Over the years, Shaoyi, as a leading automotive stamping supplier in China, has earned the trust of numerous automotive industry customers and emerged as a leading manufacturer in the automotive component manufacturing industry. With our extensive project experience in stamping auto parts, we are committed to providing our customers with high-quality and efficient stamping services, continuously meeting the new challenges and innovative demands of the automotive industry.

IATF TS16949:2016/Critical to Quality

Factory Area

R&D Engineer

Steel & Aluminum

We use a variety of quality control methods to ensure that the products we deliver to our customers are of the right size and performance for their needs.

Our unwavering commitment to quality is bolstered by our IATF 16949 certification, ensuring a stringent quality control system throughout every phase of production. This certification reflects our meticulous approach to manufacturing automotive stamping parts, from the initial design to the final product delivery, guaranteeing exceptional performance and reliability.

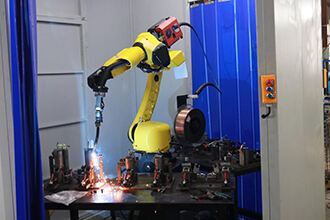

Leveraging top-tier production and inspection equipment, our state-of-the-art, fully automated machinery guarantees product quality at every step, ensuring consistency and excellence in every output of metal stamping car parts.

Our team of technical experts, each with over a decade of experience in metal fabrication, forms the backbone of our operations. These elite engineers bring a wealth of knowledge and expertise to every project, ensuring that our stamping automotive parts not only meet but exceed industry standards for quality and innovation.

