Bildele spiller en afgørende rolle for at sikre, at biler kører smidigt og sikkert på vejen. En bil uden de nødvendige dele kan ikke fungere korrekt, hvilket kan føre til potentiel farlige konsekvenser. Dog er det under intet område en simpel opgave at fremstille disse komponenter. Det stansede autodele kræver veltrænede specialister, det rigtige udstyr til at lave alt og en dyb forståelse af, hvordan bildele fungerer. Her kommer Shaoyi ind i billedet. Vi er ekspert på produktion af bildele, og vi har friske ideer, der bør hjælpe os med at producere dem hurtigt og godt. En af disse typer er værktøjet, der producerer gifs som gode løsninger for rå billeder, undtagen de, der hedder specielle værktøjer til perfekte bildele.

De bildele, der skal fremstilles til præcise dimensioner og fungere korrekt, skal produceres med disse værktøjer. Shaoyi har staten af kunsten maskineri og nyeste teknologi, hvilket gør os i stand til at producere høj kvalitet dele. Vores udstyr er sat op for at hjælpe os med at skabe komponenter af forskellige former og proportioner. Det betyder, at vi kan lave dele, der er nøjagtigt tilpasset det, vores kunder kræver. Alle vores dele bliver også grundigt kontrolleret på kvalitet. Dette automotive stansdel betyder, at vi sørger for, at alle dele, vi laver, bliver til en fremragende enhed, og vil tjene dig godt i årevis. Hos Shaoyi moderniserer vi konstant vores processer med fokus på hastighed og effektivitet. For eksempel bruger vi en proces kaldet Deep Draw Stamping. Princippet fungerer ved at nemt og hurtigt skabe komplekse geometriske dele. Vi bruger robotter til at automatisere arbejdet, så vores processer kan køre hurtigere, og vi kan producere flere dele i mindre tid. Med hjælp fra disse innovationer og teknologier kan vi minimere spild og forbedre vores processer. Dette gør det muligt for os at holde alt organiseret, levere gode dele til rimelige priser for vores kunder.

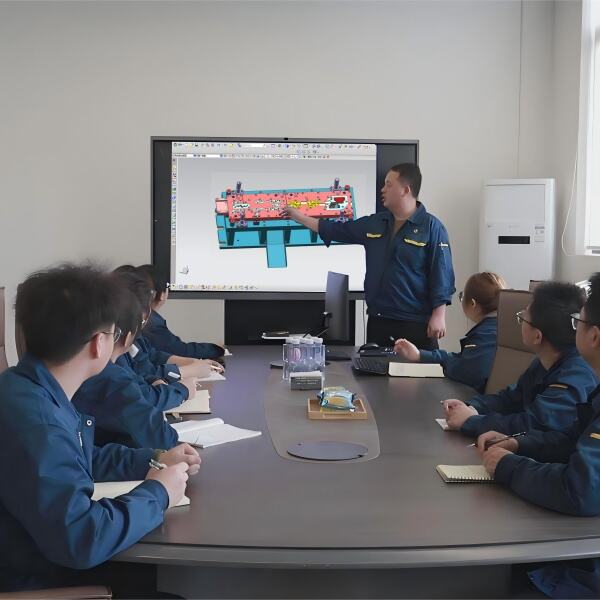

Effektive mennesker, store resultater. Vi ved, at gode bildele laves med samarbejde hos Shaoyi. Vi kommunikerer direkte med vores kunder for at forstå deres krav og forventninger til os. Dette leverandører af metalstempling til bilindustrien information er afgørende for os, fordi det giver klarhed over deres indsigt og fremtidige krav. At være på linie gør det lettere for os at kalibrere vores produktionss proces for at tilpasse det til deres behov, og sådan løber tingene smertefrit. Vi betragter os selv som partnere med vores kunder og skaber sammen deres komponenter. Det er, hvad der sikrer, at vi kan få de fantastiske, virkelig fantastiske ting gjort.

