SHAOYl, as a leading supplier of automotive metal parts in China over the years, has won the trust of many customers in the automotive industry. Shaoyi has full rich experience in manufacturing metal or aluminum automotive cores, bushings, tubes etc., we are always committed to providing customers with high quality and efficient solutions ,sametime we continually meet the new challenges and innovative needs of the automotive industry.

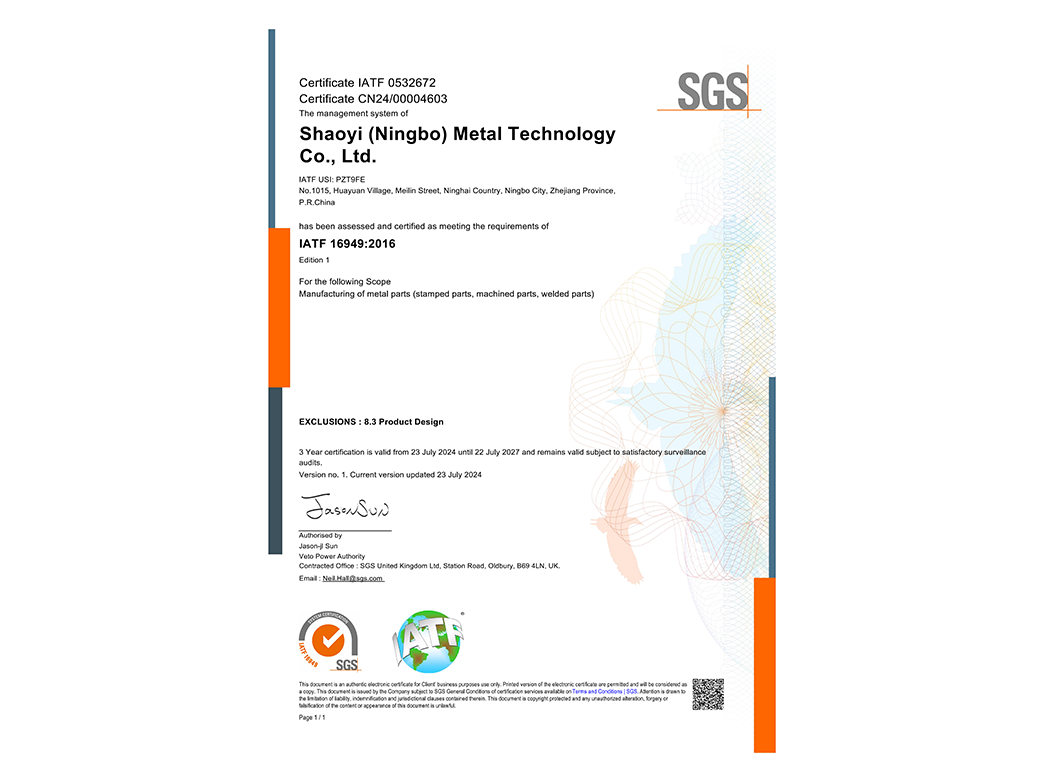

IATF TS16949:2016/Critical to Quality

Factory Area

R&D Engineer

Steel & Aluminum

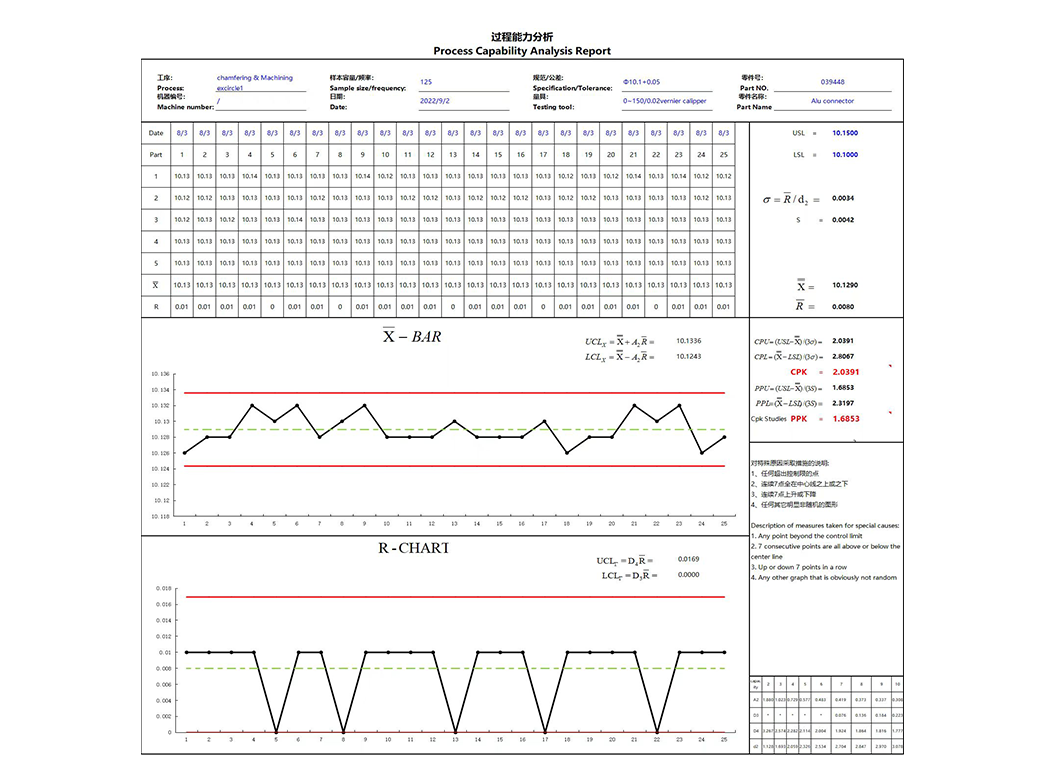

