Exploring Aluminum Extrusions: 6061 and 6063 Applications in Automotive Manufacturing

Description:

Discover the distinct properties and applications of 6061 and 6063 aluminum alloys in automotive manufacturing. Learn how Shaoyi Company leverages these alloys to deliver custom solutions for lightweight and high-performance automotive parts.

Keywords:

aluminum extrusions for automotive, aluminium extrusion automotive, aluminum extrusion parts, extruded aluminum parts, aluminum extrusion plate, extruded aluminum chassis

Exploring Aluminum Extrusions: 6061 and 6063 Applications in Automotive Manufacturing

In modern manufacturing, particularly in the automotive industry, aluminum extrusions for automotive applications have gained significant traction. Alloys like 6061 and 6063 are leading the way due to their distinct properties, creating a wide range of aluminium extrusion automotive products. Let's delve into the characteristics and applications of these alloys.

1. 6061 Aluminum Alloy: Strength and Versatility

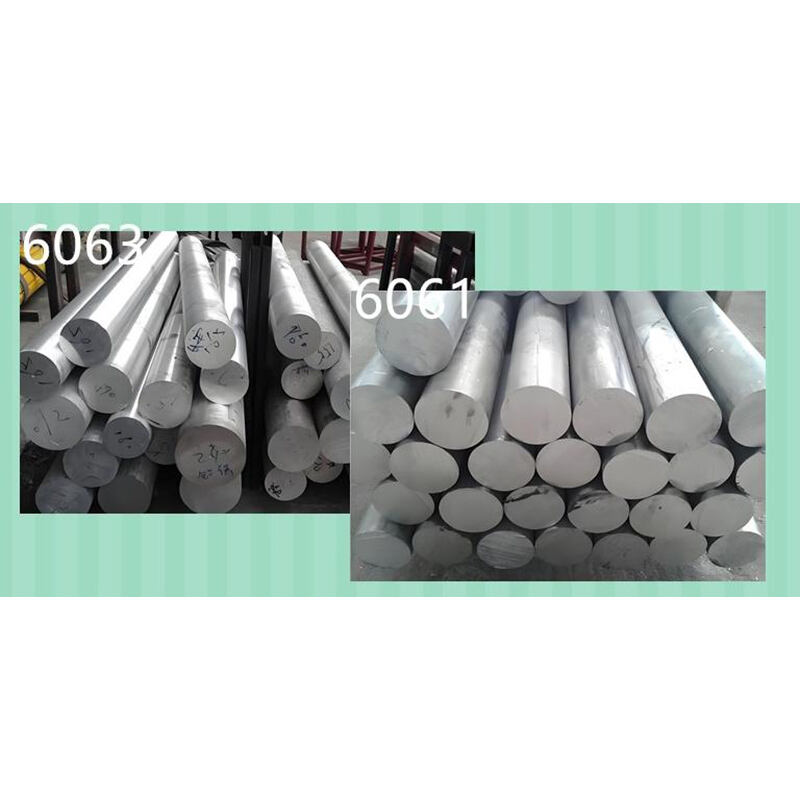

1.1 Chemical Composition and Basic Properties

6061 aluminum alloy, with magnesium and silicon as primary alloying elements, offers excellent processability, weldability, and corrosion resistance. This medium-strength alloy enhances strength through heat treatment, making it a popular choice for various aluminum extrusion parts in automotive manufacturing.

1.2 Applications in Automotive and Performance Benefits

For aluminum extrusions for automotive, 6061 is commonly used in chassis components such as extruded aluminum chassis parts. Its high strength ensures structural stability under vehicle weight and stress, ensuring safety. Additionally, its corrosion resistance protects against road water and salts, extending chassis life.

In manufacturing extruded aluminum parts around engines, 6061's processability allows for complex shapes to meet special design requirements.

2. 6063 Aluminum Alloy: Aesthetics and Formability

2.1 Chemical Composition and Performance Highlights

6063 aluminum alloy also uses magnesium and silicon but in lower quantities than 6061, resulting in superior surface treatment and extrusion formability. The extruded products feature smooth surfaces and uniform colors, ideal for applications where appearance matters.

2.2 Advantages in the Automotive Industry

In automotive interiors, 6063 is used for aluminum extrusion plate components. Its formability allows for complex and intricate shapes to meet diverse interior design needs. Surface treatment enhances durability and aesthetics, elevating interior quality.

For aluminium extrusion automotive products requiring high appearance and precision standards, 6063 is the preferred choice.

3. Custom Services and Customer Success Stories

3.1 Custom Services

Shaoyi Company specializes in aluminum extrusion processing services, offering custom solutions based on customer designs. Whether you need high-strength aluminum extrusions for automotive using 6061 or intricate interior parts using 6063, our expert team and advanced equipment ensure precise production according to your specifications.

3.2 Customer Collaboration Cases

Automaker A: Developed a lightweight aluminum extrusion chassis, improving fuel efficiency.

Construction Firm B: Produced high-precision curtain wall frames using 6063 aluminum extrusions, enhancing building aesthetics and durability.

Industrial Equipment Manufacturer C: Reduced production costs by 20% through optimized design, boosting market competitiveness.

4. Future Trends and Challenges

As electric vehicles and lightweight designs become more prevalent, demand for aluminum extrusions for automotive will continue to rise. Despite challenges like material costs and processing complexity, innovations and process improvements will allow 6061 and 6063 alloys to expand their applications in aluminum extrusion parts and extruded aluminum chassis.

5. Conclusion

Both 6061 and 6063 aluminum alloys are crucial in modern industry and automotive manufacturing. Selecting the right alloy enhances product performance, durability, and achieves lightweight and energy-saving goals.

Shaoyi Company is committed to providing high-quality custom aluminum extrusion services. For technical support or tailored solutions, contact our expert team! We look forward to collaborating with you to drive innovation in product design and manufacturing.