Dog anerkendes Shaoyi for at bevare kvaliteten på mange komponenter. Vi ved, hvordan man producerer masse gode komponenter og inspicerer hver enkelt komponent omhyggeligt. Vi følger et sæt strikte standarder for at sikre, at alle vores komponenter er af højeste kvalitet. Vores nyeste maskiner sammen med processer gør det muligt for os at handle hurtigere og effektivt, hvilket giver os mulighed for at producere meget mere, samtidig med at vi opretholder de samme kvalitetsniveauer. Dette automotive plade metal stempling er blot for at minde vores kunder om, at de altid vil modtage det bedste.

Shaoyi har omfattende viden og ekspertise inden for produktion af bildele. Vi har færdige arbejdstagere, der undersøger alt på alle stadier af fremstillingen af vores produkter. Vi ved, hvordan vi leverer højpræcise løsninger og arbejder hårdt fortsat for at sikre, at vores kunder er tilfredse med formning af bilkomponenter kvaliteten af de dele, de har modtaget. Vi er meget motiverede til at tilbyde fremragende presningsløsninger, fra regelmæssig uddannelse og inddrivning af arbejdsstyrken til opdateret teknologi.

Vi er stolte af at kunne holde IATF-certifikationen 16949, som et bevis på vores engagement i kvalitetsledelse fremragenhed inden for automobilindustrien. Vores kvalitetsafdeling er dygtig i at bruge de fem nøgletaster for kvalitet: Statistisk Processtyring (SPC), Målesystemanalyse (MSA), Analyse af Fejltilstande og Effekter (FMEA), Avanceret Produktkvalitetsplanlægning (APQP) og Godkendelsesprocedure for Produktionselementer (PPAP). Vores kvalitetspersonale er gået igennem omfattende Six Sigma-uddannelse, hvilket sikrer, at vi overholder de strengeste standarder for produktkvalitet. Vores omfattende tilgang til kvalitetsledelse sikrer, at vores produkter ikke kun matcher, men ofte overstiger branchestandarder, og giver også vores kunder tillid og fuld tilfredshed med vores tjenester.

Vores virksomhed er en leder inden for produktion af automobilkomponenter, med over 90 procent af vores produkter designet til den automobilrelaterede sektor. Vi tilbyder højkvalitetsdeler til en bred vifte af køretøjer, herunder personbiler, golfvogne, erhvervsfartøjer, motorcykler, lastbiler og traktorer. Vores omfattende produktudvalg viser vores engagement i at opfylde de diverse behov på markedet for automobiler. Vi er også stolte af at være den største leverandør af suspensionsystemer til Volkswagen i Kina, hvilket understreger vores evne til at tilbyde pålidelige og revolutionære løsninger til store automarkevarer. Vores udstrakte industrielle erfaring gør det muligt for vores produkter ikke kun at opfylde, men endda overstige kundernes forventninger vedrørende ydeevne og kvalitet.

Vi er meget stolte af vores engagerede forsknings- og udviklingsafdeling, hvor hver ingeniør har mere end 10 år med erfaring inden for automobilbranchen. Denne ekspertise gør os i stand til at forstå den unikke natur og karakter af de forskellige materialer, hvilket giver os mulighed for at tilbyde tilpassede løsninger til vores kunder. Vi tilbyder ekspert CAE-analyser i produktudvikling, teknisk support samt omfattende DFM-rapport for at sikre, at hvert aspekt af designet er optimeret til produktion. Vi er dedikeret til at fremme teknologien og tilbyde topklasse metalprodukter, der er designet til at opfylde kravene fra vores kunder.

Med mere end 15 års erfaring inden for automobilsektoren dækker vores virksomhed et område på over 10.000 kvadratmeter og specialiserer sig i produktion af metaldele til mere end 30 automobilmærker. Vi bruger avancerede bearbejdningsmetoder, herunder presning, CNC-maskinbearbejdning, formgøremål og aluminiumsprøjteformning for at sikre, at hvert produkt opfylder de højeste kvalitetsstandarder. Vores strenge kvalitetskontrolprocedurer sikrer, at vores produkter er konstante med hensyn til dimensioner, form og ydelse. Dette skaber tillid og troværdighed hos vores kunder.