01

Raw Material Elemental Inspection Report

Our meticulous elemental analysis of raw materials ensures the chemical composition aligns with quality standards, underpinning the reliability of our manufactured products.

02

Raw Material ELV Inspection Reports

ensure regulatory compliance and environmental responsibility by verifying the absence of prohibited substances in the materials we utilize, aligning with the automotive industry's strict ecological standards.

03

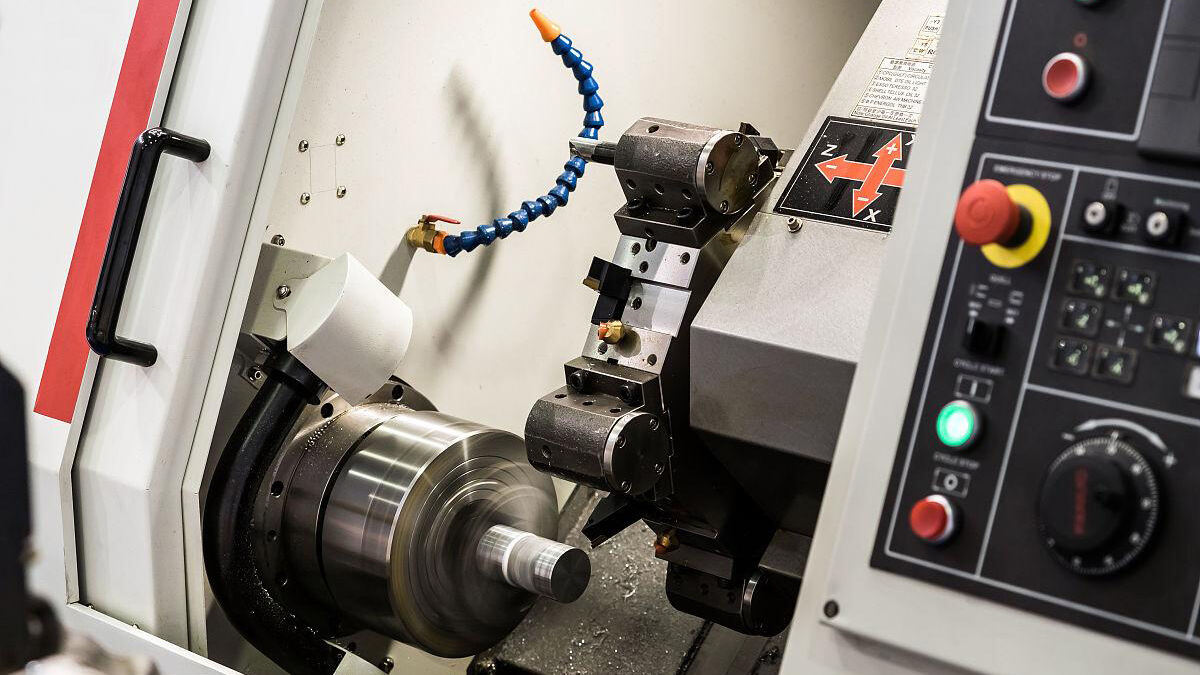

Mechanical Performance Inspection

The reliability and durability of metal parts is ensured by evaluating the material's strength, hardness, toughness, and other key metrics to predict how the material will perform in real-world working environments.

