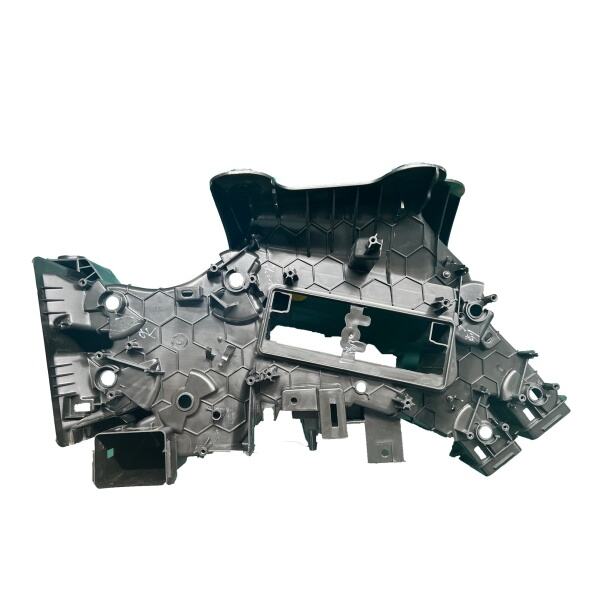

Hai! Sila teruskan membaca untuk mendapatkan sedikit gambaran tentang bagaimana kami membuat cebisan kereta dari plastik. Proses ini dikenali sebagai pengebapan plastik. Itu agak hebat walaupun Shaoyi mould automotif hanya meleburkan plastik, memanaskannya hingga suhu di mana ia boleh dibentuk dan kemudian membentuknya kepada cebisan yang membina kereta. Betapa hebatnya itu untuk dipertimbangkan? Cebisan sebuah kereta terdiri daripada ratusan elemen dan hari ini, salah satu daripadanya dihasilkan menggunakan pengebapan plastik.

Maka kita akan melangkah kepada butiran tentang pemodelan plastik melalui penyuntikan, apa sebenarnya ia bermaksud? Ia adalah cara untuk menghasilkan cetakan daripada plastik cair yang dilebur. Cetakan itu adalah jenis kasing yang boleh mengambil bentuk bahan plastik yang akan digunakan. Kita capai ini dengan membiarkan plastik cair panas tersebut dingin setelah kita telah menuangkannya ke dalam mould. Plastik itu selepas didinginkan menjadi kukuh dan boleh digunakan semula sebagai sebahagian daripada kereta. Kaedah ini sama baiknya dengan membuat bahagian kereta dan boleh dilakukan dengan lebih pantas dan mudah dalam beberapa jam!

Tetapi contohnya ketika kami menghasilkan bahagian kereta, sangat penting bahawa elemen-elemen kereta itu disambungkan dengan tepat. Jika salah satu elemen DFD adalah besar, yang lain akan terlalu besar untuk muat masuk atau terlalu kecil untuk memasukkan elemen besar itu. Ini bermakna kami HARUS menjadi sangat tepat! Setiap cetakan yang dihasilkan mesti memenuhi kehendak tersebut setiap kali. Kadang-kadang ini tidak mudah, namun, di Shaoyi kami mempunyai sumber dan tenaga kerja untuk melaksanakannya setiap kali. Kami percaya kepada membuat segala sesuatu muat dengan lancar pada tempatnya, seperti setiap kepingan muat dengan sempurna seperti teka-teki!

Pengecasan plastik, seperti semua aspek lain di dunia, adalah teknologi dan proses pembuatan yang berkembang. Seperti mainan/permainan yang diproduksi dan diluncurkan ke pasaran secara berkala, produk baru untuk pengecasan dikembangkan setiap hari. Terdapat juga bukti yang terdokumentasi dengan baik bahwa mesin-mesin kita menjadi semakin pintar setiap hari. Oleh karena itu, di Shaoyi, kami terus melakukan eksperimen dan menyempurnakan Shaoyi automotive die . Kami menggunakan proses dan bahan produk terbaik, yang memungkinkan kami membuat komponen yang berkualitas dan aman.

Plastik boleh menjadi lebih kompleks apabila datang kepada reka bentuk bahagian kereta. Ia mungkin penuh dengan rintangan yang perlu kita luputkan dalam proses menyelesaikan kerja. Kita juga perlu memeriksa bahawa plastik berada pada suhu yang tepat sebelum ia dituang ke dalam cetakan. Walau bagaimanapun, ini mungkin tidak berjaya jika air terlalu panas atau terlalu sejuk. Kita juga perlu mengawasi gelembung udara dalam cetakan kerana mereka menyebabkan lebih banyak masalah di kemudian hari. Tapi jangan risau! Untuk cabaran yang kita hadapi, Shaoyi mempunyai pasukan senior profesional yang faham bagaimana menangani cabaran untuk organisasi. Ia telah bersetuju bahawa kita menyelesaikan masalah bersama dan membuat segalanya berjalan se lancar mungkin.

