Otroško štampovanje je ključen proces v svetu izdelave avtomobilov. Ta proces je pomemben za različne komponente avtomobila. Shaoyi je podjetje za avtomobilsko štampovanje. Oni del iz kovinske pločevine za avtomobilsko industrijo imajo posebno opremo in izkušnje, da lahko svoje deli naredijo tako, da delujejo in se pravilno prilegajo. Zato si oglejmo bolj podrobno avtomobilsko štampovanje in kako deluje. Otokarsko štampovanje je proizvodni postopek, ki ustvarja avtomobilske deli s ploščastimi kovinski listi. Takšne dele so od vrata do kapot in kril, med drugim. Vse začne z ravnimi kovinskimi listi, ki jih vpihajo v ogromno strojno napravo, imenovano štampna lisica. Ta stroj je zelo močan in uporablja sofisticirano opremo, znano kot šablon in udarci. Šablon in udarci izrežeta in oblikujeta kovino v pravilen avtomobilski komponent. Vključuje uporabo kovinskih listov in 'pritisnitev' njih v komponente, ki bodo združene za izgradnjo avtomobila.

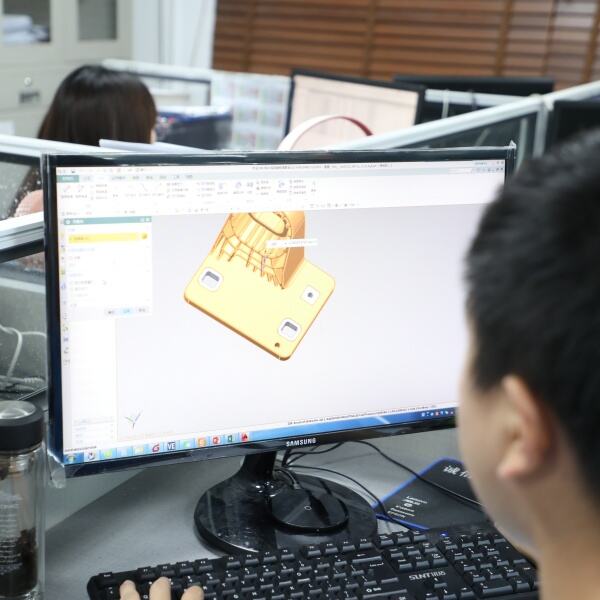

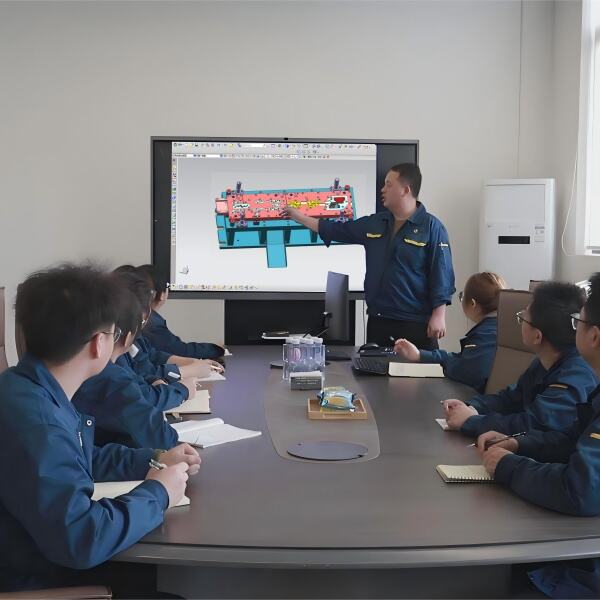

Očesovanje za avtomobilsko industrijo je nedeljivi del izdelave avtomobilov, saj se praktično vse dele avtomobila lahko izdelajo v zelo kratkem času. Na primer, podjetje Shaoyi ponuja očesovalne stroje, ki lahko proizvedejo tisoče avtomobilske komponente v minimalnem času. Ta hitrost je zlasti pomembna, ker je avtomobilska industrija zelo konkurenčna. To odlaganje avtomobilskega dela pomeni, da lahko proizvajalci avtomobilov hitreje dostavijo vozila v roke strankam, če jih izgradijo hitreje. To pomeni, da omogoča avtomobilska odtisna tehnologija, da se prilagaja naraščajoči potrpevi po avtomobilih, saj bo bilo na voljo dovolj komponentov za sestavljanje vozil brez zakasnitev. Proces avtomobilskega odtisovanja je danes drugačen, hvala tehnologiji. Shaoyi uporablja specializirano računalniško programsko opremo za načrtovanje komponentov avtomobila. Ta programska oprema ustvari orodja, s katerimi delujejo odtisne strojevi. Shaoyi lahko svojim strankam zagotovi točne in natančne dele z vsemi teh tehnologijami. To pomeni tudi, da bo vsak komponent pravilno poravnava z ostalimi komponenti avtomobila. Odtisni stroji sami so opremljeni s sodobno tehnologijo, ki zagotavlja, da je vsak izdelek pravilne velikosti in standardiziran primerno. Ta tehnologija je ključna, ker pomaga izogniti se napakam in zagotovi, da vsi komponenti ustreza standardom.