04

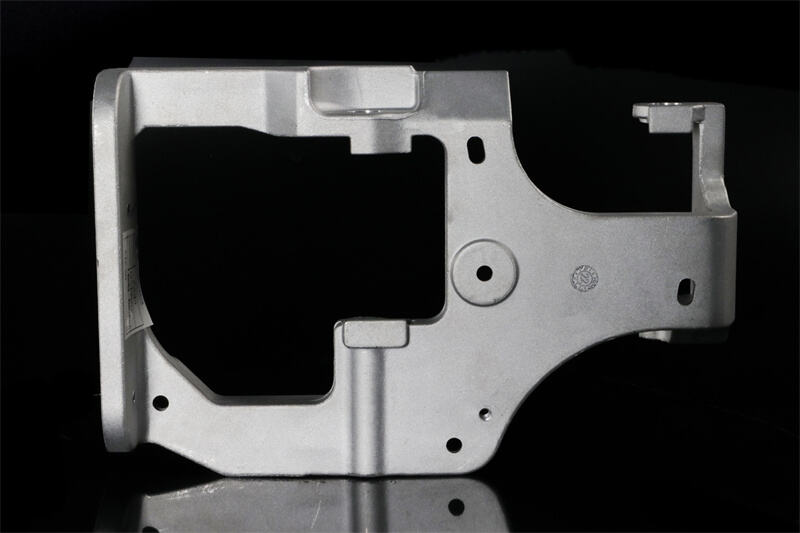

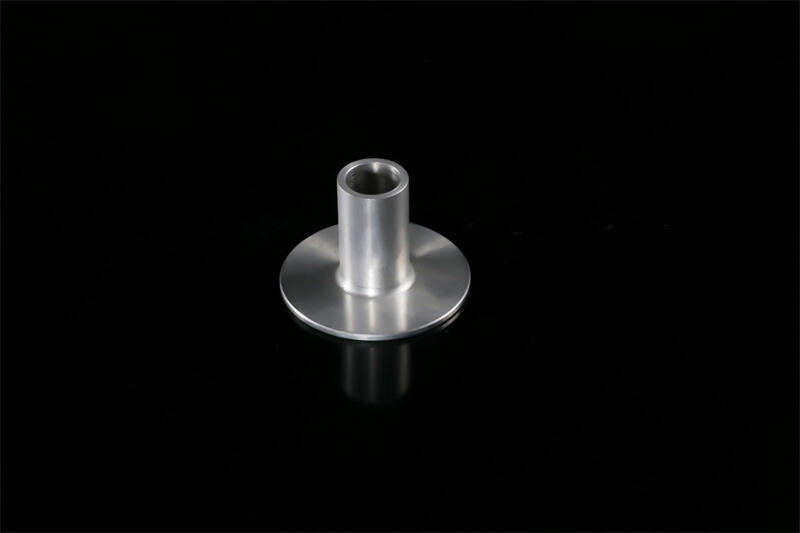

layout inspection

Ensure that the dimensional accuracy and specifications of each product meet the design requirements through exhaustive measurement verification.

05

Salt spray test

Artificially simulated salt spray environmental conditions for rapid assessment of material corrosion resistance Film thickness inspection is a critical step in measuring the thickness of a coating, plating or film to ensure uniformity and quality to safeguard the protection and durability of a product.

06

Film thickness detection

Film thickness inspection is a critical step in measuring the thickness of a coating, plating or film to ensure uniformity and quality to safeguard the protection and durability of a product. .

07

Buckling tests

Buckling tests are critical for assessing the stability of structures under compression, determining the critical load at which they become unstable, and ensuring structural safety against catastrophic failures.

08

Roughness Report

Our company offers precise roughness reporting, ensuring your parts' surface finish aligns with specification standards for optimal performance.

