As a leader in the field of custom automotive stamping mold manufacturing, we relentlessly pursue technological excellence and innovation. At Shaoyi, high-quality finished products are the result of professional design and manufacturing. Our mold design and project engineers are highly skilled and experienced, manufacturing all molds in-house using CAE simulation analysis and state-of-the-art equipment. We are able to ensure that the production of automotive stamping molds meets manufacturing requirements as well as customer-required finished product specifications and fast and timely delivery, so you can be sure that we will provide you with the best automotive stamping mold services.

IATF TS16949:2016/Critical to Quality

Factory Area

R&D Engineer

Steel & Aluminum

We use a variety of quality control methods to ensure that the products we deliver to our customers are of the right size and performance for their needs.

Our unwavering commitment to quality is bolstered by our IATF 16949 certification, ensuring a stringent quality control system throughout every phase of production. This certification is a testament to our meticulous approach, from the initial design to the final product delivery. -IATF16949 Certification

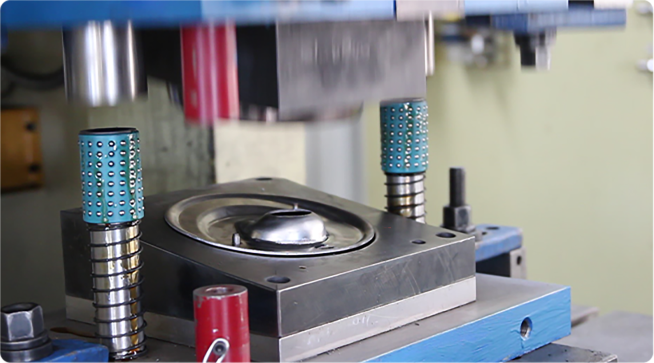

Leveraging top-tier production and inspection equipment, our state-of-the-art, fully automated machinery guarantees product quality with every manufacturing process, ensuring consistency and excellence in every output.

Our team of technical experts, each with over a decade of experience in metal fabrication, forms the backbone of our operations. These elite engineers bring a wealth of knowledge and expertise to every project, ensuring that our products not only meet but exceed industry standards for quality and innovation.