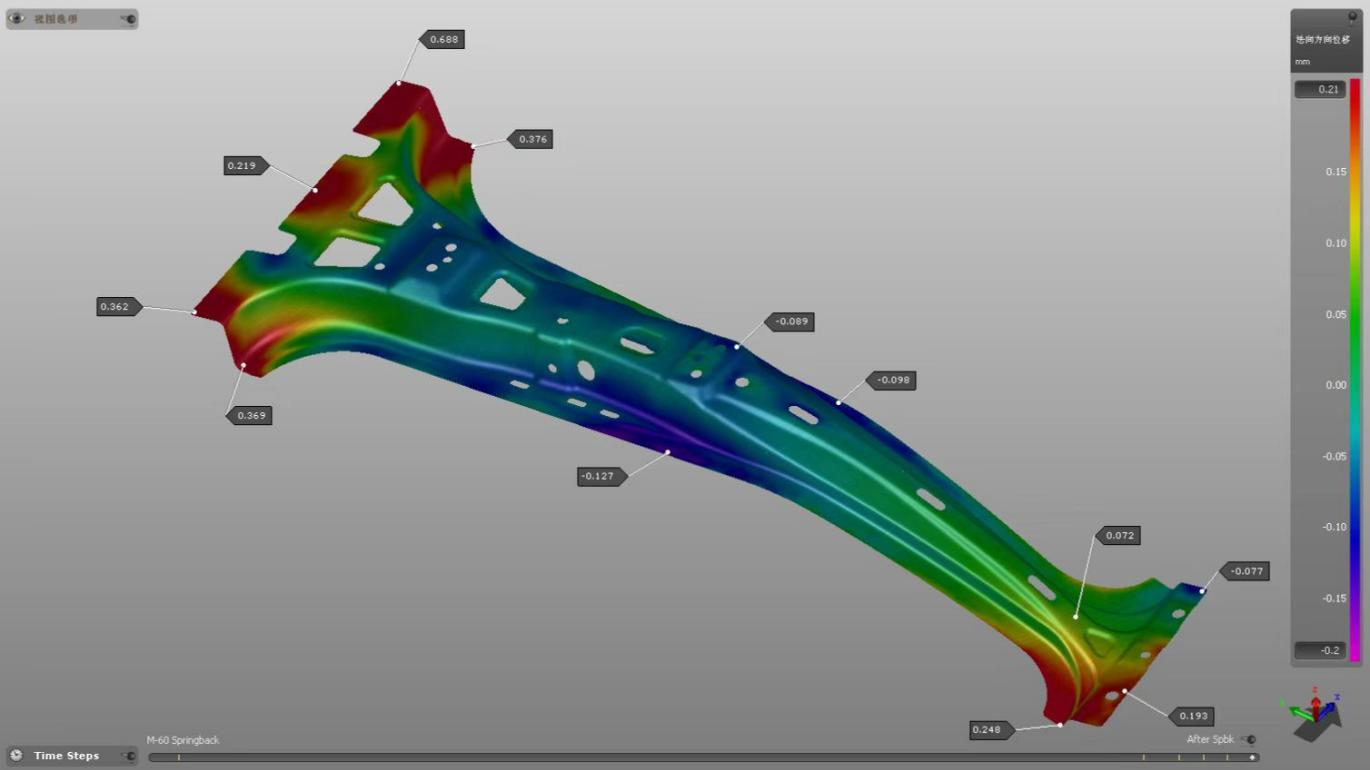

There are many design elements involved in creating parts for metal stamping car parts—design for cost, quality, assembly, and manufacturability. That landscape can be challenging at times. At ShaoYi, we provide automated design analysis on CAD models, UG, and CAE that highlights features in your part design that can be adjusted for manufacturability. It’s a great design resource right at your fingertips. To keep design advisories at a minimum and optimize part design, we created this helpful kit of metal stamping resources.

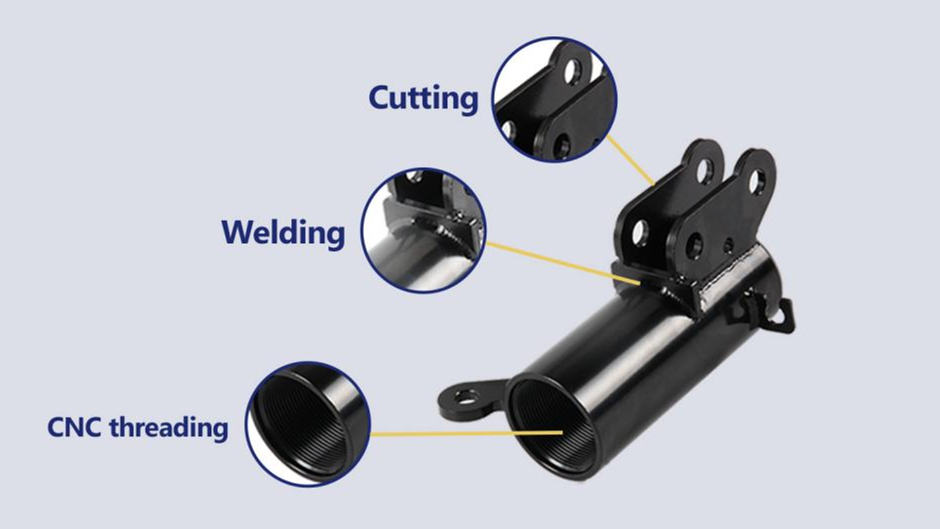

Combination of metal stamping with other processes such as CNC, laser cutting, progressive die, three-dimensional forming, cold heading, and forging allows us to select the most optimal process for your automobile stamping parts. Among these, we choose the one with the highest material utilization, production stability, and efficiency during the product's preliminary design phase, ensuring cost-effective and high-quality results.

A wide range of materials, including various types of steel (mild, stainless, high-strength), aluminum, brass, allows for the production of automotive metal stamping parts with specific properties tailored to their end-use applications. This diverse selection ensures that each part is optimized for its unique requirements, delivering durability, strength, and precision for automotive components.

Our Facilities leverage various presses from 100-600 ton capacity to produce a wide range of custom metal stamping parts. Components utilizing materials of low-carban steel in thickness from 1mm to 12mm

Standardized,process-oriented refined production standards efforts to provide you with up to 99.8%qualified string of precision parts

