v avtomobilski industriji. Ta izkušnja nam omogoča, da razumemo edinstvene značilnosti različnih tehnik in materialov, kar nam omogoča, da ponujamo prilagojene rešitve za naše stranke. Ponujamo strokovno analizo CAE, razvoj in tehnično pomoč ter kompleksne poročila DFM, da se zagotovi, da je vsak aspekt načrta prilagojen za proizvodnjo. Posvečeni smo inovacijam in izdelavi visokokakovostnih metalnih delov, ki zadovoljijo zahteve naših strank.

Naše podjetje, ki pokriva več kot 10.000 kvadratnih metrov in se osredotoča na proizvodnjo kovinskih komponentov za več kot 30 avtomobilske znamke, ima več kot 15 let izkušenj v poslovanju. Uporabljamo napredne obdelovalne tehnike, vsebine štampovanje, CNC obratovalni stroji, izdelava matric in gredelno litje aluminija, da se zagotovi, da je vsak izdelek proizveden po najvišjih standardih kakovosti. Naše stroge postopke nadzora kakovosti zagotavljajo, da ostanejo naši izdelki stalni glede na razsežnosti, obliko, obliko in delovanje. To povečuje zaupanje in zaupanje s strani naših strank.

Več kot 90 % naših izdelkov je namenjeno avtomobilski industriji. Ponujamo kakovostne deli, ki so primerni za širok obseg vozil, vključno s potniškimi avtomobili, golfskimi vožili, poslovnimi vozili ter motorji, kamiony in traktorji. Naša raznolika ponudba izdelkov je dokaz naše sposobnosti, da izpolnimo vse zahteve trga za avtomobile. Privilegirani smo tudi kot glavni ponudnik suspendijskih sistemov Volkswagenu v Kitajski, kar pokaže našo sposobnost ponuditi zanesljive in revolucionarne rešitve najprestigiješim avtomobilskim znamkam. Naše dolgoročno industrijsko znanje omogoča, da naši izdelki ne le izpolnjujejo, ampak presegajo očakovanja strank glede zmogljivosti in kakovosti.

Zelo smo ponosni, da smo prejeli potrdilo IATF 16949, ki je potrdilo visokih standardov upravljanja kakovosti, ki jih želimo doseči v avtomobilski industriji. Oddelek za kakovost ima nadzor pet ključnih orodij za kakovost, ki vključujejo Statistično nadzorovanje procesa (SPC), Analizo merilnih sistemov (MSA), Analizo posledic in pomembnosti napak (FMEA), Napredno načrtovanje kakovosti izdelka in Postopek odobritve proizvodnih delov. Poleg tega je osebje za kakovost zaključilo obsežno šolanje v okviru Six Sigma, kar zagotavlja, da sledimo najvišjim standardom kakovosti izdelkov. Naš celovit pristop k upravljanju kakovosti zagotavlja, da vsak in vsakdanji izdelek, ki ga prodajamo, ne le izpolnjuje, ampak pogosto presegne industrijske pričakovanja, s čimer našim strankam zagotavljamo popolno zaupanje in zadovoljstvo z našimi izdelki.