Wie Blechformteile im Fahrzeugkarosserie- und Fahrzeugrahmenbau eingesetzt werden

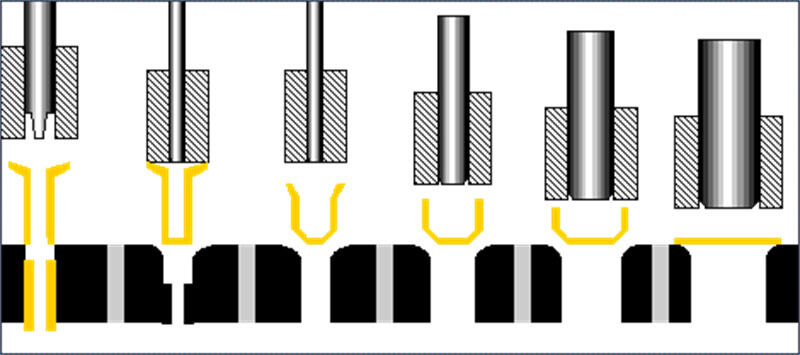

In der Automobilherstellungsindustrie, metallprägung für Automobil teile sind essenziell für die Produktion von Schlüsselkomponenten für Fahrzeuge. Der Prozess der stanzerei für Automobile teile besteht darin, Druck auf eine Metallplatte auszuüben, um sie in die gewünschte Form zu pressen. Dieser Prozess ist entscheidend für die Fertigung von Komponenten, die zur strukturellen Integrität, Sicherheit und Gesamtleistung des Fahrzeugs beitragen. In diesem Blog werden wir untersuchen, wie automobil-Pressmaschinen technologie in der Produktion von fahrzeugkarosserie und fahrgestell komponenten.

Die Rolle von Auto-Presseteilen in der Produktion von Fahrzeugkarosserie und Fahrgestell

Wenn es um die Fahrzeugproduktion geht, ist die karosserie und fahrgestell sind die grundlegenden Elemente jedes Fahrzeugs. Diese Komponenten müssen leichtgewichtig, aber dennoch robust sein, um die Leistung, Sicherheit und Kraftstoffeffizienz des Fahrzeugs zu gewährleisten.

Stanzerei für Automobile teile werden hergestellt, um den komplexen Anforderungen von fahrzeugkarosserie und fahrgestell produktion gerecht zu werden. Komponenten wie Türbleche, Kotflügel und Fahrgestellrahmen werden oft mit metallumformungsdienstleistungen . Der metallstanzen-teile in diesem Prozess hergestellten Teile sind präzise geformt, um den Spezifikationen des Fahrzeugs zu entsprechen.

metallumformungsdienstleistungen

Die automobil-Pressmaschinen wird verwendet, um wesentliche Karosserieelemente wie viertelbleche , dachbleche und bleche , die sowohl ästhetische als auch funktionelle Zwecke erfüllen. Diese Teile müssen strenge Standards in Bezug auf Stärke, Haltbarkeit und dimensionsgenaue Präzision erfüllen.

Warum Präzision in der Autoumformung für Karosserieelemente wichtig ist

Genauigkeit ist der Schlüssel bei der Produktion von Karosserieelementen. Die automobil-Pressmaschinen ermöglicht Herstellern die Erstellung von metallstanzen-teile mit exakten Spezifikationen, wodurch sichergestellt wird, dass Karosserieelemente perfekt zusammenpassen. Diese Präzision ist sowohl für die Strukturintegrität als auch für das ästhetische Erscheinungsbild des Fahrzeugs entscheidend. Darüber hinaus sorgt die Genauigkeit in der metallprägung für Automobil für eine Hochgeschwindigkeitsproduktion von Teilen ohne Kompromisse bei der Qualität.

Fertigung von Stanzteilen für die Automobilindustrie

Vorteile der Metallstanzen in der Fahrzeugkarosserieherstellung

Einer der Hauptgründe, warum metallprägung für Automobil teile in der Fahrzeugkarosserieherstellung eingesetzt werden, ist die Fähigkeit, hochpräzise Komponenten in hoher Geschwindigkeit herzustellen. Stanzteilshersteller verwenden fortgeschrittene automobil-Pressmaschinen maschinen zur Herstellung von Teilen mit konsistenter Qualität, was für die Massenfertigung von Fahrzeugen essenziell ist.

Darüber hinaus, metallstanzen-teile bieten die notwendige Stärke, während sie das Gesamtgewicht des Fahrzeugs niedrig halten. Diese Balance ist entscheidend für den Verbesserung des Kraftstoffverbrauchs und das Erreichen von Umweltstandards. Fortgeschritten automobil-Pressmaschinen maschinen ermöglichen es Herstellern, komplexe Formen wie gekrümmte oder konturierte Oberflächen mit hoher Präzision und minimalem Materialverlust herzustellen.