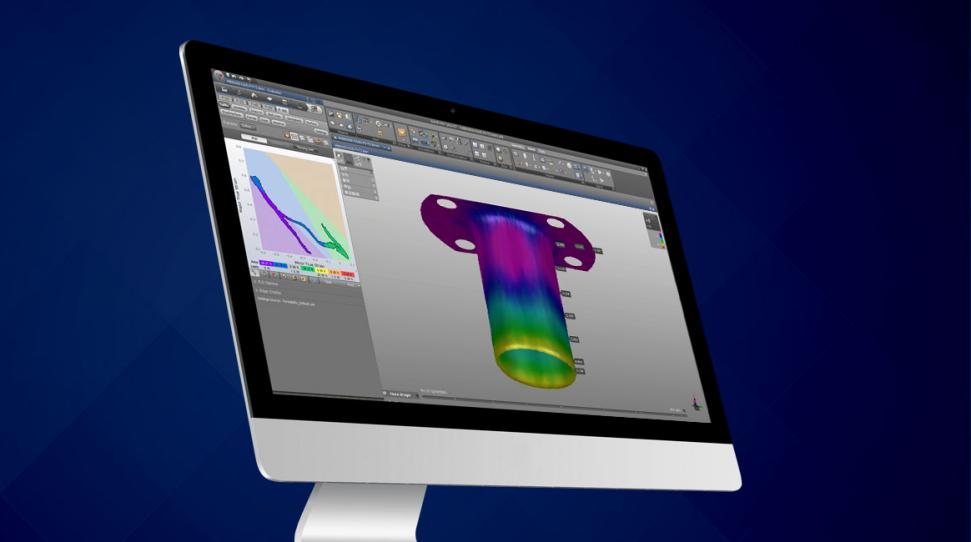

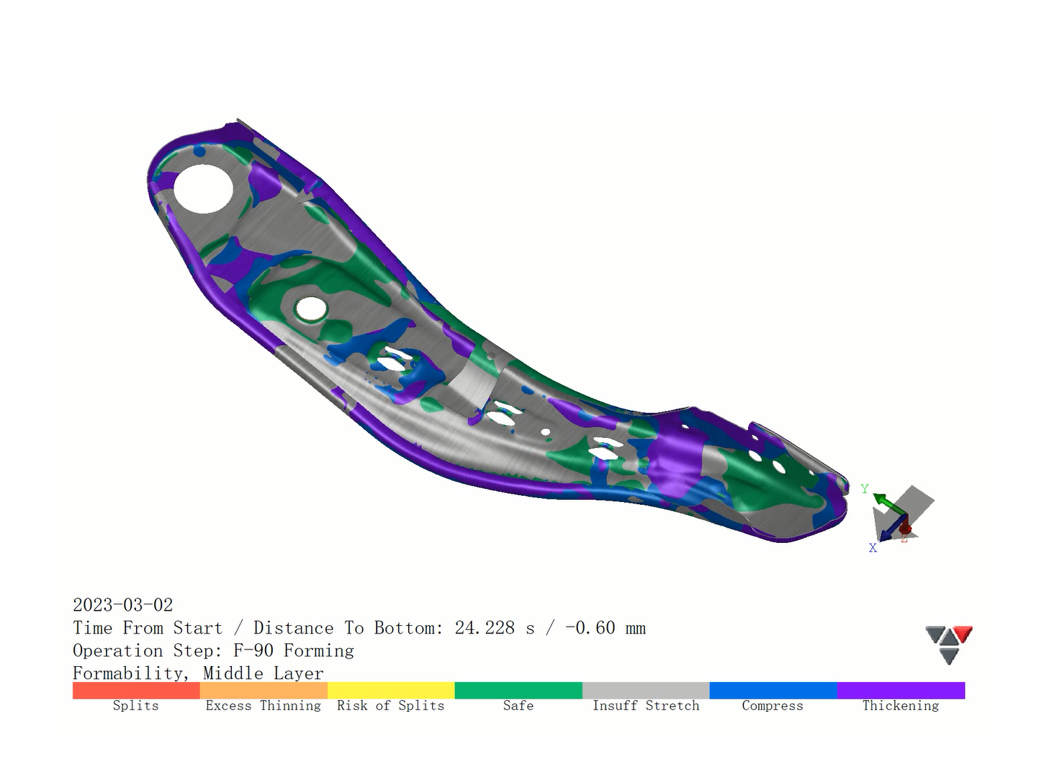

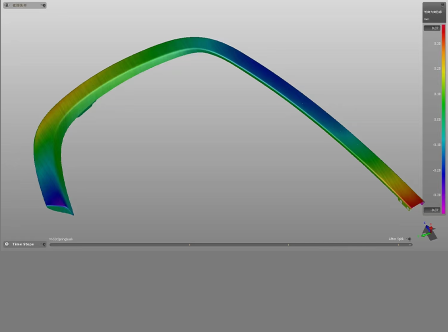

Have you ever pondered the challenges faced in the metal stamping parts industry, especially when dealing with high-strength steel materials boasting yield strengths exceeding 600 MPa? Overcoming rebound issues can indeed be a formidable task! However, we are steadfast in our commitment to finding solutions. This is precisely why we continue to conduct research on the springback phenomenon in stamped parts. Are you curious about the factors influencing the rebound of metal stamping parts for automobiles? Look no further! Our editorial provides insightful information to address your inquiries.

