With years of experience, Chassis Welded Assemblies is committed to delivering innovative product stability and strength, specializing in auto sheet metal welding to meet the demands of the automotive industry.

Auto stamping parts combine CAE analysis with lean manufacturing practices, effectively reducing development cycles and costs while ensuring high precision and reliability.

We offer 24-hour quotations and a 72-hour rapid design capability for CNC automotive parts, ensuring swift responses to meet customer needs efficiently.

Shaoyi specializes in the design and manufacturing of automotive stamping dies, offering precision-engineered solutions to meet complex production requirements. Our molds ensure high efficiency and consistency, making them the ideal choice for automotive applications.

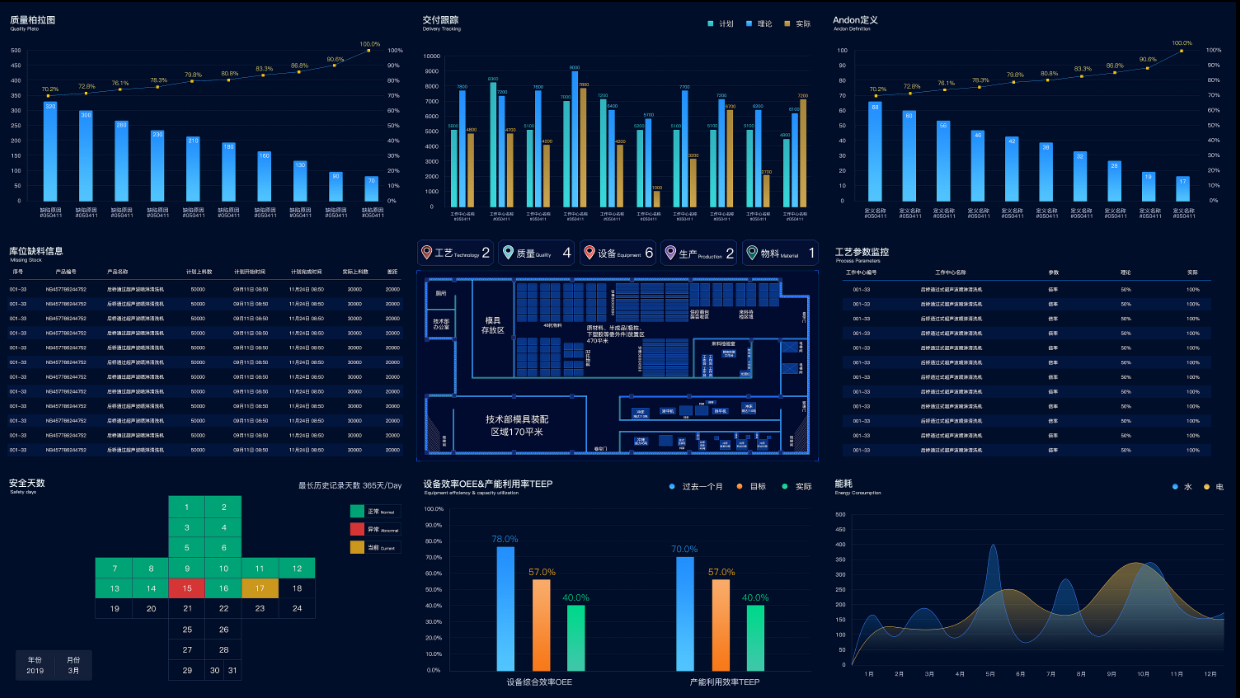

We’ve integrated advanced digital management systems into our operations, revolutionizing how we approach manufacturing in the automotive parts industry. This technology enhances efficiency, improves accuracy, and allows for real-time monitoring and optimization of every process. As a result, we can offer faster turnaround times, reduced costs, and consistently high-quality products tailored to meet the demanding standards of the automotive sector.

Our project management process ensures every phase, from design to production, is executed with precision and efficiency, meeting industry standards and accommodating the unique needs of customized automotive metal parts with timely delivery.

Detailed drawings and technical requirements are provided to define product specifications and standards.

A precise cost estimate and project quote are generated based on the requirement analysis.

Resources are allocated, and the project officially begins after quote approval.

CAE analysis and preliminary planning ensure design and manufacturing feasibility.

Initial samples and soft molds are developed, followed by design verification (DV)

Rigorous testing and validation are conducted to ensure design compliance.

Production Validation (PV) samples are provided, and Production Part Approval Process (PPAP) is completed.

A small-scale trial production is conducted in a production environment to validate the process.

Final mass production is approved and initiated.

Our engineer design team has more than ten years of design experience in the automotive industry and is very good at technical analysis and project management.

By improving our production processes and leveraging cutting-edge manufacturing technologies, Shaoyi enables automotive industry clients to accelerate project production schedules and maintain a competitive advantage.

Shaoyi's quality control team carefully inspects each custom part to ensure it meets the highest standards of the automotive industry, delivering reliable and precise components.

With over a decade of experience in the automotive sector, we've served leading auto parts companies, and our products are ultimately used by mainstream carmakers.

We adopt streamlined management, assign dedicated sales consultants to each customer, and respond quickly to quotations within 24 hours.

Our company promotes sustainable development by utilizing green photovoltaic energy.

Give you a different co-operation experience

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.