Hey there! Please continue reading to get a little insight on how we make car parts from plastic. This procedure is called as plastic injection moulding. That is however pretty cool though as Shaoyi automotive moulds is just melting the plastic, heating it to a temperature where it can be shaped and then just molding into those pieces that make cars. How awesome is that to consider? The parts of a car consist of hundreds of elements and nowadays using plastic injection moulding one of them is produced.

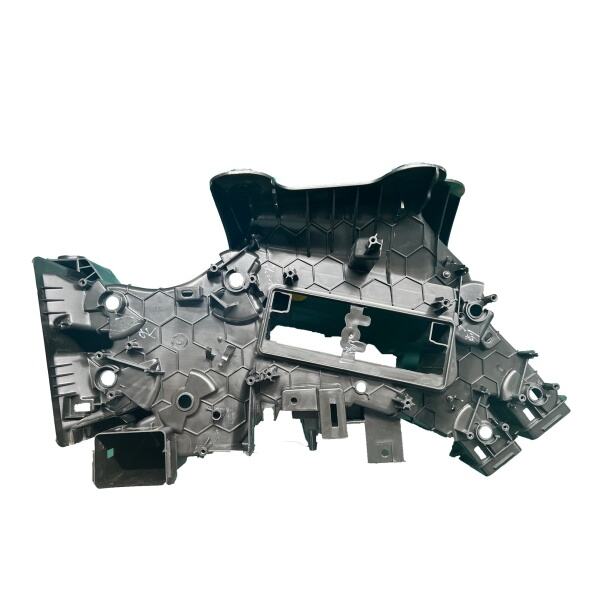

Thus we shall proceed to the details of the plastic injection moulding what really is it all about? It is how to produce the mold from the melted plastic. The mold is exactly a type of casing that can take the shape of the plastic material that will be used. This we achieve by letting the hot melted plastic to cool after we have poured it into the mould. The plastic after cooling becomes firm and can be reused as a certain part of car. This way is as good as making car parts and faster and simpler can be done in few hours!

But for example when we produce car parts it is very important that elements of the car are accurately assembled. If one of the DFD elements is large, the other one will be too large to fit it in or small to fit the large element in. Which means we HAVE to be super accurate! Each mould that is manufactured needs to match those requirements every single time. Sometimes it’s not simple, however, at Shaoyi we have the resources and manpower to execute that every time. We believe in making everything fit seamlessly into place, like each piece fitting a puzzle!

Plastic injection molding, just like all other aspects in the globe, is a growing technology and manufacturing process. Just as with toys/games that are manufactured and launched into the market on a regular bases, new products for molding are being developed everyday. There is also well documented evidence that our machines are even becoming smarter by the day. As a result here at Shaoyi we keep on experimenting and refining the Shaoyi automotive die. We use best process and product material, which will enable us to erect quality and safe parts.

Plastic can become even more complicated when it comes to designing car parts. It could be full of obstacles which we could have to jump over in the process of accomplish of the work. We also have to check that the plastic is at exactly the right temperature before it is then poured into the mold. This may however not work if the water is too hot or too cold We will also have to monitor the air bubbles in the mold because they cause more problems down the line. But don’t worry! For the challenges we encounter, Shaoyi has a professional senior team who understand how to tackle the challenge for the organization. It is agreed that we tackle the problems together and make everything go as smooth as possible.

Well there is no doubt that plastic injection moulding is one of the best ways to make awesome car parts, but the question in our case is how. The best part is that one, that’s where all the coffee magic happens as a consequence of grinding through all the tedious work. And when we construct parts for automobiles well, they simply falling into each other into place as they should. Shaoyi automotive parts molding makes the car to operate as expected and ensure all persons inside are protected when using it.

Our company specializes in automotive manufacturing, with over 90 percent of our products focused on the automotive industry. We provide high-quality components for a wide range of vehicles, including passenger cars, commercial vehicles, golf carts as well as motorcycles, trucks and tractors. This extensive product portfolio illustrates our versatility and commitment to meet the diverse needs of the automobile market. Furthermore, we are proud to be the top supplier of suspension systems to Volkswagen in China that demonstrates our capacity to offer reliable and revolutionary solutions to major automotive brands. Our vast industrial experience makes our products not only meet but exceed customer expectations for the performance and quality.

We are incredibly proud to hold the IATF certification 16949, which is a testament to our quality management excellence that we strive to achieve within the auto industry. Our quality department has mastery over five crucial quality tools which include Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and the Production Part Approval Process. Furthermore, our quality staff has completed extensive Six Sigma training, ensuring that we are adhering to the most stringent standards for quality of products. This comprehensive method of quality control ensures that every product we provide not only meets but often exceeds expectations of the industry, but also provides our clients with confidence and satisfaction over our services.

With more than 15 years of expertise in the automotive sector, our firm covers an area over 10,000 square meters and specialize in the manufacturing of metal parts for over 30 automotive brands. We utilize advanced processing techniques which include stamping, CNC machine machining, mold making, and aluminum die-casting to ensure that every product is of the highest quality standards. Our stringent quality control procedures ensure that our products are constant in terms of dimensions shape, form and performance. This creates confidence and trust with our customers.

We are proud of our dedicated R&D department, where every engineer has over 10 years of experience in automotive. This expertise enables us to understand the unique features and processes of various materials, allowing us to tailor solutions for our customers. We offer professional CAE analysis, product development and technical support along with detailed DFM reports to ensure that every aspect of the design is optimized for production. We're committed to advancing technology and offer high-quality metal parts that meet the specific needs of our customers.