How Auto Stamping Parts Are Used in Vehicle Body and Chassis Production

In the automotive manufacturing industry, metal stamping automotive parts are integral to producing key components for vehicles. The process of stamping automotive parts involves applying pressure to a metal sheet to shape it into the desired form. This process is crucial for manufacturing components that contribute to the vehicle's structural integrity, safety, and overall performance. In this blog, we will explore how automotive stamping press technology is used in the production of vehicle body and chassis components.

The Role of Auto Stamping Parts in Vehicle Body and Chassis Production

When it comes to vehicle production, the automotive body and chassis are the foundational elements of any vehicle. These components must be lightweight yet durable to ensure the vehicle’s performance, safety, and fuel efficiency.

Stamping automotive parts are produced to meet the complex requirements of vehicle body and chassis production. Components such as door panels, fenders, and chassis frames are commonly produced using metal stamping services. The metal stamping parts produced in this process are shaped precisely to fit the vehicle's specifications.

metal stamping services

For example, the automotive stamping press is used to create essential body panels like quarter panels, roof panels, and bumpers, which serve both aesthetic and functional purposes. These parts need to meet stringent strength, durability, and dimensional accuracy standards.

Why Precision Matters in Auto Stamping for Body Panels

Precision is key in the production of body panels. The automotive stamping press enables manufacturers to create metal stamping parts with exact specifications, ensuring that body panels fit together perfectly. This precision is crucial for both the vehicle's structural integrity and visual appeal. Moreover, the accuracy in metal stamping automotive ensures that parts are produced at a high speed without compromising on quality.

Manufacture of stamping automotive

Advantages of Metal Stamping in Vehicle Body Production

One of the primary reasons metal stamping automotive parts are used in vehicle body production is the ability to produce high-precision components at a fast rate. Stamping parts manufacturers use advanced automotive stamping press machines to create parts with consistent quality, which is essential for mass vehicle production.

In addition, metal stamping parts offer the necessary strength while keeping the overall weight of the vehicle low. This balance is crucial for improving fuel efficiency and meeting environmental standards. Advanced automotive stamping press machines enable manufacturers to produce complex shapes, such as curved or contoured surfaces, with high precision and minimal waste.

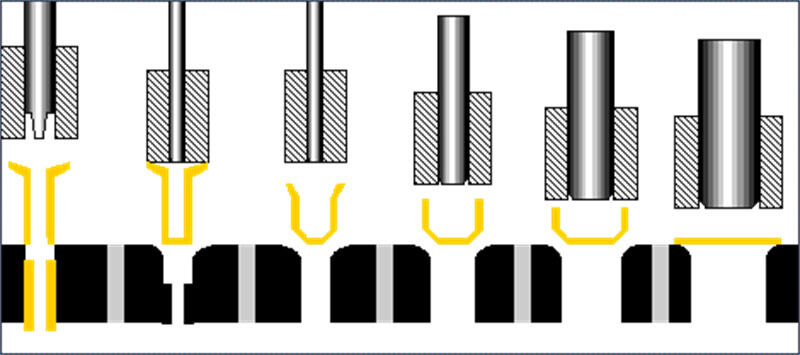

Rapid production of metal stamping dies

Cost-Effective Mass Production with Metal Stamping

Metal stamping services provide an efficient method for producing large quantities of parts quickly and cost-effectively. By using automotive stamping press technology, manufacturers can meet high-volume demands while maintaining high quality, which is essential for the competitive automotive industry.

Key Components Produced by Metal Stamping in Vehicle Chassis

In the production of vehicle chassis, stamping automotive parts are used to create structural components such as cross members, subframes, and suspension mounts. These parts are critical for ensuring the overall strength and rigidity of the vehicle.

Metal stamping services help stamping parts manufacturers produce large volumes of precision parts needed for chassis systems. Components like chassis rails and floor pans are typically produced using metal stamping parts due to their high-strength requirements and the need for cost-effective mass production.

The Role of Precision in Chassis Components

When producing chassis components, it is essential that the parts are both precise and durable. The automotive stamping press technology allows metal stamping automotive parts to meet the strict specifications required for structural components. This ensures the vehicle's overall strength and safety, making precision a vital aspect of the chassis production process.

Why Choose Metal Stamping Services for Automotive Production?

For stamping parts manufacturers, offering metal stamping services for automotive production brings numerous advantages. First and foremost, metal stamping is a highly efficient method for producing large quantities of parts quickly. This helps automotive manufacturers meet demanding production schedules while maintaining high standards of quality.

Additionally, the advanced automotive stamping press technology guarantees the production of high-quality parts with minimal defects. This is essential in the automotive industry, where components must adhere to strict safety and regulatory standards. Metal stamping services also reduce production costs while maintaining quality, enabling manufacturers to remain competitive.

Cost and Time Efficiency in Automotive Production

By utilizing metal stamping automotive technology, stamping parts manufacturers can achieve significant time and cost savings in the production of automotive parts. Whether it's for vehicle body or chassis components, metal stamping parts provide a reliable and efficient solution that meets the high standards of the automotive industry.

Conclusion: The Future of Metal Stamping in Automotive Manufacturing

As the automotive industry evolves, the demand for high-performance metal stamping automotive parts will continue to grow. The development of automotive stamping press technology will enable stamping parts manufacturers to produce more complex, high-strength components at lower costs. Whether for vehicle body or chassis, metal stamping parts will remain critical in automotive manufacturing.

As the industry moves toward more sustainable and lightweight vehicles, metal stamping services will play an increasingly important role in meeting these demands. By providing innovative solutions and high-quality production, metal stamping will continue to shape the future of automotive manufacturing.