We use a variety of quality control methods to ensure that the products we deliver to our customers are of the right size and performance for their needs.

Our unwavering commitment to quality is bolstered by our IATF 16949 certification, ensuring a stringent quality control system throughout every phase of production. This certification is a testament to our meticulous approach, from the initial design to the final product delivery. -IATF16949 Certification

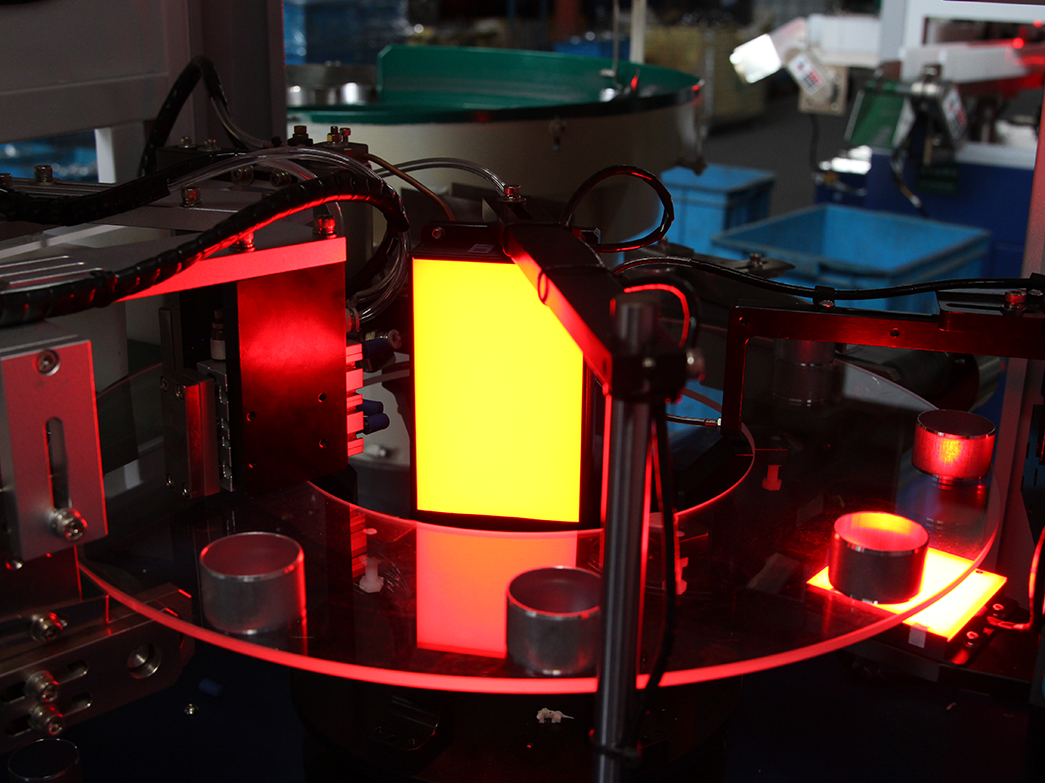

Leveraging top-tier production and inspection equipment, our state-of-the-art, fully automated machinery guarantees product quality with every manufacturing process, ensuring consistency and excellence in every output.