Pred dve leti, med procesom ureditve vseh mojih knjig, sem odkril, kako hitreje pride do prehoda iz osnove v ureditev, ko pišem koherentno. Ko pišemo neizdelano osnovo, se pojavlja veliko napak, odlagališke avtomobilske deli kar deluje skoraj kot blokada in lahko traja celo dlje, kot če bi pravilno naredili osnovne stvari že na začetku — vsaj mi to kaže izkušnja po ponovljenih srečanjih s tem fenomenom!

Avtomobilska štampa je postopek, ki zahteva visoko stopnjo hitrosti in natančnosti. Imaš štampanjske stroje, ki so zelo hitri in razvijajo dele v kratkem času. Končno, ti stroji pomembno prispevajo k zmanjšanju odpadkov, saj štampa ne vključuje neposrednega odbiva velike količine materiala. Ta učinkovitost je tako okolju prijazna kot tudi cenovno učinkovita za podjetje. Poleg tega morajo biti tudi štampni stroji natančni, sicer bodo deli nesprejemljive kakovosti. Te deli iz kovinskih pločevin za avtomobilsko industrijo nato preverijo s posebnimi senzorji in nadzornimi sistemami, da so pravilne velikosti in oblike. Ta posvečenost pomaga zagotoviti, da je vsaka komponenta izdelana po specifikacijah in dobi primerno potrdilo kakovosti.

Metalna odlagovanja v avtomobilski industriji sta postopek, v katerem pride kakovostni nadzor na prvo mesto. Predvsem trdi Shaoyi, da morajo zaposleni poudarjati kakovost pri odlagovanju. Ti štampanje avtomobilskih listov kovine imajo večplastne postopke potrditve, ki potrjujejo, da so deli zadostno primerjni za uporabo v avtomobilih. Te preveritve lahko vključujejo tudi vizualne pregledave, kjer delavci pregledujejo dele za odkrivanje vidnih težav. Merijo tudi dele, da se prepričajo, da so pravilne velikosti. Poleg tega izvajajo tudi testiranje materialov, da se uporablja močan in trajen kovinjen. S temi preveritvami kakovosti si Shaoyi lahko prepusti kakovost in zanesljivost del, ki jih proizvaja za uporabo v avtomobilih.

Zelo smo ponosni, da držimo certifikat IATF 16949, ki je dokaz naše izjemne učinkovitosti v upravljanju kakovosti, ki jo želimo doseči v avtomobilski industriji. Naša oddelek za kakovost ima popolno Vladanje petimi ključnimi orodji kakovosti, vključno s Statističnim Nadzorom Postopkov (SPC), Analizo Merilnih Sistemov (MSA), Analizo Posledic in Spodletitev (FMEA), Napredno Planiranje Kakovosti Proizvodov ter Postopek Odobritve Proizvodnih Delov. Poleg tega je osebje za kakovost zaključilo obsežno šolanje Six Sigma, kar zagotavlja, da pridržavamo najstrožjim standardom kakovosti proizvodov. Ta celovit pristop k nadzoru kakovosti zagotavlja, da vsak proizvod, ki ga ponujamo, ne le izpolnjuje, ampak pogosto presegne pričakovanja industrije, hkrati pa nudimo našim strankam zaupanje in zadovoljstvo z našimi storitvami.

Več kot 90 % naših izdelkov je namenjeno avtomobilski industriji. Ponujamo kakovostne deli, ki so primerni za širok obseg vozil, vključno s potniškimi avtomobili, golfskimi vožili, poslovnimi vozili ter motorji, kamiony in traktorji. Naša raznolika ponudba izdelkov je dokaz naše sposobnosti, da izpolnimo vse zahteve trga za avtomobile. Privilegirani smo tudi kot glavni ponudnik suspendijskih sistemov Volkswagenu v Kitajski, kar pokaže našo sposobnost ponuditi zanesljive in revolucionarne rešitve najprestigiješim avtomobilskim znamkam. Naše dolgoročno industrijsko znanje omogoča, da naši izdelki ne le izpolnjujejo, ampak presegajo očakovanja strank glede zmogljivosti in kakovosti.

Zelo smo ponosni na naš posvečeni raziskovalno razvijalni oddel, v katerem ima vsak inženir več kot 10 let izkušenj v avtomobilski industriji. To znanje nam omogoča, da razumemo edinstvene lastnosti in procese različnih materialov, kar nam omogoča, da ponujamo prilagojene rešitve našim strankam. Ponujamo profesionalno analizo CAE ter razvoj produkta in tehnično pomoč ter tudi popoln poročil DFM, da se zagotovi, da je vsak aspekt načrta razvit za izpolnitev zahtev proizvodnje. Zavezani smo inovacijam in ponujamo kakovostne metalne produkte, ki izpolnjujejo natančne zahteve naših strank.

Naše podjetje, ki pokriva več kot 10.000 kvadratnih metrov in se osredotoča na proizvodnjo kovinskih delov za več kot 30 avtomobilske znamke, ima več kot 15 let izkušenj v tem poslovnem področju. Uporabljamo najnaprednejše obdelovalne tehnike, kot so štampovanje, CNC obravnava strojev, proizvodnja form, ter litje pod tlakom, da se zagotovi, da je vsak izdelek visoke kakovosti. Naše stroge postopke nadzora kakovosti zagotavljajo, da so razsežnosti in obliki enaki, ter tudi v izvedbi. Vse to gradimo zaupanje in zadovoljstvo med našimi strankami.