Hej derude! Fortsæt med at læse for at få en lille indsigt i, hvordan vi laver bildele af plast. Denne procedure kaldes plastmasseindstrykning. Det er dog ret fedt, som Shaoyi automobilformen bare smelter plasten, varmer den op til en temperatur, hvor den kan formes og derefter bare former den til disse dele, der laver biler. Hvordan er det ikke fantastisk at tænke på? Bildele består af hundreder af elementer, og i dag produceres en af dem ved hjælp af plastmasseindstrykning.

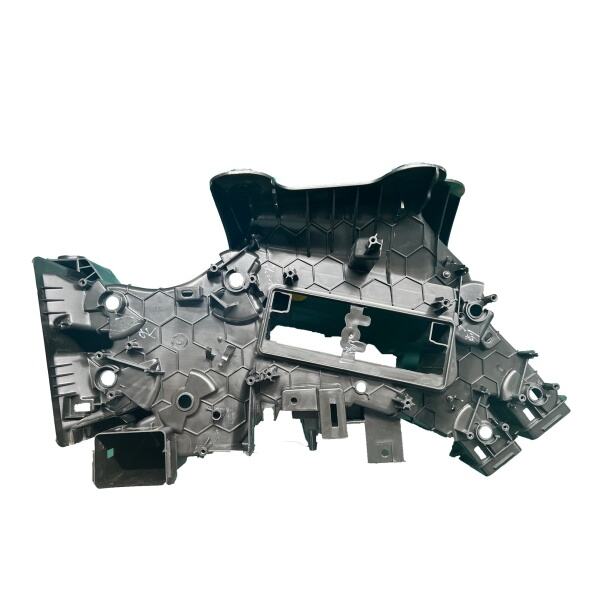

Således vil vi gå over i detaljerne om plastikken injektionsformning - hvad handler det egentlig om? Det er måden, hvorpå man producerer formen ud fra den smeltede plast. Formen er præcist en type hylde, der kan tage formen på plastmaterialet, der skal bruges. Dette opnår vi ved at lade den varme, smeltede plast køle ned, efter at vi har hældt den ind i formen. Plasten bliver fast efter køling og kan genbruges som et bestemt bildele. På denne måde er det lige så godt som at lave bildele, og det kan gøres hurtigere og enklere på få timer!

Men for eksempel, når vi producerer bildele, er det meget vigtigt, at bilens elementer monteres præcist. Hvis ét af DFD-elementerne er stort, vil det andet enten være for stort til at passe ind i det eller for lille til at kunne tage det store element. Det betyder, at vi SKAL være super nøjagtige! Hver form, der fremstilles, skal opfylde disse krav hver eneste gang. Iblandt er det ikke simpelt, men på Shaoyi har vi ressourcerne og mandkraften til at gennemføre det hver eneste gang. Vi tror på at få alt til at passe sammen smidigt, som hvert stykke i et puslespil!

Plastmasseindstrykning, lige som alle andre aspekter i verden, er en voksende teknologi og produktionss proces. Ligesom med legetøj/spil, der produceres og lanceres på markedet regelmæssigt, udvikles der nye produkter til formgivning hver dag. Der findes også godt dokumenteret bevis for, at vores maskiner bliver smartere dag for dag. Som resultat her hos Shaoyi fortsætter vi med at eksperimentere og forfinde Shaoyi automotive die . Vi bruger den bedste proces og produktmaterialer, hvilket vil give os mulighed for at opføre kvalitets- og sikre dele.

Plast kan blive endnu mere kompliceret, når det gælder at designe bildele. Det kan være fyldt med hindringer, som vi måtte springe over i processen af at udføre arbejdet. Vi skal også kontrollere, at plasten er præcist den rigtige temperatur før den bliver hældt ind i formen. Dette vil imidlertid ikke fungere, hvis vandet er for varmt eller for kuldt. Vi skal også overvåge luftboblerne i formen, da de forårsager flere problemer senere. Men rolig! For de udfordringer, vi støder på, har Shaoyi et professionelt seniorhold, der forstår, hvordan man tager fat i udfordringen for organisationen. Det er blevet aftalt, at vi tager fat i problemene sammen og gør alt muligt for at sikre, at alt går så smoothly som muligt.

