With 15 years of experience in customized processing of automotive zip ties, we have rich professional knowledge throughout the entire process chain of automotive zip ties. Operating within our technology center, we are committed to sharing our knowledge with you, assisting in process improvement, and establishing automotive ties as the preferred method for automotive component parts.

IATF TS16949:2016/Critical to Quality

Parts finished each month

R&D Engineer

Steel & Aluminum

We use a variety of quality control methods to ensure that the products we deliver to our customers are of the right size and performance for their needs.

Our unwavering commitment to quality is bolstered by our IATF 16949 certification, ensuring a stringent quality control system throughout every phase of production. This certification is a testament to our meticulous approach, from the initial design to the final product delivery. -IATF16949 Certification

Leveraging top-tier production and inspection equipment, our state-of-the-art, fully automated machinery guarantees product quality with every manufacturing process, ensuring consistency and excellence in every output.

Our team of technical experts, each with over a decade of experience in metal fabrication, forms the backbone of our operations. These elite engineers bring a wealth of knowledge and expertise to every project, ensuring that our products not only meet but exceed industry standards for quality and innovation.

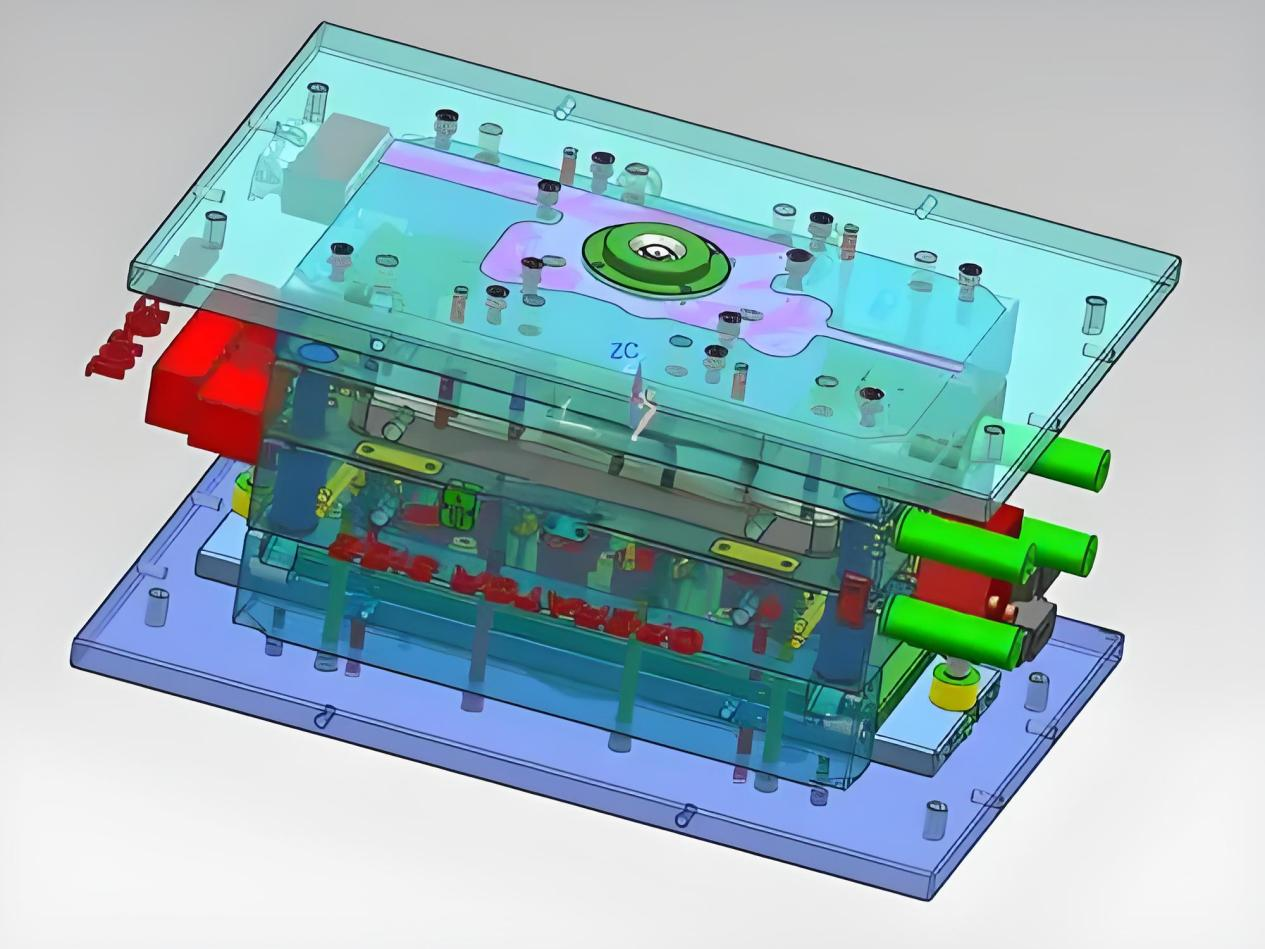

We have a variety of processing technologies such as precision stamping, laser cutting, machining, welding, surface treatment, automated assembly, etc.

We have a professional R&D team with over 10 years of experience in the automotive industry. Our expertise enables us to assist customers in the initial development of automotive injection molded products and provide tailored solutions to meet their needs and challenges.

Our company has a complete quality control system, which is controlled through QC reports throughout the entire production process. We have advanced equipment such as size testing, chemical composition analysis, non-destructive testing, and so on.

Using fine materials,binding force of 8oN,and other products on the market is only 40-50N,with high strength bundling is not easy to slack off.

| Processing Capabilities | Remark | ||

|---|---|---|---|

| Origin | China | Colour | The standard color is (black/natural) and other colors can be customized if needed

authentication UR |

| Apply | Fixed bundling | Packing | The quantity of inner packaging small packages is PCS100/500/1000, and the size of the outer packaging cardboard box is 430mm * 330mm * 300mm. According to the length of the product, it is 3000PCS/4000PCS/6000PCS/8000PCS/10000PCS respectively |

| Tensile strength | 180N-260N | Bundle diameter | 3mm-80mm |

| Material | PA66 | Working temperature | -40-150 |

| Tensile strength | 180N-260N | Features | Convenient, fast bundling, stable fixation |

| Certificate | ROHS2.0 | Usage | Fixed and tightened |

| Application scope | Fixation of wiring harnesses for automobiles, high-speed trains, and ships, as well as various equipment, household appliances, new energy, and other scenarios | Delivery time | 15-30 (working days) |

| Manufacturing Processes and Materials | Manufacturing Processes and Materials | ||

|---|---|---|---|

|

Mold Material |

SK61 Type, H13 Type |

Product material

|

ADC10、ADC12、A360、4380、4413、A356、LM20、LM24 zinc alloy3#、5#、8# |

Focus on chassis welded assemblies, shock-absorbing welded assemblies, chassis stamping, and machining parts.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.