How Automobile Sheet Metal Parts Transform Vehicle Manufacturing

In today’s fast-evolving automotive industry, automobile sheet metal parts are the foundation of vehicle body and chassis production. These components, created through advanced automotive metal work, not only enhance the structural integrity of vehicles but also contribute to their aesthetic appeal and efficiency. In this article, we explore how automobile sheet metal parts are used in production, the role of modern stamping processes, and why choosing the right automotive metal stamping suppliers is critical.

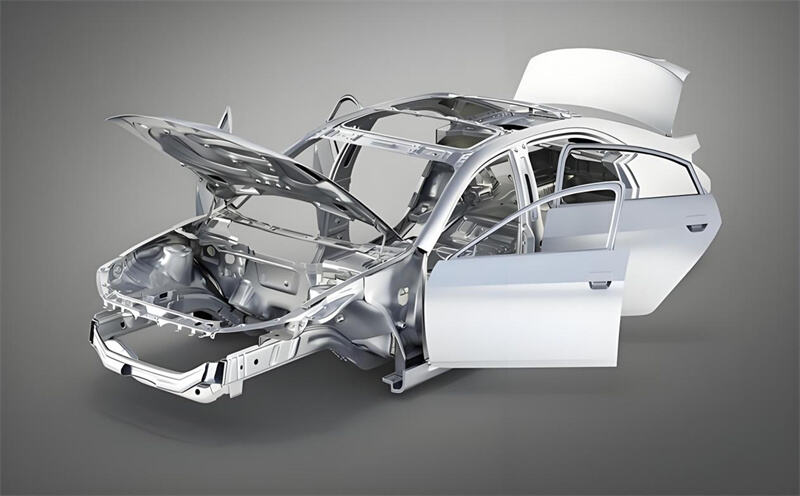

Introduction to Automobile Sheet Metal Parts

Automobile sheet metal parts are produced by cutting, stamping, and forming metal sheets into precise shapes. This process results in components such as doors, hoods, fenders, and structural chassis members. Advanced automotive metal work ensures that these parts meet stringent quality and safety standards.

Manufacturers rely on our expertise in providing high-quality metal stamping services. For more detailed information about our production capabilities, please visit our dedicated page on auto stamping parts.

Automobile sheet metal parts

The Role of Sheet Metal Parts in Vehicle Production

Key Functions in Vehicle Body and Chassis

The vehicle’s body and chassis are essential for safety, performance, and overall design.

· Vehicle Body: Comprises external panels that define a car’s appearance and protect its interior.

· Chassis: Provides structural strength and supports critical systems like the engine and suspension.

Automobile sheet metal parts are crucial in both areas. High-precision production using our advanced automotive metal work processes ensures that each component fits perfectly and contributes to overall vehicle performance. This high level of precision is achieved using modern automotive stamping press technology.

Impact on Quality and Performance

High-quality stamped parts contribute significantly to a vehicle’s performance:

· Structural Integrity: Precisely formed stamped metal parts provide robust support for the vehicle frame.

· Aesthetic Appeal: Uniform, smooth surfaces enhance the vehicle’s visual appeal.

· Efficiency: Lightweight and accurately produced components improve fuel efficiency and reduce emissions.

Manufacturers who prioritize advanced automotive metal work can ensure that every component meets the high standards expected in today’s competitive market.

Advantages of Advanced Automotive Metal Work

Enhanced Precision and Consistency

Modern manufacturing processes using high-end stamping equipment ensure that every automobile sheet metal part is produced to exact specifications.

· Precision: The use of computer-controlled stamping presses helps achieve consistent dimensions and high-quality stamped metal parts.

· Consistency: Repeated cycles with minimal variation guarantee uniformity across large production runs.

This level of precision is essential because even minor deviations can lead to assembly issues and compromise vehicle safety.

Efficiency and Cost-Effectiveness

The integration of modern automotive stamping press technology in automotive metal work leads to:

· Increased Productivity: Automated systems operate continuously, reducing production time.

· Material Savings: Precise stamping reduces waste, lowering overall manufacturing costs.