Nåja, der er ingen tvivl om, at plastmasseindstrykning er en af de bedste måder at lave fantastiske bildele på, men spørgsmålet i vores tilfælde er hvordan. Det bedste ved det er, at det er dér, hvor alt kaffe-magiet sker som et resultat af at knuse gennem alt det kedelige arbejde. Og når vi bygger dele til biler, ja, de falder bare på plads sammen, som de skal. Shaoyi bildeleformning gør bilen til at fungere som forventet og sikrer, at alle personer inde i er beskyttet, når den bruges.

Vores virksomhed specialiserer sig i automobilproduktion, med over 90 procent af vores produkter fokuseret på automobilindustrien. Vi leverer højkvalitetskomponenter til en bred vifte af køretøjer, herunder personbiler, erhvervsbiler, golfvogne samt motorcykler, lastbiler og traktorer. Denne omfattende produktportefølje illustrerer vores fleksibilitet og engagement i at opfylde de diverse behov i automobilmarkedet. Desuden er vi stolte af at være den førende leverandør af suspensionsystemer til Volkswagen i Kina, hvilket viser vores evne til at tilbyde pålidelige og revolutionære løsninger til store automarkevarer. Vores omfattende industrielle erfaring gør vores produkter ikke kun til at opfylde, men også overstige kundens forventninger til ydelse og kvalitet.

Vi er utrolig stolte af at holde IATF-certifikationen 16949, hvilket er et vidnesbyrd om vores fremragende kvalitetsledelse, som vi streber mod at opnå inden for bilindustrien. Vores kvalitetsafdeling har færdigheder inden for fem afgørende kvalitetværktøjer, herunder Statistisk Processtyring (SPC), Analyse af Målesystemer (MSA), Analyse af Fejlmodi og Effekter (FMEA), Avanceret Produktkvalitetsplanlægning og Godkendelsesprocessen for Produktionselementer. Desuden har vores kvalitetspersonale fuldført omfattende Six Sigma-uddannelse, hvilket sikrer, at vi overholder de strengeste standarder for produktkvalitet. Denne omfattende metode til kvalitetskontrol sikrer, at hvert produkt, vi leverer, ikke kun opfylder, men ofte overstiger industiens forventninger, og giver vores kunder tillid og tilfredshed med vores tjenester.

Med mere end 15 års erfaring inden for automobilsektoren dækker vores virksomhed et område på over 10.000 kvadratmeter og specialiserer sig i produktion af metaldele til mere end 30 automobilmærker. Vi bruger avancerede bearbejdningsmetoder, herunder presning, CNC-maskinbearbejdning, formgøremål og aluminiumsprøjteformning for at sikre, at hvert produkt opfylder de højeste kvalitetsstandarder. Vores strenge kvalitetskontrolprocedurer sikrer, at vores produkter er konstante med hensyn til dimensioner, form og ydelse. Dette skaber tillid og troværdighed hos vores kunder.

Vi er stolte af vores engagerede forsknings- og udviklingsafdeling, hvor hver ingeniør har mere end 10 år erfaring inden for automobilbranchen. Denne ekspertise gør os i stand til at forstå de unikke egenskaber og processer ved forskellige materialer, hvilket giver os mulighed for at tilpasse løsninger til vores kunder. Vi tilbyder professionel CAE-analyse, produktudvikling og teknisk support sammen med detaljerede DFM-rapporter for at sikre, at hvert aspekt af designet er optimeret til produktion. Vi er dedikeret til at fremme teknologien og tilbyde høj kvalitet metaldele, der opfylder de specifikke behov hos vores kunder.