Over the years, Shaoyi has established itself as a leading automotive cold heading supplier in China, earning the trust of countless industry clients. With extensive expertise in cold heading automotive components, we deliver high-performance, precision-engineered parts designed to meet the rigorous demands of the automotive sector. Our commitment to innovative, efficient cold heading solutions ensures every project achieves exceptional quality and reliability.

IATF TS16949:2016/Critical to Quality

Factory Area

R&D Engineer

Steel & Aluminum

We implement rigorous quality control protocols to ensure that every cold headed fastener consistently meets the exacting size and performance specifications demanded by our clients.

Our unwavering commitment to quality is bolstered by our IATF 16949 certification, which underpins a stringent quality control system throughout every phase of production. This certification reflects our meticulous approach to delivering superior cold heading services for automotive components—from initial design to final delivery—ensuring exceptional performance and reliability.

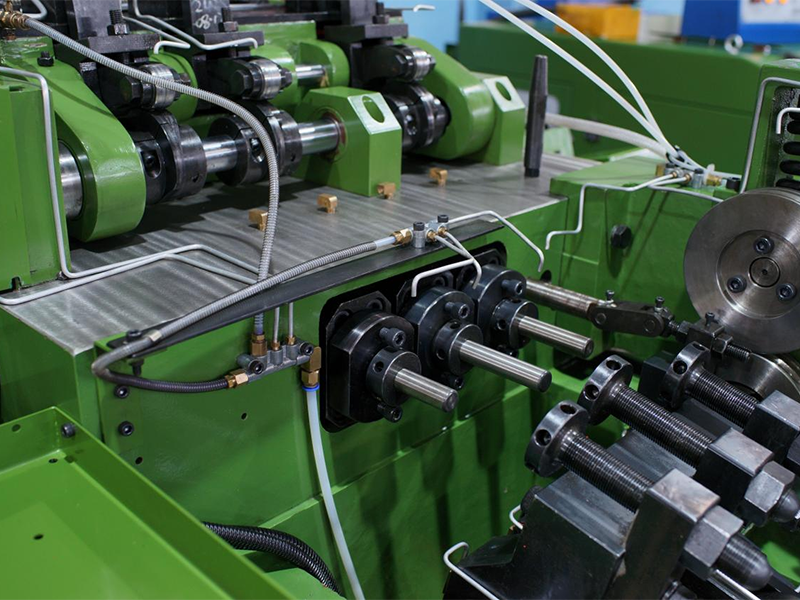

Leveraging top-tier production and inspection equipment, our state-of-the-art, fully automated machinery guarantees exceptional product quality at every stage of the cold heading process, ensuring consistency and excellence in every output.

Our team of technical experts, each with over a decade of experience in metal fabrication, forms the backbone of our operations. These elite engineers bring a wealth of knowledge and expertise to every project, ensuring that our cold heading services for automotive parts not only meet but exceed industry standards for quality and innovation.

With over 14 years of experience in cold heading parts manufacturing, we excel in producing precision-engineered components across a diverse range of applications—from automotive shock absorber series to CNC precision machining series and hydraulic alloy series. Our rich expertise enables us to optimize material usage, streamline production, and consistently deliver parts that meet the most stringent industry standards.

Located in Ninghai County, Ningbo—recognized as an automotive parts manufacturing base—our company benefits from a robust ecosystem of advanced automotive components and process support. With Ningbo’s efficient export port at our doorstep, we ensure seamless global logistics and a competitive edge in international markets.

With extensive experience in the automotive industry, we specialize in producing high-precision cold heading parts automotive, particularly for automobile chassis applications. Our expertise in manufacturing cold-headed components has made us a trusted partner for leading domestic automotive shock absorber companies.

Shaoyi is committed to providing top-notch service with 24-hour response times, quick quotes, and fast delivery. We focus on meeting every client's needs efficiently, ensuring high-quality results and timely project completion.

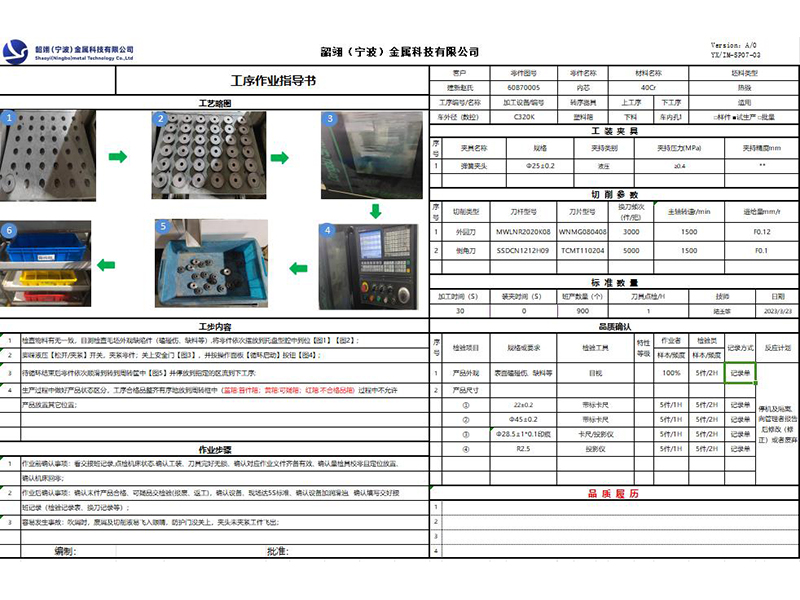

Standardized,process-oriented refined production standards efforts to provide you with up to 99.8%qualified string of precision parts

Pre-manufacturing feasibility assessment and optimization

Benchmarking,assembly,and inspection criteriadevelopment foridentification of key dimensions

For DFM and work instructions standard full-sizeinspection proofing process problems

Summarize the proofing problems, close the problerpointsand continuously optimize the productlon process

Determine the correctness of the manufacturing process and that the product meets the customer's specifications and process requirements.

