Kako naše svarne skupine avtomobilskega okvirja zagotavljajo varnost in izvedbo vozil

V avtomobilski industriji ni mogoče preučiti pomena avtomobilskega okvirja in tehnike karoserije. Ti komponenti tvorijo osnovno hrbet vsakega vozila, zagotavljajočega tako njegovo varnost kot tudi izvedbo. V podjetju Shaoyi Metal Technology Co. se specializiramo v proizvodnji delov okvirja za avtomobile z uporabo naprednih svarniških skupin, da zagotovimo, da vsako vozilo izpolnjuje najvišje standarde varnosti, hkrati pa ohranja odlično izvajanje.

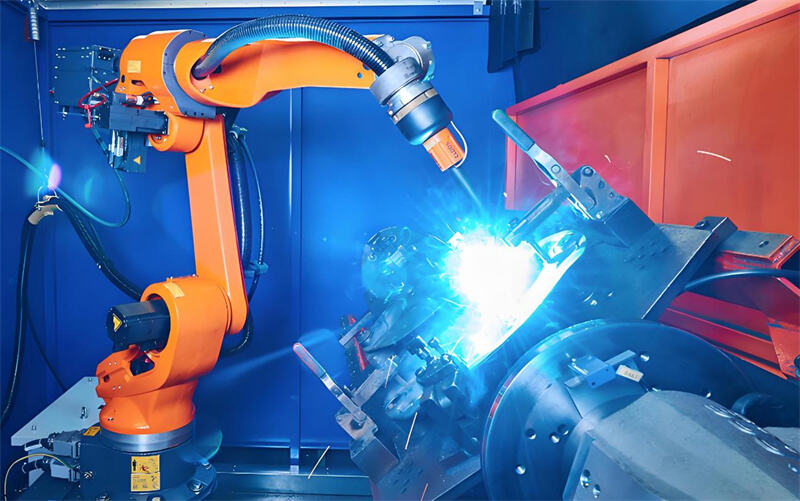

Robotska svarna vrsta

Vloga svarniških skupin okvirja pri varnosti vozil

Inženiring avtomobilskega podvozja in karoserije je ključnega pomena za ohranjanje strukturne celovitosti vozila med udarom. Komponente podvojja, vključno s komponentami spodnjega dela podvojja in zavesi za namestitev podvojja, so varsane skupaj, da se ustvari močna ogrodja, ki zaščita prevožence v primeru nesreče. Naše točne varseni tehnike zagotavljajo, da so ti deli varno povezani, ponujajoč neprimerljivo moč in stabilnost.

Zakaj so varsni montaže ključnega pomena za varnost

Varsenje je postopek, ki omogoča, da se posamezne komponente podvojja spoji z visoko točnostjo. Rezultat je brezvezna integracija delov podvojja, ki prispeva k sposobnosti vozila absorbirati in razporediti energijo med nesrečo. S uporabo naprednih metod varsenja zagotavljamo, da vsak del izvaja svojo namenjeno vlogo, ne da bi škodoval celotni varnosti vozila.

Tocno svarjevanje: Poskrbi za to, da je vsako svarje točno in zaklenjeno, kar je ključno za ohranjanje moči avtomobilskega nosilca in tehnike karoserije. Edino slabše svarje lahko povzroči pomembno strukturno napako med udarom, vendar s strogi kakovostni nadzor ta tveganja zmanjšamo.

Pohitrena izvedba: Svarljive skupine poskrbijo za enakost komponent nosilca po celotni proizvodni vrsti, kar je ključno za proizvodnjo velikih količin vozil brez kompromisov v varnosti.

svarjeni nosilci

Kako svarjevanje nosilcev vpliva na delovanje vozila

Delovanje je še ena območja, kjer igra avtomobilsko nosilčno in karoserijsko inženirstvo ključno vlogo. Moč svarjenega sestavka neposredno vpliva na ravnanje, trajnost in splošno voželjsko izkušnjo vozila.

Povečanje trajnosti vozil

Delovi karoserije avtomobila so izpostavljeni ekstremnim pogojev, vključno s toploto, vibracijami in napetostmi med običajnim vožnjem. Plošče za montažo karoserije in deli spodnje strane karoserije morajo biti svarovani z natančnostjo, da premočijo te sile in zagotovijo dolgotrajno trajnost.

Optimizacija vožnje vozil

Strojni integritet karoserije vpliva tudi na to, kako vozilo ravna pri različnih voznih pogojev. Dobro svarovana avtomobilska karoserija zagotavlja, da so vsi komponenti pravilno poravnani, kar omogoča gladko vožnjo in boljše drsenje na cesti.

Naša strokovnost v svarovanju skupin delov karoserije

V podjetju Shaoyi Metal Technology Co. razumemo podrobnosti inženiringa avtomobilske karoserije in telov. Naša specializirana strokovnost v svarovanju skupin delov zagotavlja, da je vsak del karoserije izdelan z najvišjimi standardi v mislih, tako da se zagotovi varnost in zmogljivost.

Zakaj nas izbrati za svoje potrebe po svarovanju avtomobilske karoserije?

- Najnovejša tehnologija: Uporabljamo najnovejše tehnične metode varske, da zagotovimo natančne in močne sestavine za vse delove kozin avtomobilov.

- Iskusan delovni sila: Naši tehnično izkušeni strokovnjaki imajo leta izkušenj z varsijo komponent kozin avtomobilov, kar zagotavlja najboljšo kakovost vaših vozil.

- Zavezanost kakovosti: Vsak del pod kozino in vsak nosilni zavihek je strogo preizbran glede na trajnost in moč.

Zaključek: Močna osnova za varnost in zmogljivost vozil

V zaključku, inženiring kozin in karoserije avtomobila je v srcu načrta vsakega vozila, in varske sestavine so ključne za zagotavljanje varnosti in zmogljivosti. Z izbiro Shaoyi Metal Technology Co. za dele kozin vaših avtomobilov investirate v natančnost, trajnost in zanesljivost. Naša strokovnost v varsiji zagotavlja, da so vaša vozila zgrajena tako, da bodo trajala dolgo, z močjo, ki jo potrebujejo za posredovanje katerega koli izziva na cesti.

Za več informacij o naših rešitvah za avtomobilsko kozino obiščite naš stran delov okvirja avtomobila .

Ključne besede: deli okvirja avtomobila, inženiring avtomobilskega okvirja in karoserije, komponente okvirja, deli pod okvirem avtomobila, nosilci za montažo okvirja

Majhne serije, visoki standardi. Naša storitev hitrega prototipiranja omogoča hitrejšo in enostavnejšo validacijo —

Majhne serije, visoki standardi. Naša storitev hitrega prototipiranja omogoča hitrejšo in enostavnejšo validacijo —