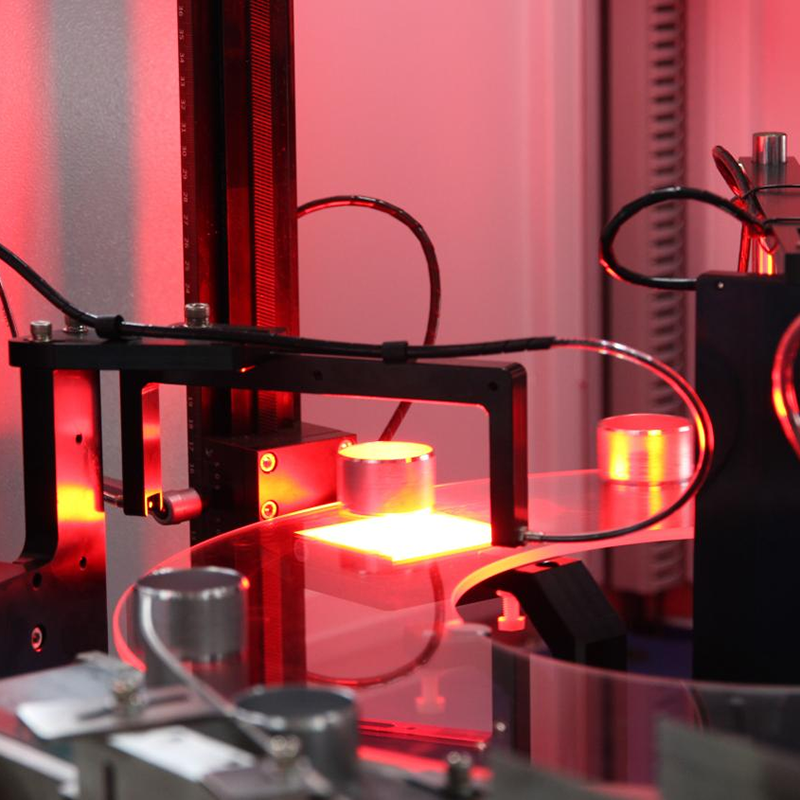

Infrared Dimensional Inspection

Infrared Dimensional Inspection

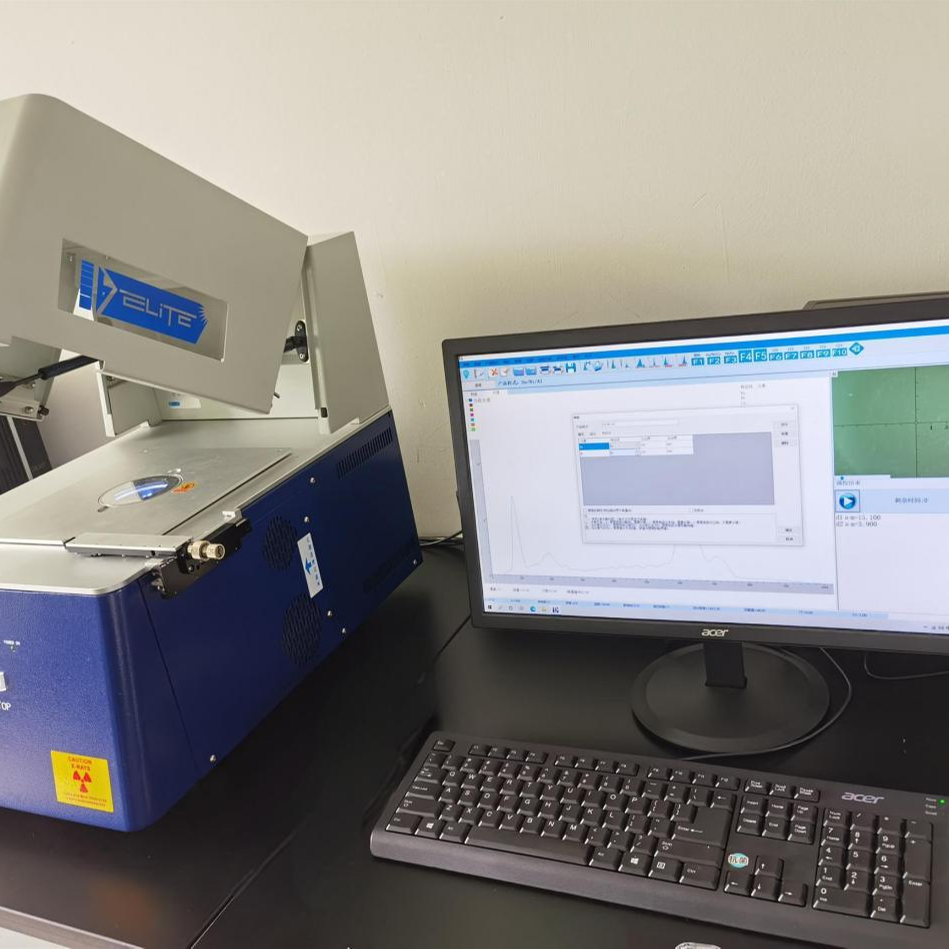

spectrograph

spectrograph

coordinate

coordinate

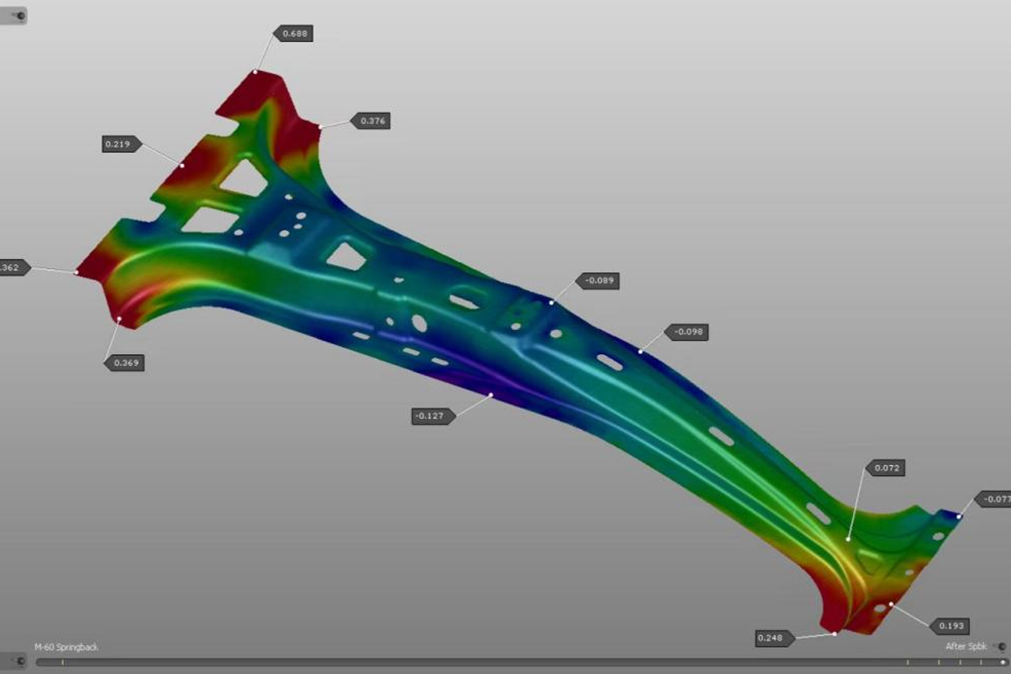