Contact Us

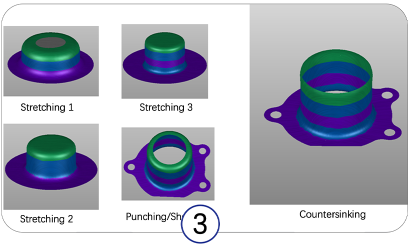

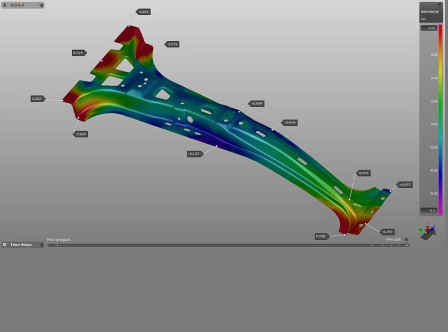

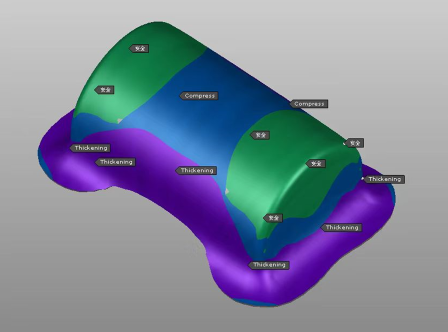

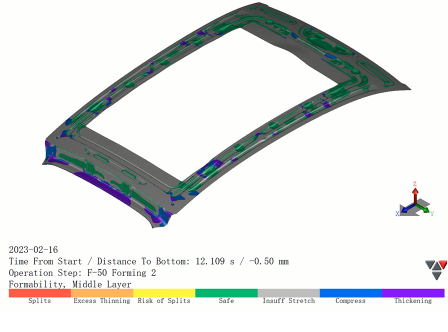

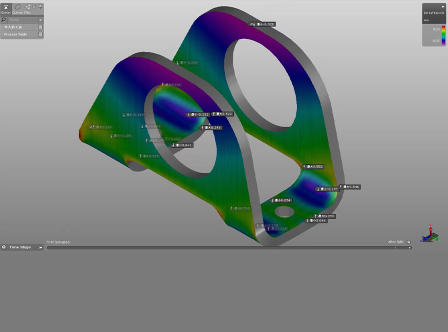

The technical team will use CAE analysis in the early stage to provide mold solutions for customers.

For customers who do not have product 3D models, we will provide free 3D modeling.

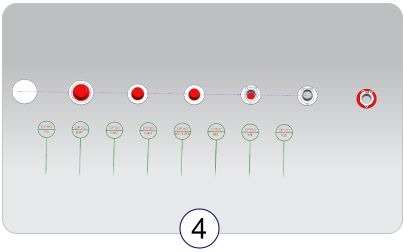

To minimize material waste and save manufacturing costs to the greatest extent possible.

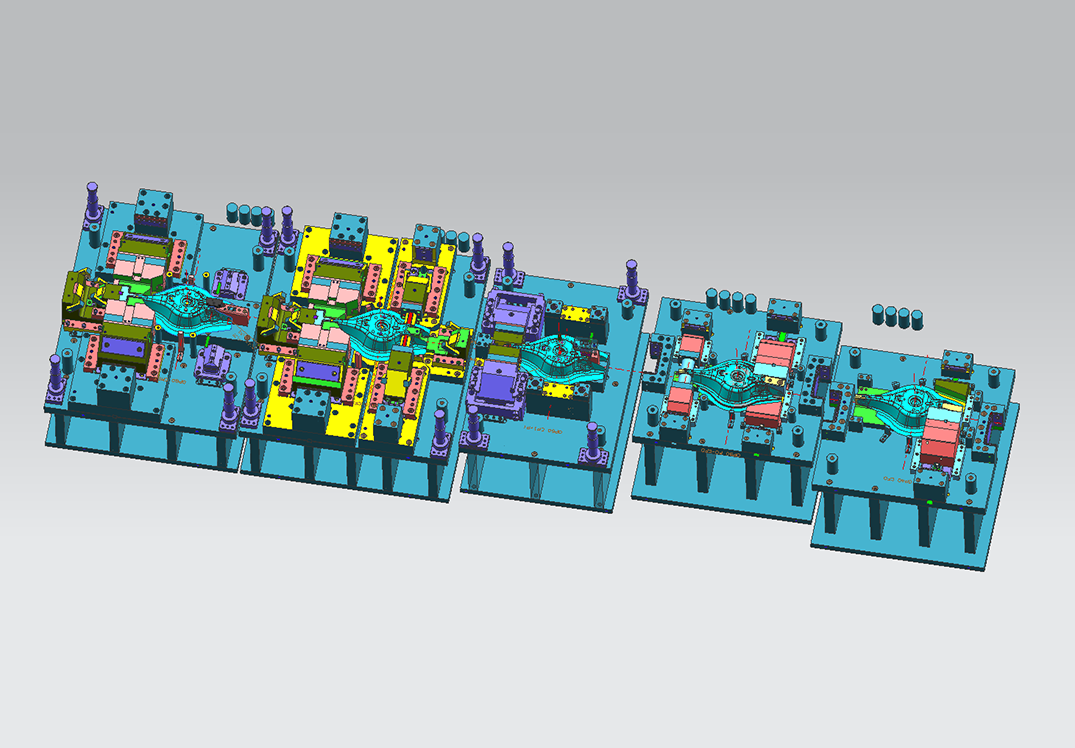

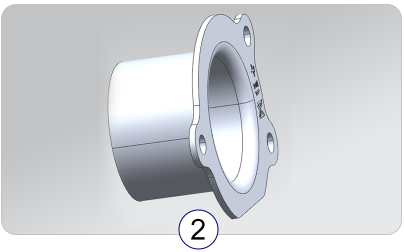

Automotive stamping dies are critical tools in the manufacturing of automobiles, primarily composed of upper and lower dies. They directly influence the shape and quality of components, determining the precision of the final product. The upper die comprises the upper die seat, upper die plate, and upper die cavity, while the lower die consists of the lower die seat, lower die plate, and lower die cavity. Guide pillars, guide bushes, locating pins, and bolts ensure the stable alignment of the dies. The punch applies force to stamp the raw material into the desired shape, with the die shoe and die holder supporting the lower and upper dies, respectively.