Schnelle Produktion von Metallduromatikformen

Kostengünstige Massenproduktion durch Metallumformung

Metallumformungsdienstleistungen bieten eine effiziente Methode zur schnellen und kostengünstigen Fertigung großer Mengen an Teilen. Durch die Nutzung von automobil-Pressmaschinen technologie können Hersteller hohe Produktionsmengen erfüllen, während sie eine hohe Qualität aufrechterhalten, was für die wettbewerbsfähige Automobilindustrie essenziell ist.

Schlüsselkomponenten, die durch Metallumformung im Fahrzeugrahmen hergestellt werden

In der Produktion von fahrzeugrahmen , stanzerei für Automobile teile werden verwendet, um tragende Komponenten wie Querträger, Untergestelle und Federbefestigungen herzustellen. Diese Teile sind entscheidend für die gesamte Stabilität und Festigkeit des Fahrzeugs.

Metallumformungsdienstleistungen hilfe stanzteilshersteller produzieren große Mengen an präzisen Teilen, die für Fahrgestellssysteme benötigt werden. Bauteile wie rahmenprofile und bodenbleche werden normalerweise hergestellt unter Verwendung von metallstanzen-teile wegen ihrer hohen Festigkeitsanforderungen und der Notwendigkeit kostengünstige Massenproduktion durchzuführen.

Die Bedeutung von Präzision bei Fahrgestellkomponenten

Beim Herstellen fahrgestell bei der Herstellung von Komponenten ist es essenziell, dass die Teile sowohl präzise als auch haltbar sind. Die automobil-Pressmaschinen technologie ermöglicht es metallprägung für Automobil den strengen Spezifikationen für tragende Bauteile zu genügen. Dies gewährleistet die Gesamtstabilität und Sicherheit des Fahrzeugs, wodurch Präzision ein wesentlicher Aspekt des Fahrgestellherstellungsprozesses wird.

Warum Metalldruckdienstleistungen für die Automobilproduktion wählen?

Für stanzteilshersteller , bietet metallumformungsdienstleistungen für die Automobilproduktion bietet zahlreiche Vorteile. Zunächst einmal ist metallstanzen eine äußerst effiziente Methode zur schnellen Fertigung großer Mengen an Teilen. Dies hilft Automobilherstellern anspruchsvolle Produktionspläne einzuhalten, während gleichzeitig hohe Qualitätsstandards gewahrt werden.

Darüber hinaus sorgt die fortschrittliche automobil-Pressmaschinen technologie dafür, dass hochwertige Teile mit minimalen Fehlerraten hergestellt werden. Dies ist im Automobilbereich entscheidend, wo Komponenten strengen Sicherheits- und Regulierungsanforderungen gerecht werden müssen. Metallumformungsdienstleistungen ermöglichen es zudem, Produktionskosten zu senken, während die Qualität erhalten bleibt, was den Herstellern ermöglicht, wettbewerbsfähig zu bleiben.

Kosten- und Zeit-effizienz in der Automobilproduktion

Durch die Nutzung metallprägung für Automobil technologie, stanzteilshersteller kann signifikante Zeit- und Kosteneinsparungen in der Produktion von Automobilteilen erzielt werden. Unabhängig davon, ob es sich um fahrzeugkarosserie oder fahrgestell komponenten handelt, metallstanzen-teile bieten eine zuverlässige und effiziente Lösung, die den hohen Anforderungen der Automobilindustrie gerecht wird.

Fazit: Die Zukunft der Metallumformung im Automobilbau

Da die Automobilindustrie weiterentwickelt, wird die Nachfrage nach leistungsstarken metallprägung für Automobil teilen weiterhin wachsen. Die Entwicklung von automobil-Pressmaschinen technologie ermöglicht es stanzteilshersteller komplexere, hochwertige Komponenten zu einem niedrigeren Preis herzustellen. Unabhängig davon, ob für fahrzeugkarosserie oder fahrgestell , metallstanzen-teile wird diese weiterhin kritisch im Automobilbau sein.

Da die Branche increasingly towards nachhaltigere und leichtere Fahrzeuge strebt, metallumformungsdienstleistungen wird eine immer wichtigere Rolle bei der Erfüllung dieser Anforderungen spielen. Durch innovative Lösungen und hochwertige Produktion, metallstanzen wird weiterhin die Zukunft der Automobilherstellung gestalten.