Shaoyi has become a trusted leader in producing automobile chassis parts, specializing in advanced welding techniques. With our expertise in chassis welding, we deliver durable, high-performance components that meet the strict demands of the automotive industry. Our focus on precision and efficiency ensures strong, reliable connections, continuously addressing the evolving needs of automotive manufacturing.

IATF TS16949:2016/Critical to Quality

Factory Area

R&D Engineer

Steel & Aluminum

We use a variety of quality control methods to ensure that the car chassis parts we deliver meet the precise size and performance specifications required for their applications.

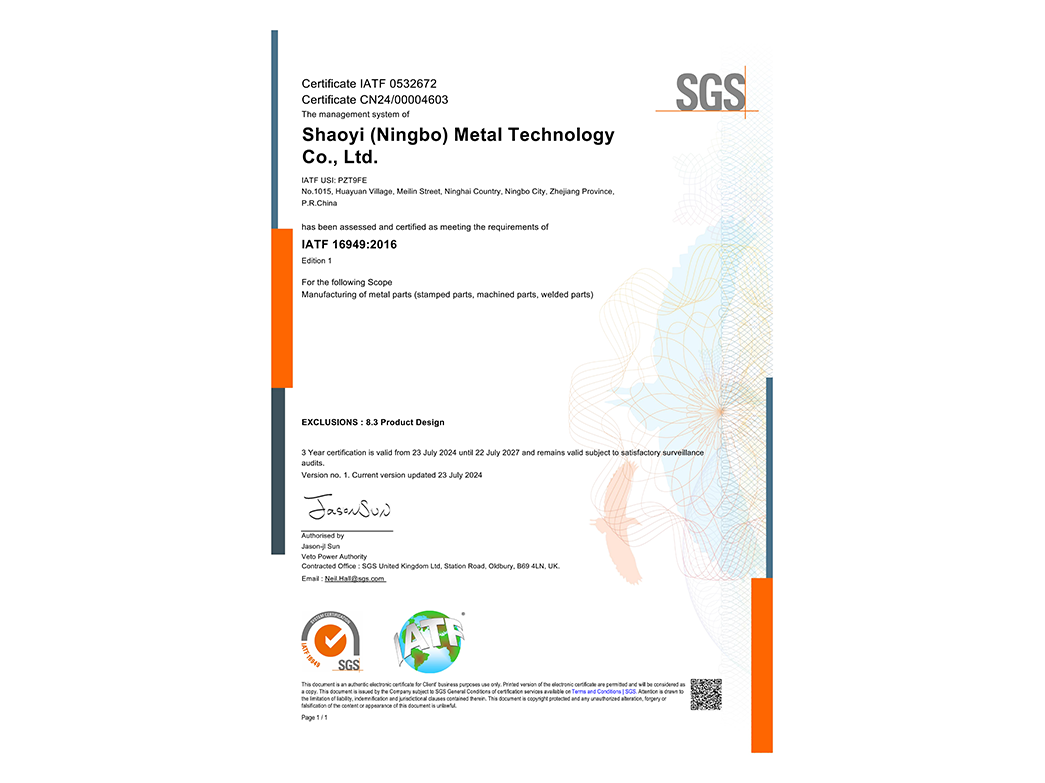

Our unwavering commitment to quality is bolstered by our IATF 16949 certification, ensuring a stringent quality control system throughout every phase of production. This certification is a testament to our meticulous approach, from the initial design to the final product delivery. -IATF16949 Certification

Leveraging top-tier production and inspection equipment, our state-of-the-art, fully automated machinery guarantees product quality with every manufacturing process, ensuring consistency and excellence in every output.

Our team of technical experts, each with over a decade of experience in metal fabrication, forms the backbone of our operations. These elite engineers bring a wealth of knowledge and expertise to every project, ensuring that our products not only meet but exceed industry standards for quality and innovation.