Get A Quotation

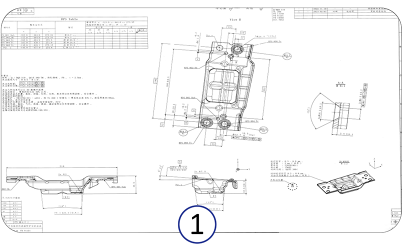

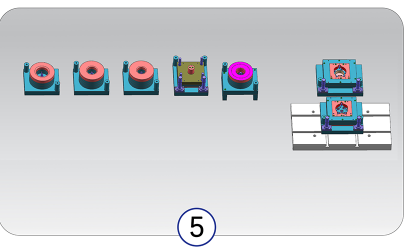

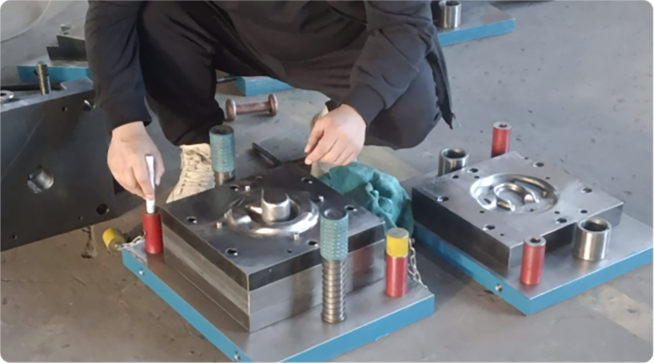

After the customer confirms the Blu-ray report, Shaoyay will provide the following two kinds of mold quality inspection services, namely static acceptance and dynamic acceptance, to ensure that the appearance, protection and production process of the mold remain smooth.

Mold dynamic detection is carried out when the mold is moving. This inspection method pays more attention to the performance and stability of the mold in actual production. Dynamic mold inspection may include monitoring and analyzing aspects such as vibration, noise and temperature rise during mold movement to ensure that the mold performs well over a longer period of time without causing problems in actual production.

Static mold inspection is carried out when the mold is at rest. This includes checking the static characteristics of the mold, such as appearance, size, and shape. In static mold inspection, measuring tools and inspection instruments are usually used to check whether the geometric parameters of the mold meet the design requirements and identify surface defects or cracks. This helps to ensure the quality and accuracy of the mold.

1.To help customers analysis structure of products's design, and provide effective opinions.

2.To confirm material will meet the structure of the product's design, reducing waste.

3.Whether the product can adopt a design that reduces materials to reduce product costs.

4.To analysis molds structure, confirm the best molds structure and achieve maximizing of efficiency in production.

5.Whether the product needs to add surface treatment process points.

6.Whether there are any difficulties with the product structure and whether if needs to be modified or simplified.

| Processing Capabilities | Processing Capabilities | ||

| Maximum part Size | 300mm*200mm*200mm | Perpendicularity | 0.05mm |

| Minimum Part Size | 8mm*6mm*4mm | Oxidize | Film thickness 8-15um |

| Tolerances | 0.02mm | Heat treatment | Hardness 28°-65° |

| Concentricity | 0.05mm | Electrophoresis | Film thickness 15-35um, salt spray test 720h without red rust |

| Roughness | Ra0.8 | Galvanized nickel | Film thickness 8-15um, salt spray test 1500h without red rust |

| Remark |

| zhangasn | Manufacturing Processes and Materials | Manufacturing Processes and Materials | |

|---|---|---|---|

|

CNC Machining Materials

|

Metals

Aluminum Brass Copper Stainless Steel Steel Alloy Steel Mild Low Carbon Titanium |

Pipe Processing

|

steel tube

Carbon tube Alloy pipe stainless steel pipe Aluminum alloy plate 6061 Aluminum 6082 Aluminum 7075 Aluminum |

|

Cold Extrusion

|

steel

Carbon steel Alloy steel stainless steel Aluminum 6061 Aluminum 6082 Aluminum 7075 Aluminum |

Our engineers ensures maximum productivity and cost efficiency for client projects.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.