Nah, tiada keraguan bahawa pengebapan plastik adalah salah satu cara terbaik untuk membuat cebisan kereta yang luar biasa, tetapi soalan dalam kes kita adalah bagaimana. Bahagian terbaiknya ialah di situlah semua keajaiban kopi berlaku sebagai akibat daripada menggiling melalui semua kerja yang membosankan. Dan apabila kita membina cebisan untuk kenderaan, mereka hanya jatuh pada tempat masing-masing seperti yang sepatutnya. Shaoyi pengebapan cebisan automotif membolehkan kereta beroperasi seperti yang dijangka dan memastikan semua orang di dalamnya dilindungi ketika menggunakan ia.

Syarikat kami berspecial dalam pengeluaran kenderaan, dengan lebih daripada 90 peratus produk kami tertumpu pada industri automotif. Kami menyediakan komponen berkualiti tinggi untuk pelbagai jenis kenderaan, termasuk kereta penumpang, kenderaan komersial, kereta golf serta motosikal, lori dan traktor. Portfolio produk yang luas ini menunjukkan keyakinan dan dedikasi kami untuk memenuhi keperluan pelbagai pasaran automotif. Selain itu, kami berasa bangga menjadi pembekal sistem suspensi teratas kepada Volkswagen di China, yang menunjukkan kemampuan kami untuk memberi penyelesaian yang boleh dipercayai dan inovatif kepada jenama automotif utama. Pengalaman perindustrian yang luas kami menjadikan produk kami tidak hanya memenuhi tetapi melampaui harapan pelanggan terhadap prestasi dan kualiti.

Kami sangat bangga memegang sijil IATF 16949, yang merupakan bukti kepada kecemerlangan pengurusan kualiti kami yang berusaha untuk dicapai dalam industri kereta. Jabatan kualiti kami memiliki penguasaan terhadap lima alat kualiti penting yang merangkumi Kawalan Proses Statistik (SPC), Analisis Sistem Pengukuran (MSA), Analisis Mod dan Kesannya Kegagalan (FMEA), Perancangan Kualiti Produk Terlebih Dahulu dan Proses Penyemakan Bahagian Pengeluaran. Selain itu, kakitangan kualiti kami telah menamatkan latihan Six Sigma yang meluas, memastikan bahawa kami mematuhi piawai kualiti produk yang paling ketat. Kaedah kawalan kualiti yang menyeluruh ini memastikan setiap produk yang kami sediakan tidak hanya memenuhi tetapi sering melebihi harapan industri, tetapi juga memberikan keyakinan dan kepuasan kepada pelanggan kami terhadap perkhidmatan kami.

Dengan lebih daripada 15 tahun pengalaman dalam sektor automotif, syarikat kami menawani kawasan lebih daripada 10,000 meter persegi dan berspecial dalam pengeluaran bahagian logam untuk lebih daripada 30 jenama automotif. Kami menggunakan teknik pemprosesan terkini yang termasuk perosakan, mesin CNC, pembuatan mold, dan pengecasan die aluminium untuk memastikan setiap produk adalah kepada piawai kualiti tertinggi. Prosedur kawalan kualiti ketat kami memastikan produk-produk kami adalah selalu dalam aspek dimensi, bentuk, dan prestasi. Ini mencipta keyakinan dan kepercayaan di kalangan pelanggan kami.

Kami bangga dengan bahagian R&D yang berdedikasi, di mana setiap jurutera mempunyai lebih 10 tahun pengalaman dalam bidang automotif. Kepakaran ini membolehkan kami untuk memahami ciri-ciri unik dan proses bahan yang pelbagai, membenarkan kami menyediakan penyelesaian yang disesuaikan untuk pelanggan kami. Kami menawarkan analisis CAE profesional, pembangunan produk dan sokongan teknikal bersama dengan laporan DFM terperinci untuk memastikan setiap aspek reka bentuk dioptimumkan untuk pengeluaran. Kami berdedikasi untuk meningkatkan teknologi dan menawarkan bahagian logam berkualiti tinggi yang memenuhi keperluan spesifik pelanggan kami.