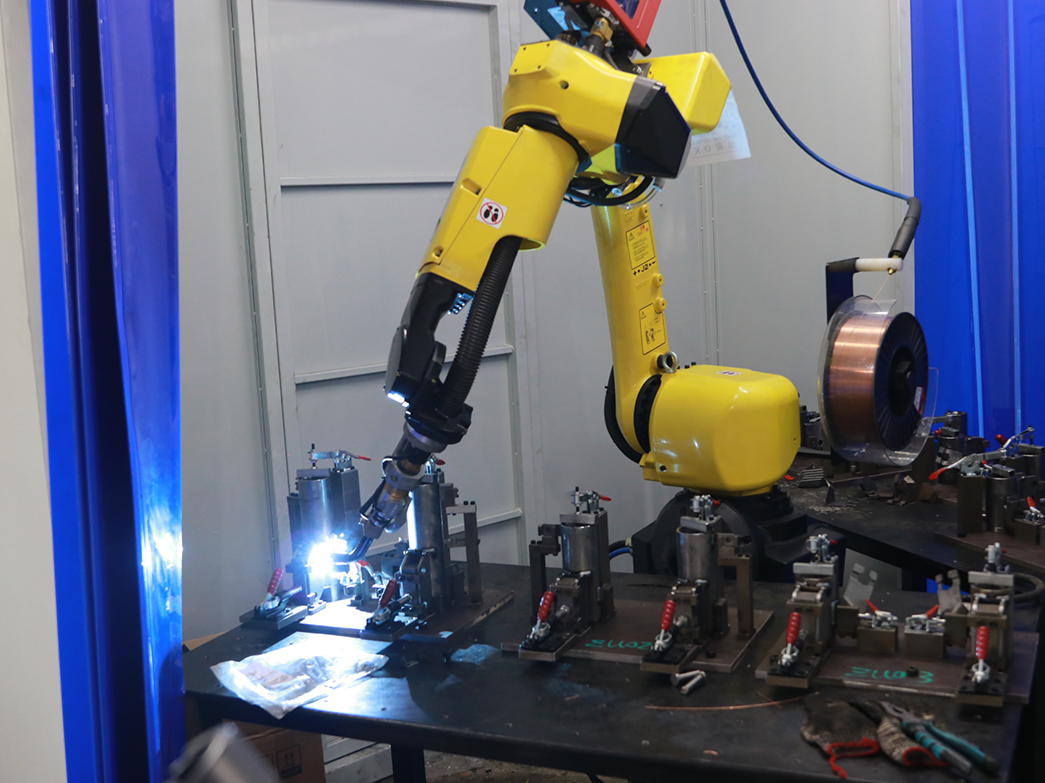

Our robotic welding production line brings precision, speed, and consistency to every project, especially in automobile chassis and body engineering. By automating the welding process, we enhance production efficiency, reduce human error, and ensure high-quality, uniform welds across all weld chassis components. This technology allows us to meet tight deadlines while maintaining top-notch quality, offering a reliable and cost-effective solution for your manufacturing needs.

We utilize state-of-the-art automated welding equipment and technology to ensure the precision and consistency of every weld, particularly for car chassis components. Our welding processes minimize human error, guaranteeing high-quality, strong weld joints that are ideal for complex designs and demanding projects in automobile manufacturing.

Our automated welding technology streamlines the production of chassis components, improving efficiency and reducing cycle times. With continuous operation and minimal downtime, we ensure faster production and quick delivery, meeting deadlines without compromising on the quality of your chassis components.

Versatility in Materials and Processes We are capable of welding various metals, including stainless steel, aluminum, and carbon steel, to deliver high-quality solutions for chassis system components. Whether it's MIG welding or TIG welding, we provide the optimal welding methods to meet the specific needs of each project, ensuring durability and precision.

Our welding team is AWS certified and adheres to the IATF 16949 Quality Management System. We conduct rigorous quality inspections for every welding project to ensure defect-free welds and deliver high-quality products that meet our clients' stringent requirements.

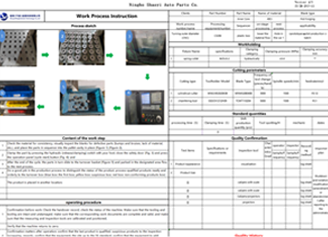

Standardized,process-oriented refined production standards efforts to provide you with up to 99.8%qualified string of precision parts

Pre-manufacturing feasibility assessment and optimization

Benchmarking,assembly,and inspection criteriadevelopment foridentification of key dimensions

For DFM and work instructions standard full-sizeinspection proofing process problems

Summarize the proofing problems, close the problerpointsand continuously optimize the productlon process

Determine the correctness of the manufacturing process and that the product meets the customer's specifications and process requirements.