Pre-manufacturing feasibility assessment and optimization

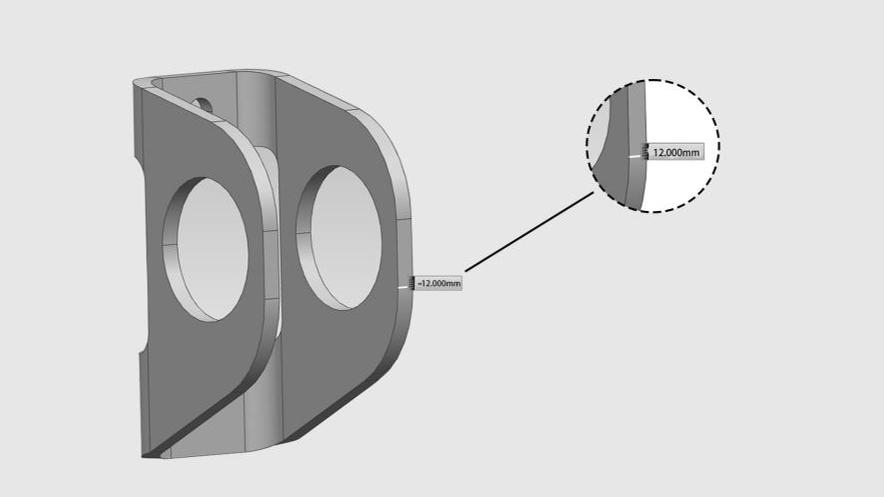

Benchmarking,assembly,and inspection criteriadevelopment foridentification of key dimensions

For DFM and work instructions standard full-sizeinspection proofing process problems

Summarize the proofing problems, close the problerpointsand continuously optimize the productlon process

Determine the correctness of the manufacturing process and that the product meets the customer's specifications and process requirements.

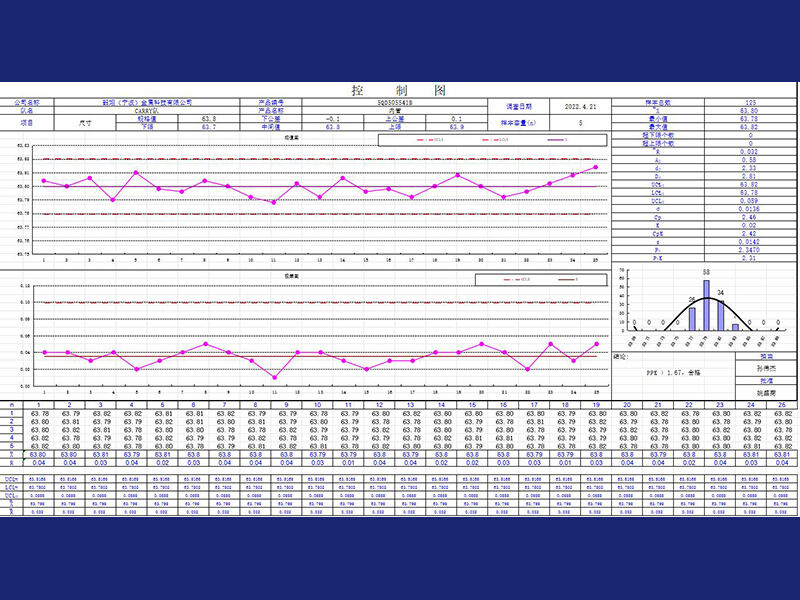

Control of special requirements and processesimplementation of CPK>l.33 for key dimensions

Perform according to FQC standards and requirements for car part stamping, ensuring precision and consistency throughout the production process.

Through precise data monitoring and process optimization, we ensure timely delivery of products.

| Processing Capabilities | Remark | ||

| StampingMaximum Part Size | The maximum width of the coil material is 600mm, and the maximum thickness T is 6.0mm | Stamping Maximum Part Size | The three-in-one feeding machine equipped with a 315 ton punch can only limit the material thickness to within 6.0mm |

| Stamping Minimum Part Size | The Minimum width of the coil material is 300mm, and the Minimum thickness T is 1.0mm | Stamping Minimum Part Size | The 160T punch is equipped with an old-fashioned feeder, with a material thickness of no less than 1.0mm |

| Stamped Product Tolerances | 0.05mm (punching tolerance) | ||

| Resistance Welding Strength | 25KN (pull-off force experiment) | ||

| Electrophoresis | Film thickness 15-35um, salt spray test 720h without red rust | ||

| Dacromet | Film thickness 8um, salt spray test 720h without red rust | ||

| Galvanization | Film thickness 8-15um, salt spray test 240h without red rust | ||

| Galvanized nickel | Film thickness 8-15um, salt spray test 1500h without red rust |

| Manufacturing Processes and Materials | Manufacturing Processes and Materials | ||

|---|---|---|---|

|

Steel Plate |

Hot dip galvanized sheet |

Aluminum Plate

|

5052 Stretched Aluminum Plate |

Focus on chassis welded assemblies, shock-absorbing welded assemblies, chassis stamping, and machining parts.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.