3D blue light scanner

3D blue light scanner

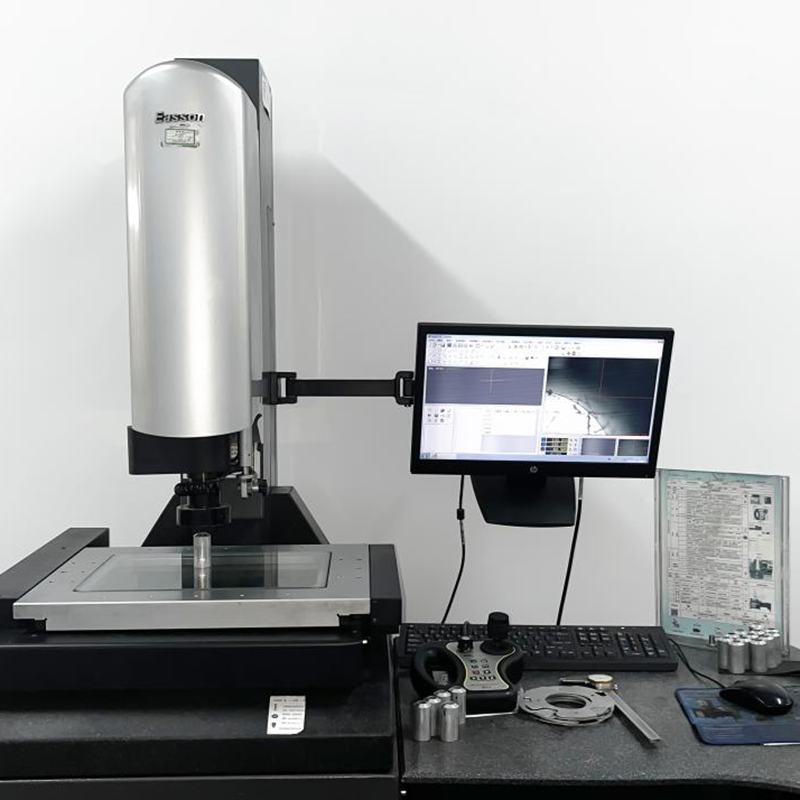

Measuring projector

Measuring projector

Mechanical Property Tester

Mechanical Property Tester

Hardness tester

Hardness tester

Film thickness tester

Film thickness tester