自動車プレス部品が車体およびシャシー生産でどのように使用されるか

自動車製造業界では、 金属スタンプ自動車 部品は車両の主要な部品を製造するための重要な要素です。このプロセスでは、金属板に圧力をかけて望む形に成形します。このプロセスは、車両の構造的な強度、安全性、全体的な性能に寄与する部品を製造するために重要です。このブログでは、どのように 自動車部品のプレス加工にあります 部品が関与しているかについて説明します。 自動車プレス機 技術が 車体 と チャシス コンポーネント。

の生産で使用されるかを見ていきます。

車体およびシャシーの生産における自動車用プレス部品の役割 自動車ボディ と チャシス は、あらゆる車両の基本要素です。これらの部品は、車両の性能、安全性、燃料効率を確保するために、軽量でありながら耐久性が求められます。

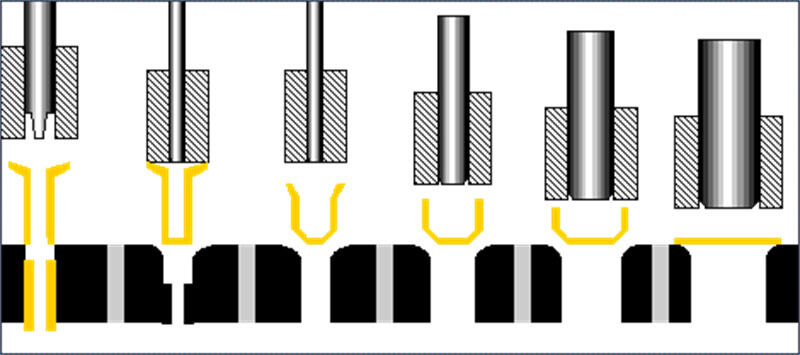

自動車部品のプレス加工にあります 部品は、複雑な要件を満たすために作られます 車体 と チャシス 生産。ドアパネル、フェンダー、シャシフレームなどの部品は通常、使用して作られます 金属圧延サービス 発表しました。 metal stamping parts このプロセスで作られる部品は、車両の仕様に正確に適合するように成形されます。

金属圧延サービス

開発の分野 自動車プレス機 は、のような重要なボディパネルを作成するために使用されます クォーターパネル , ルーフパネル および バンパー これらは、機能的だけでなく美的目的も果たします。これらの部品は厳しい強度、耐久性、寸法精度の基準を満たす必要があります。

なぜ自動車のボディパネル用の精密さが重要か

ボディパネルの生産においては精度が鍵です。その 自動車プレス機 によりメーカーは metal stamping parts 正確な仕様で製造でき、ボディパネルが完璧に組み合わされるようになります。この精度は、車両の構造的な強度と視覚的アピールの両方にとって重要です。さらに、 金属スタンプ自動車 における精度は、品質を損なうことなく部品を高速で生産することを保証します。

自動車用プレス加工部品の製造

車体生産における金属プレス加工の利点

車体生産で 金属スタンプ自動車 部品が使用される主な理由は、高精度な部品を高速で生産できる能力にあります。 プレス部品メーカー は先進的な 自動車プレス機 一貫した品質で部品を作成する機械であり、これは大量の車両生産において必要不可欠です。

さらに、 metal stamping parts 車両の全体重量を低く抑えながら必要な強度を提供します。このバランスは、燃料効率の向上と環境基準の達成に重要です。先進的な 自動車プレス機 複雑な形状、例えば曲線や輪郭のある表面などを高精度で最小限の廃棄物で製造できるようにメーカーを支援します。

金属圧縮金型の迅速な生産

金属圧延によるコスト効果の高い大量生産

金属圧延サービス 大量の部品を迅速かつコスト効果的に生産するための効率的な方法を提供します。という技術を使用することで、メーカーは高品質を維持しながら多量の需要に対応できます。これは競争の激しい自動車業界において重要です。 自動車プレス機 技術

車体シャシーにおける金属圧延によって作られる主要部品

生産において 車体シャシー , 自動車部品のプレス加工にあります 部品は、クロスメンバー、サブフレーム、サスペンションマウントなどの構造部品を作成するために使用されます。これらの部品は、車両全体の強度と剛性を確保するために重要です。

金属圧延サービス 助けて プレス部品メーカー シャシーシステムに必要な大量の高精度部品を生産します。次の部品などは、 シャシーレール と フロアパン 通常、次のようにして生産されます。 metal stamping parts 高い強度が必要であり、コスト効率の良い大量生産が必要なためです。

シャシーコンポーネントにおける精密の役割

製造する際には チャシス 部品においては、精度と耐久性が両方必要です。その 自動車プレス機 技術により 金属スタンプ自動車 構造部品に必要な厳しい仕様を満たす部品を作ることが可能です。これにより、車両全体の強度と安全性が確保され、シャーシの生産プロセスにおいて精度が重要な要素となります。

なぜ自動車生産に金属プレス加工サービスを選ぶべきか?

〜用 プレス部品メーカー 、提供 金属圧延サービス 自動車生産における金属プレス加工には多くの利点があります。第一に、 金属プレス加工 大量の部品を迅速に生産するための非常に効率的な方法です。これにより、自動車メーカーは厳しい生産スケジュールに対応しながら、高い品質基準を維持できます。

さらに、先進的な 自動車プレス機 技術は、欠陥の少ない高品質な部品の生産を保証します。これは、部品が厳しい安全基準や規制基準を満たす必要がある自動車業界では特に重要です。 金属圧延サービス また、コストを削減しながら品質を維持し、メーカーが競争力を保つことを可能にします。

自動車生産におけるコストと時間の効率化

の利用により 金属スタンプ自動車 テクノロジー プレス部品メーカー 自動車部品の生産において大幅な時間とコストの削減が実現できます。それがどの用途であっても 車体 または チャシス 部品に対しては、 metal stamping parts 信頼性が高く効率的な解決策を提供し、自動車業界の高い基準を満たします。

結論:自動車製造における金属プレス加工の未来

自動車業界が進化するにつれて、高性能の 金属スタンプ自動車 部品に対する需要はさらに増加していきます。の技術開発により 自動車プレス機 より複雑で高強度の部品を低コストで生産することが可能になります。どの用途においても プレス部品メーカー 自動車製造において引き続き重要です。 車体 または チャシス , metal stamping parts は

産業がより持続可能で軽量な車両へと移行する中で、 金属圧延サービス これらの要求を満たすためにますます重要な役割を果たします。革新的なソリューションと高品質な生産を提供することにより、 金属プレス加工 自動車製造の未来を引き続き形作っていきます。

少量のバッチ、高い基準。私たちの迅速なプロトタイピングサービスにより、検証がより速く簡単になります——

少量のバッチ、高い基準。私たちの迅速なプロトタイピングサービスにより、検証がより速く簡単になります——