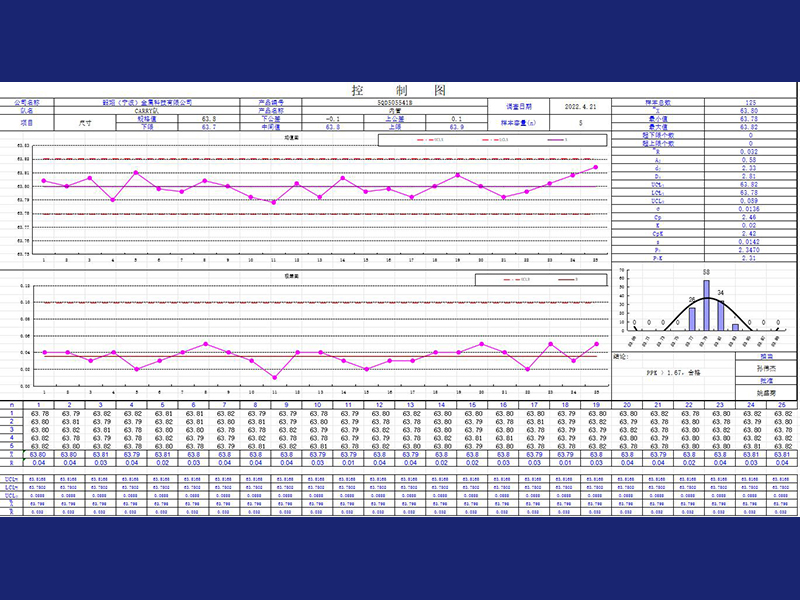

Control of special requirements and processesimplementation of CPK>l.33 for key dimensions

Perform according to FQC standards and requirements for car part stamping, ensuring precision and consistency throughout the production process.

Through precise data monitoring and process optimization, we ensure timely delivery of products.

| Wire Diameter Range | 2mm – 25mm (adjustable according to project needs) |

| Finished Part Length | 5mm – 150mm (depending on shape and requirements) |

| Applicable Materials | Carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy, brass, etc. |

| Dimensional Tolerances | ±0.02 – ±0.05mm (varies based on material and part complexity) |

| Quenching, tempering, carburizing, nitriding, etc. | |

| Surface Treatments | Black oxide, zinc plating, nickel plating, phosphating, passivation, etc. |

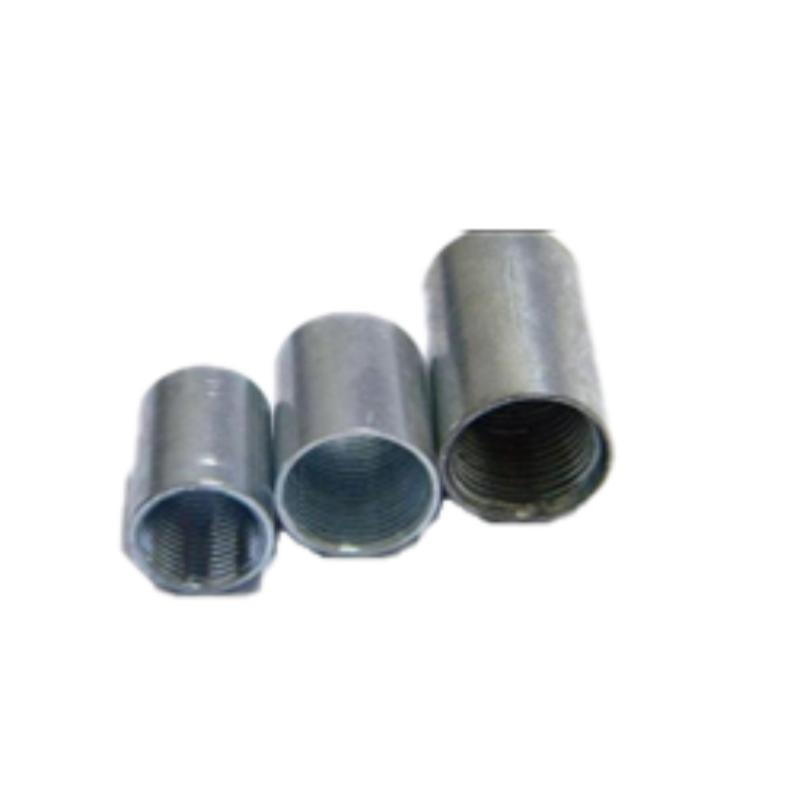

| Secondary Operations | Thread rolling, knurling, drilling, tapping, etc. |

| Production Volume | Accommodates both small batches and large-scale runs, with monthly output in the hundreds of thousands or more. |

| Industries Served | Automotive, machinery, electronics, hardware, and more. |

| Note | These parameters are for reference only and may vary depending on specific design and equipment. |

Focus on chassis welded assemblies, shock-absorbing welded assemblies, chassis stamping, and machining parts.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.