Our team of technical experts, each with over a decade of experience in metal fabrication, forms the backbone of our operations. These elite engineers bring a wealth of knowledge and expertise to every project, ensuring that our products not only meet but exceed industry standards for quality and innovation.

Metal bushings are essential components in automobiles, used for critical parts such as suspension systems, engine and transmission suspensions, steering systems, transmission systems, braking systems, body structures, and wheel bearings. These bushings significantly enhance the performance, durability, and driving comfort of automobiles by reducing friction, absorbing vibration, and providing stable connections.

We have 13 years of experience in manufacturing automotive metal components and have been certified to the IATF 16949 standard for many years

Our advanced metal processing facilities include state-of-the-art automated tube cutting machines, chamfering machines, and precision CNC lathes enable us to deliver specialized and high-quality metal tube processing services

We provide comprehensive tube customization services, tailoring specifications and varieties to suit your product's application. Our mature processes help you reduce overall costs while ensuring optimal performance

All our metal bushings and core products undergo thorough inspection using our infrared dimension measuring equipment. This ensures that every product meets the precise size requirements of our clients

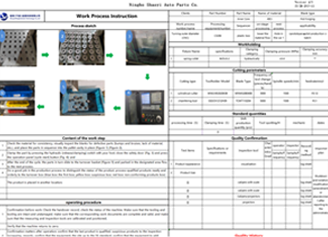

Standardized,process-oriented refined production standards efforts to provide you with up to 99.8%qualified string of precision parts

Pre-manufacturing feasibility assessment and optimization

Benchmarking,assembly,and inspection criteriadevelopment foridentification of key dimensions

For DFM and work instructions standard full-sizeinspection proofing process problems

Summarize the proofing problems, close the problerpointsand continuously optimize the productlon process

Determine the correctness of the manufacturing process and that the product meets the customer's specifications and process requirements.

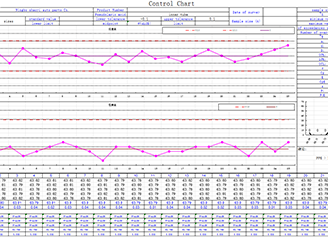

Control of special requirements and processesimplementation of CPK>l.33 for key dimensions

Perform according to AQC standards and requirements

Through precise data monitoring and process optimization, we ensure timely delivery of products.

| Processing Capabilities | Processing Capabilities | ||

| Steel | Steel:10#, 20#, 35#, 45#, S45C, 55#, Q235B, Q235C, Q345D, CF53, A105 | Production range | OD:10-120mm |

| Alloysteel:16Mn(Q345B), 20Cr40Cr, 15CrMo, 20CrMo, 28CrMo, 30CrMo, 35CrMo, 42CrMo, 4130, 4140, 20CrMnTi, 40MnMoV20Mn2.37Mn5, ZF6,16MnCr5, 20MnCr5, 36Mn2V, 38Mn2v, 20Mn2, 65Mn, 15Mo3, 34mnb5 | ID:1.2-20mm | ||

| Aluminum | 6082, 6061, 7075, 7050, 6061, 6063, 6082, 2024, 2a12, 5a06, 5a05, 5052, 5754, 5083 | Testing Equipment | Tensile Testing Machine, Rockwell Hardness Tester, Eddy Current Testing Equipment, Chemical Composition Analyzer, Magnetic Particle Inspection Equipment, Metallurgical Microscope, Surface Roughness Tester, Outside Micrometer, Wall Thickness Micrometer, Inside Dial Indicator, Vernier Caliper |

| Manufacturing Processes and Materials | Manufacturing Processes and Materials | ||

|---|---|---|---|

|

CNC Machining Materials |

Metals |

Pipe Processing

|

steel tube |

|

Cold Extrusion |

steel |

|

Our engineers ensures maximum productivity and cost efficiency for client projects.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.