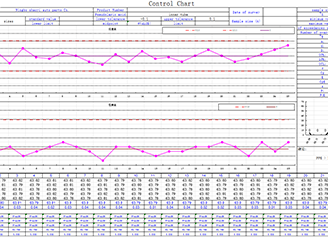

Control of special requirements and processesimplementation of CPK>l.33 for key dimensions

Perform according to AQC standards and requirements

Through precise data monitoring and process optimization, we ensure timely delivery of products.

| Processing Capabilities | Remark | ||

| StampingMaximum Part Size | Maximum coil material width: 600mmMaximum thickness (T): 6.0mm | Stamping Maximum Part Size | The three-in-one feeding machine, paired with a 315-ton punch, imposes a limitation on material thickness, restricting it to within 6.0mm |

| Stamping Minimum Part Size | Minimum width of the coil material is 300mmMinimum thickness (T): 1.0mm | Stamping Minimum Part Size | The 160T punch, equipped with an older-style feeder, requires a material thickness of no less than 1.0mm |

| Stamped Product Tolerances | Punching tolerance:0.05mm | ||

| Resistance Welding Strength | Pull-off force experiment:25KN | ||

| Electrophoresis | Film thickness: 15-35umSalt spray test: 720h without red rust | ||

| Dacromet | Film thickness: 8umSalt spray test: 720h without red rust | ||

| Galvanization | Film thickness: 8-15umSalt spray test: 240h without red rust | ||

| Galvanized nickel | Film thickness: 8-15umSalt spray test: 1500h without red rust |

| Manufacturing Processes and Materials | Manufacturing Processes and Materials | ||

|---|---|---|---|

|

Steel Plate |

Hot dip galvanized sheet |

Aluminum Plate

|

5052 Stretched Aluminum Plate |

Renowned for its versatility and cost-effectiveness, carbon steel is a popular choice for a wide range of applications. Comprising iron and carbon with trace elements, it offers excellent weldability and is readily available. We leverage this robust material for structural components, fabrication projects, automotive parts, and various machinery applications.

Personalized surface treatments elevate the aesthetic appeal, hardness, and smoothness of custom components. These processes enhance chemical resistance and safeguard against corrosion, ensuring the parts' durability. Additionally, they effectively hide visible tool marks resulting from live tooling operations. Below are some of the top treatment options available

| Name | Description | Materials | Color | Texture | |

|

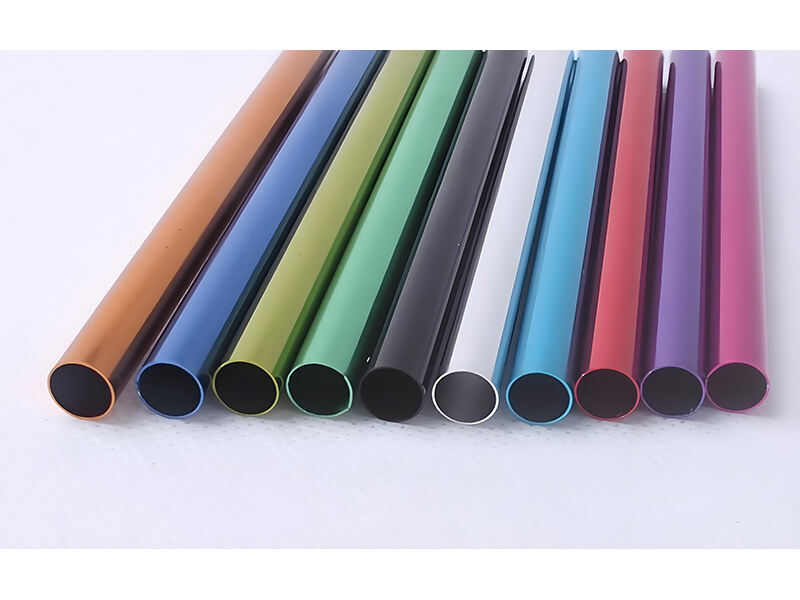

Anodizing | Anodizing is a surface treatment process that enhances the corrosion resistance, wear resistance, and hardness of metals, while also providing protection to the metal surface | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

|

Powder Coating | Powder coating applies dry powder electrostatically to surfaces, offering a durable finish without the need for solvents. It's then hardened with heat or UV light, a clean and efficient alternative to traditional liquid paints. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

|

Electroplating | Electroplating serves multiple purposes like functionality, aesthetics, and corrosion protection. It's widely adopted across industries, with the automotive sector frequently employing it for chrome-plating steel components. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

|

Phosphating | Phosphating is a conversion coating process that forms a crystalline phosphate layer on the surface of metals, primarily used to improve corrosion resistance and provide a better base for subsequent coatings or paints | Steel, Iron, Zinc, Aluminum | N/A | Usually smooth, but the texture can vary depending on the type of phosphate coating used |

|

Spray Painting | Spray painting is a painting process using a device sprayed with compressed air to apply a coating to a surface. It offers a smooth and even finish and is widely used for various materials and applications. | Metal, Wood, Plastic, Fiberglass | Any color | Smooth to semi-gloss, depending on the type of paint and application technique used |

Focus on chassis welded assemblies, shock-absorbing welded assemblies, chassis stamping, and machining parts.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.