· Cost-Effectiveness: High-volume production of stamped parts ensures competitive pricing for vehicle manufacturers.

These advantages are crucial for steel stamping parts manufacturers and other partners who depend on high-quality production to maintain market competitiveness.

Automated automotive production plant

Flexibility in Design and Material Choice

Advancements in automotive metal work allow manufacturers to produce complex, custom shapes that meet evolving design requirements.

· Customization: Modern stamping dies enable the creation of unique, innovative designs.

· Material Versatility: Manufacturers can work with various materials, including high-strength steel and aluminum alloys, to produce durable yet lightweight automobile sheet metal parts.

This flexibility ensures that vehicle designs remain innovative while maintaining performance and safety standards.

Choosing the Right Automotive Metal Stamping Suppliers

What to Look for in a Supplier

For manufacturers, selecting reputable automotive metal stamping suppliers is critical. Consider the following criteria:

· Quality and Precision: The supplier should consistently produce top-quality stamped metal parts with minimal defects.

· Technological Capability: Advanced automotive stamping press systems and modern automotive metal work processes are a must.

· Industry Experience: Look for suppliers with a proven track record in the automotive sector.

· Cost Efficiency: Competitive pricing without compromising quality is key.

· Support and Reliability: Timely delivery and robust after-sales support are essential for long-term partnerships.

By focusing on these criteria, manufacturers can ensure that their parts are produced with the highest standards in mind.

Benefits of a Strong Supplier Partnership

A long-term relationship with reliable automotive metal stamping suppliers can provide numerous benefits:

· Enhanced Product Quality: A consistent supply of high-quality stamped parts reduces production downtime and improves the assembly process.

· Cost Savings: Efficient production processes and economies of scale lead to significant cost reductions.

· Innovation: Collaborating with experienced suppliers opens the door to adopting new technologies and innovative production methods.

For more insights into selecting the right supplier, please visit our internal resource on auto stamping parts.

Future Trends in Automotive Metal Work

Emphasis on Lightweight and Sustainable Solutions

The automotive industry is moving toward lighter and more sustainable designs. Automobile sheet metal parts made from advanced materials like aluminum are gaining traction.

· Lightweight Design: Reducing vehicle weight improves fuel efficiency and lowers emissions.

· Sustainability: Eco-friendly production methods and recyclable materials are becoming industry standards.

These trends are reshaping automotive metal work and influencing how stamped metal parts are produced.

Integration of Digital Technologies

The future of automotive metal stamping suppliers is being defined by digital advancements:

· Automation and IoT: Enhanced process control through connected machinery and real-time data analysis.

· Artificial Intelligence: AI-driven optimization of production processes to achieve even higher levels of precision.

· Predictive Maintenance: Reducing downtime by anticipating equipment issues before they impact production.

Such technologies ensure that automobile sheet metal parts are produced faster, with even greater accuracy, and with reduced environmental impact.

Smart Factory Digitalization Screen

Market Outlook for Stamped Parts

The market for stamped parts is expected to grow as demand increases for high-quality, precision components in the automotive sector. Manufacturers and steel stamping parts manufacturers alike are investing in advanced automotive metal work technologies to meet these demands. As competition intensifies, suppliers who can deliver consistent, cost-effective stamped metal parts will lead the industry.

Conclusion

Automobile sheet metal parts are at the heart of modern vehicle manufacturing. They ensure that the vehicle body and chassis meet rigorous quality and safety standards. Advanced automotive metal work techniques, powered by state-of-the-art automotive stamping press systems, enable the production of high-quality, cost-effective stamped parts.

For automotive manufacturers, partnering with reliable automotive metal stamping suppliers is crucial for long-term success. As the industry moves toward more sustainable and lightweight vehicles, the role of automobile sheet metal parts will become even more significant.

The future of automotive manufacturing is bright, with ongoing advancements in technology and process optimization. By embracing these trends and investing in modern production processes, companies can maintain a competitive edge in the ever-evolving automotive market.

For further insights into automotive manufacturing trends and advanced production methods, please visit our auto stamping parts page.